Lapped bevel gears are the most regular bevel gear types used in gearmotors and reducers .The difference comparing with ground bevel gears ,both has their advantages and disadvantages .

Ground bevel gears Advantages:

1. The tooth surface roughness is good. By grinding the tooth surface after heat, the surface roughness of the finished product can be guaranteed to be above 0.

2. High precision grade. The gear grinding process is mainly to correct the deformation of the gear during the heat treatment process, to ensure the accuracy of the gear after completion, without vibration during high-speed (above 10,000 rpm) operation, and to achieve the purpose of precise control of the gear transmission;

Ground bevel gears Disadvantages:

1. High cost. Gear grinding requires multiple machine tools, and the cost of each gear grinding machine is more than 10 million yuan. The production process is also expensive. There is a constant temperature workshop. The cost of a grinding wheel is several thousand, and there are filters, etc., so the grinding is more expensive, and the cost of each set is about 600 yuan;

2. Low efficiency and limited by gear system. Bevel gear grinding is carried out on multiple machine tools, and the grinding time is at least 30 minutes. And can not grind the teeth;

3. Reduce the performance of the product. In terms of product performance, the gear grinding process removes the best layer of gear surface hardening quality after heat treatment, and it is this layer of hard shell that determines the service life of the gear. Therefore, developed countries like Japan do not grind the bevel gears for automobiles at all.

Lapped bevel gears advantages and disadvantages

1. High efficiency. It only takes about 5 minutes to grind a pair of gears, which is suitable for mass production.

2. The noise reduction effect is good. Lapping teeth are processed in pairs, and the conjugation of the tooth surfaces is good. The incoming surface greatly solves the noise problem and the noise reduction effect is about 3 decibels lower than that of grinding teeth

3. Low cost. Gear lapping only needs to be done on one machine tool, and the value of the machine tool itself is also lower than that of the gear grinding machine. The auxiliary materials used are also lower than those required for tooth grinding

4. Not limited by tooth profiles. It is precisely because the teeth cannot be ground that after 1995, Olycon successfully invented the grinding technology, which can not only process the teeth of equal heights, but also process shrinkage teeth .And this technique did not destroy the quench-hardened surface layer.

If you are buying your lapped bevel gears ,what kind of reports you should get from your supplier ? Below are ours which will be shared to customers before every shipping .

1. Bubble drawing :we signed NDA with every customer ,so we make drawing fuzzy

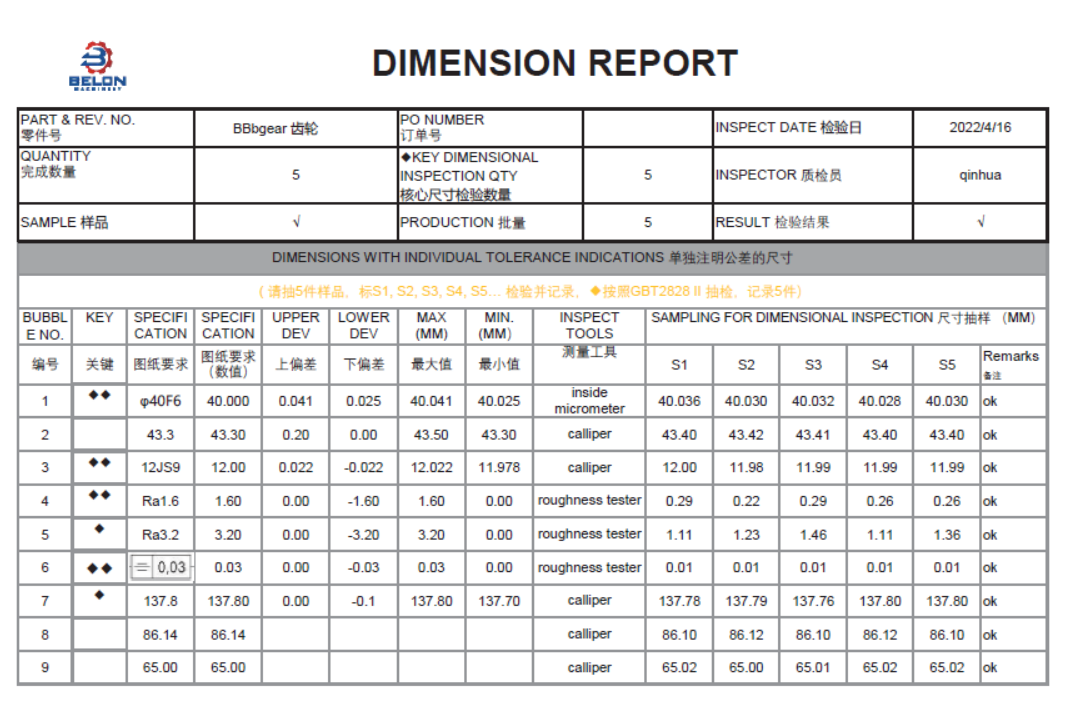

2. Key Dimension Report

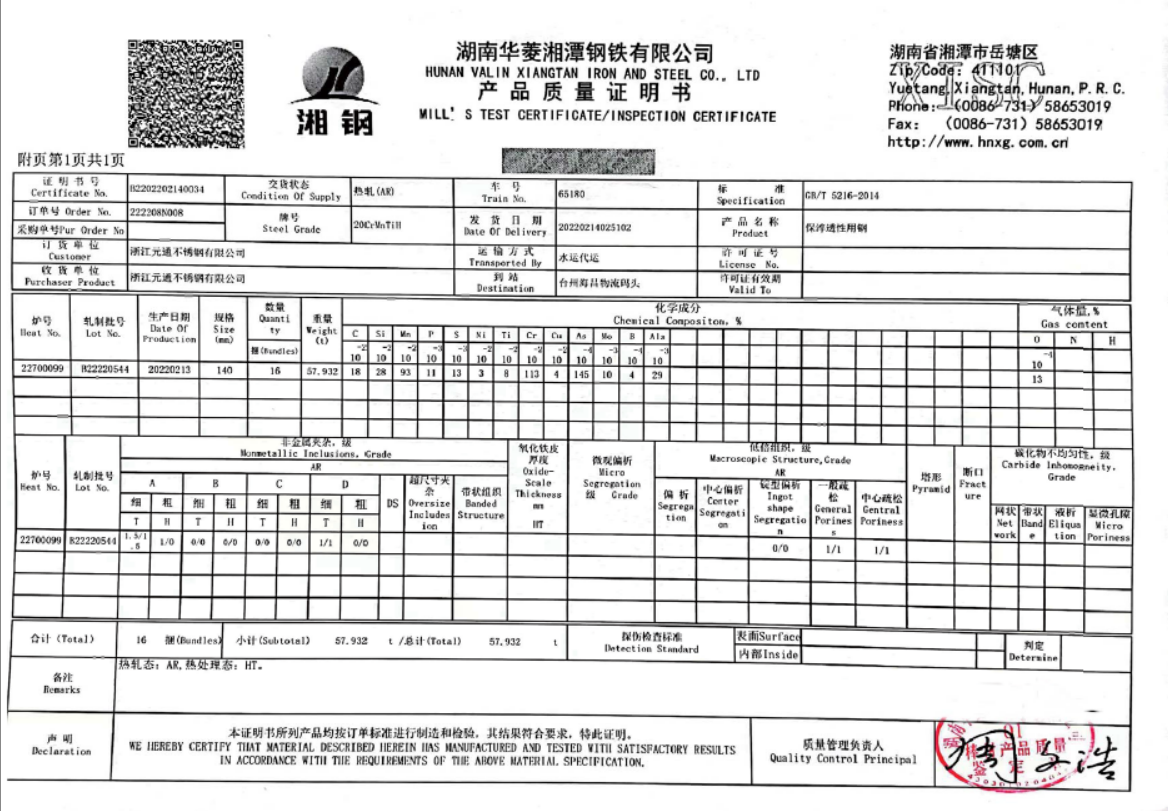

3. Material Cert

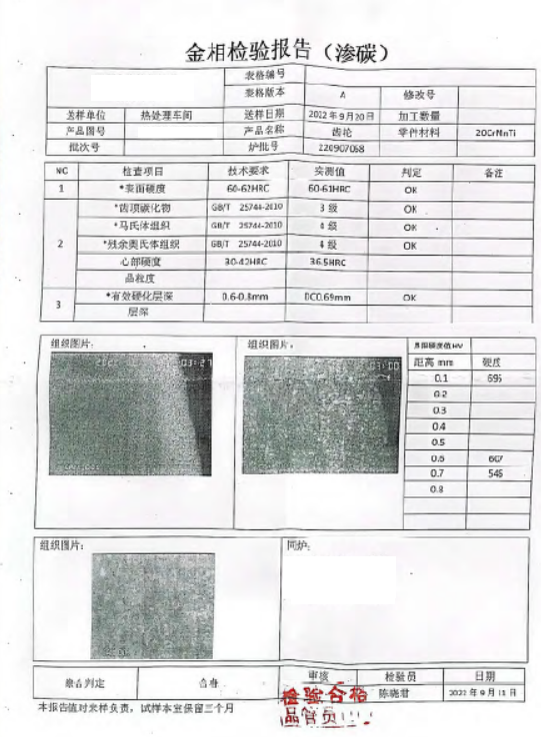

4. Heat Treat Report

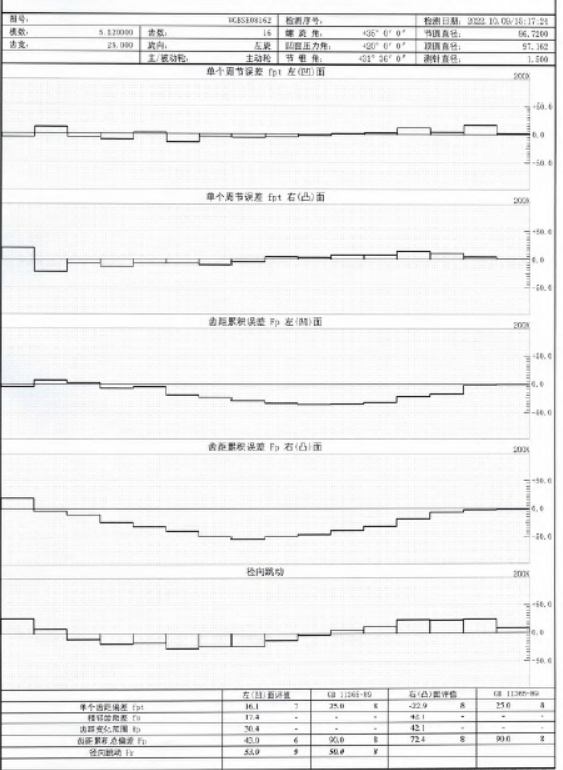

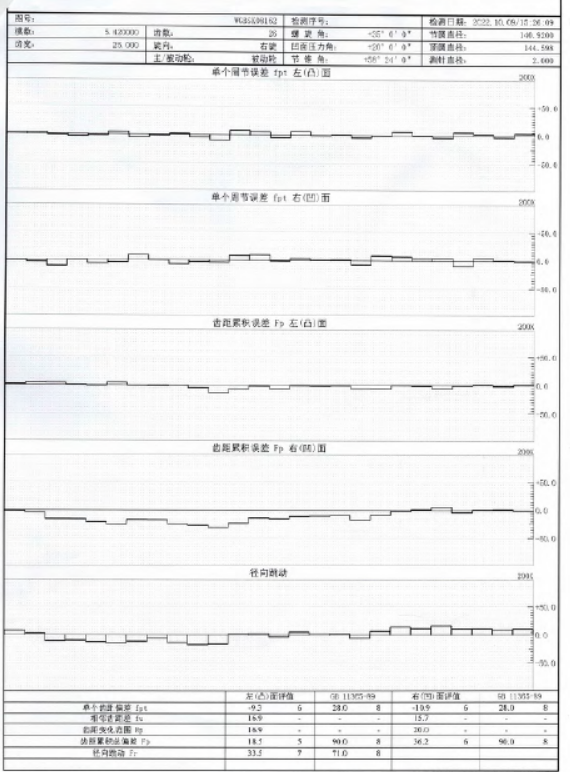

5. Accuracy Report

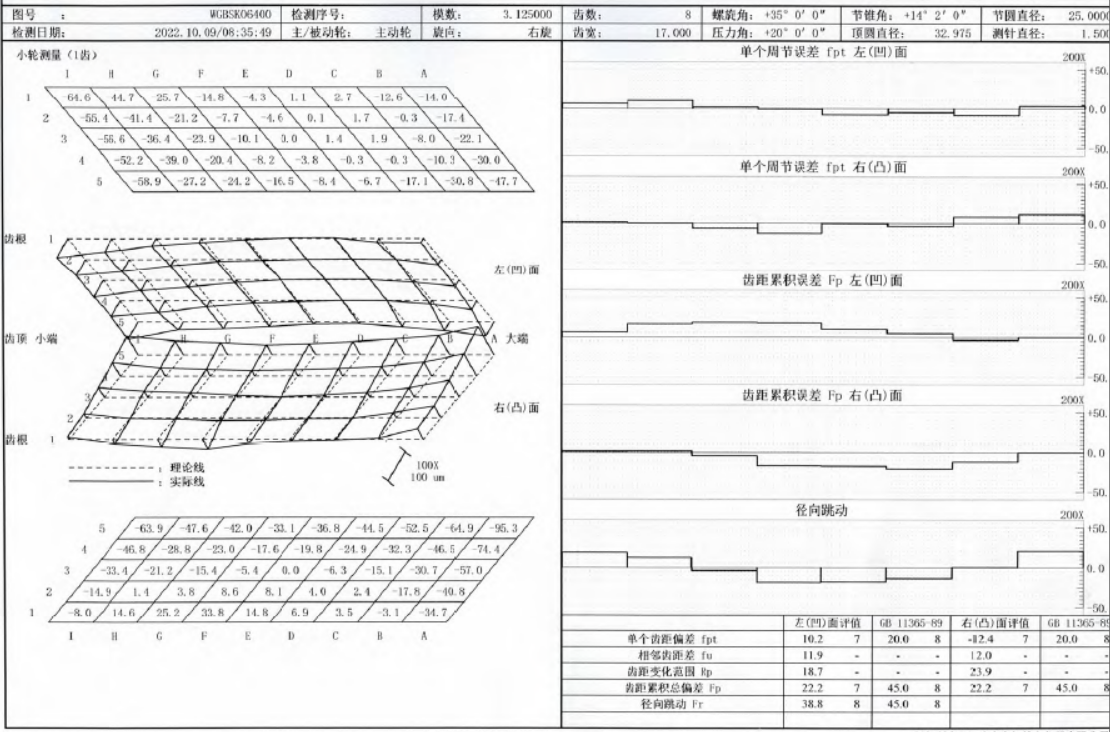

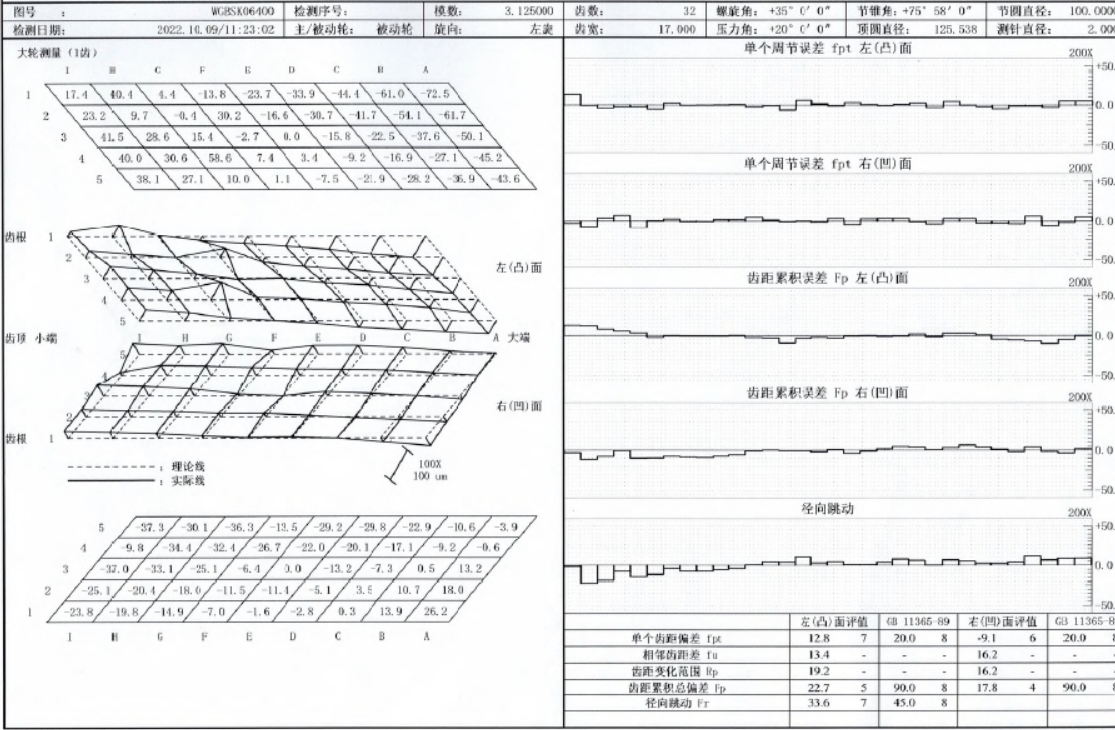

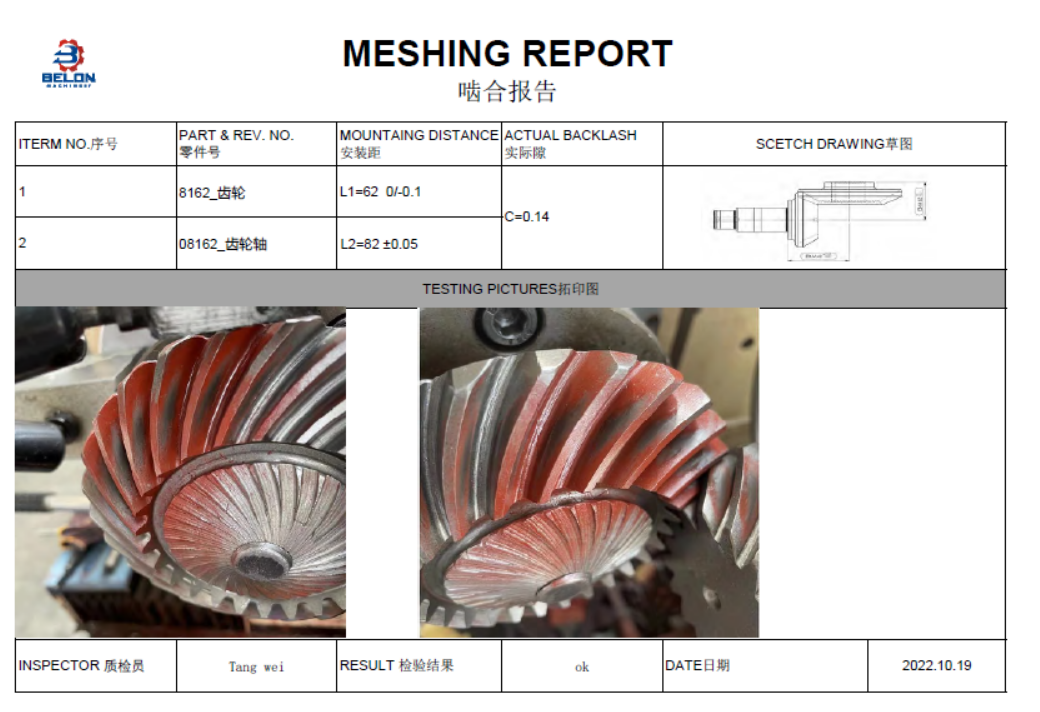

6. Meshing Report

Along with some testing videos which you could check at below link

meshing test for lapping bevel gear -center distance and backlash test

https://youtube.com/shorts/5cMDyHXMvf0

surface runout testing | for the bearing surface on bevel gears

https://youtube.com/shorts/Y1tFqBVWkow

Post time: Nov-03-2022