Many parts of the new energy reducer gears and automotive gears project require shot peening after gear grinding, which will deteriorate the quality of the tooth surface, and even affect the NVH performance of the system. This paper studies the tooth surface roughness of different shot peening process conditions and different parts before and after shot peening. The results show that shot peening will increase the tooth surface roughness, which is affected by the characteristics of parts, shot peening process parameters and other factors; Under the existing batch production process conditions, the maximum tooth surface roughness after shot peening is 3.1 times that before shot peening. The influence of tooth surface roughness on NVH performance is discussed, and the measures to improve the roughness after shot peening are proposed.

Under the above background, this paper discusses from the following three aspects:

Influence of shot peening process parameters on tooth surface roughness;

The amplification degree of shot peening on tooth surface roughness under the existing batch production process conditions;

Impact of increased tooth surface roughness on NVH performance and measures to improve the roughness after shot peening.

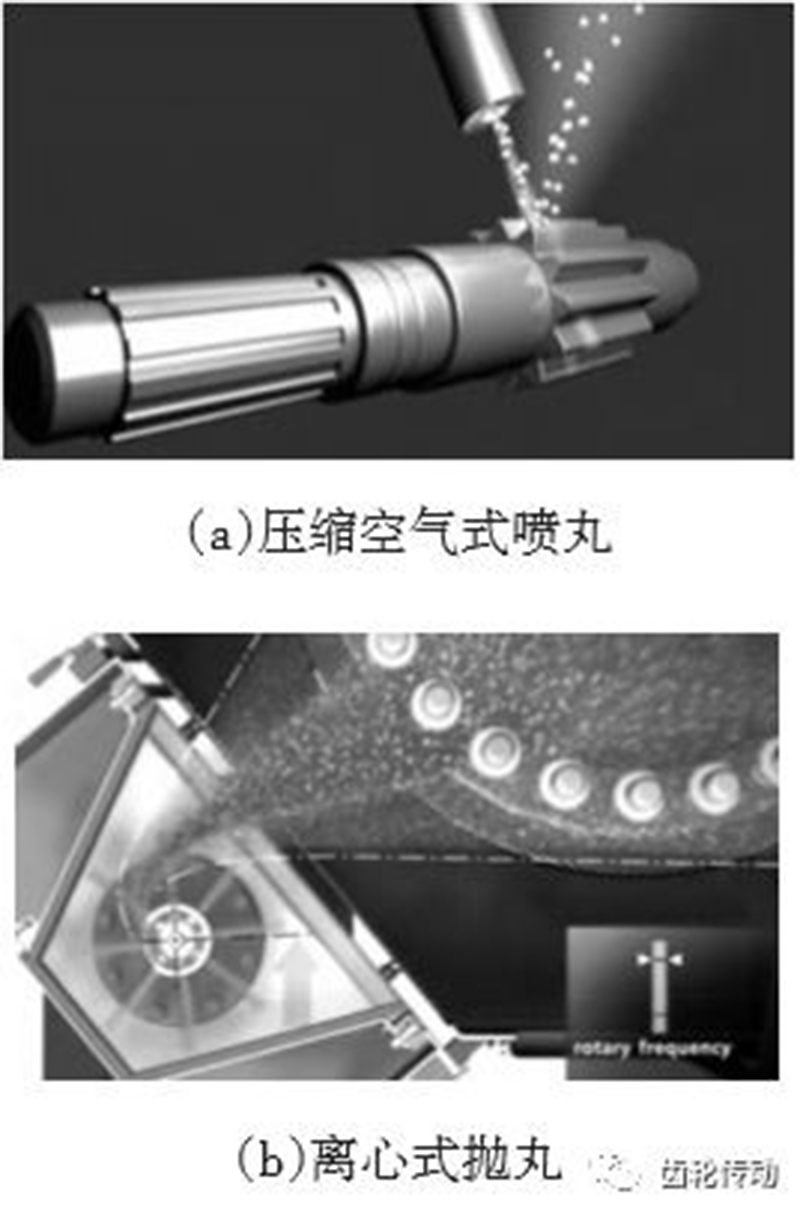

Shot peening refers to the process in which numerous small projectiles with high hardness and high-speed movement hit the surface of parts. Under the high-speed impact of the projectile, the surface of the part will produce pits and plastic deformation will occur. The organizations around the pits will resist this deformation and generate residual compressive stress. The overlapping of numerous pits will form a uniform residual compressive stress layer on the surface of the part, thus improving the fatigue strength of the part. According to the way of obtaining high speed by shot, shot peening is generally divided into compressed air shot peening and centrifugal shot peening, as shown in Figure 1.

Compressed air shot peening takes compressed air as power to spray the shot from the gun; Centrifugal shot blasting uses a motor to drive the impeller to rotate at a high speed to throw the shot. The key process parameters of shot peening include saturation strength, coverage and shot peening medium properties (material, size, shape, hardness). Saturation strength is a parameter to characterize the shot peening strength, which is expressed by the arc height (i.e. the bending degree of Almen test piece after shot peening); Coverage rate refers to the ratio of the area covered by the pit after shot peening to the total area of the shot peened area; Commonly used shot peening media include steel wire cutting shot, cast steel shot, ceramic shot, glass shot, etc. The size, shape and hardness of shot peening media are of different grades. The general process requirements for transmission gear shaft parts are shown in Table 1.

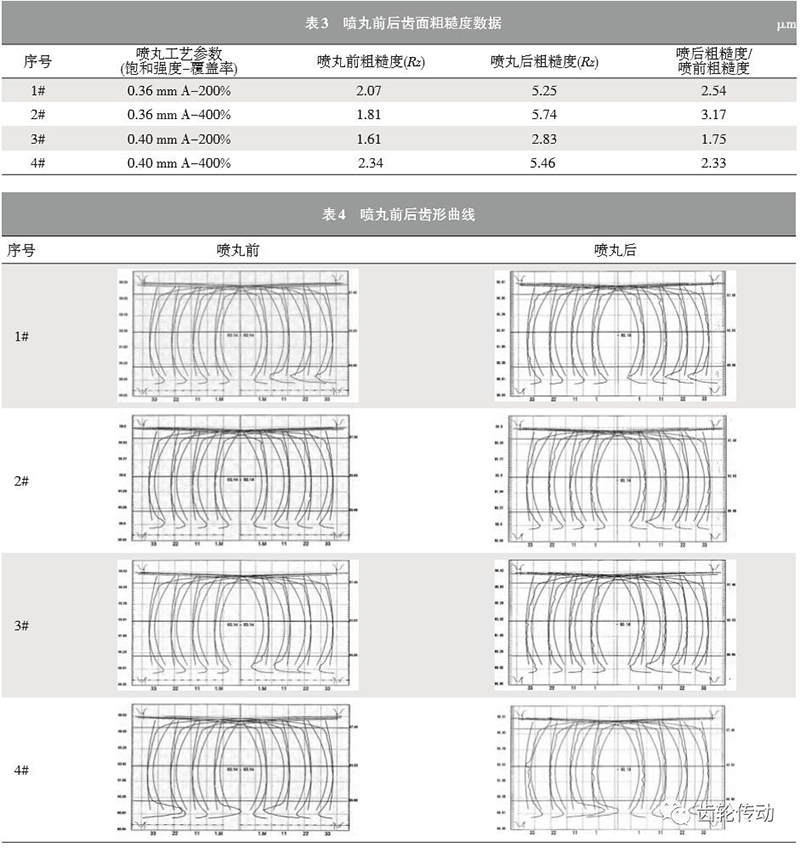

The test part is the intermediate shaft gear 1/6 of a hybrid project. The gear structure is shown in Figure 2. After grinding, the tooth surface microstructure is Grade 2, the surface hardness is 710HV30, and the effective hardening layer depth is 0.65mm, all within the technical requirements. The tooth surface roughness before shot peening is shown in Table 3, and the tooth profile accuracy is shown in Table 4. It can be seen that the tooth surface roughness before shot peening is good, and the tooth profile curve is smooth.

Test plan and test parameters

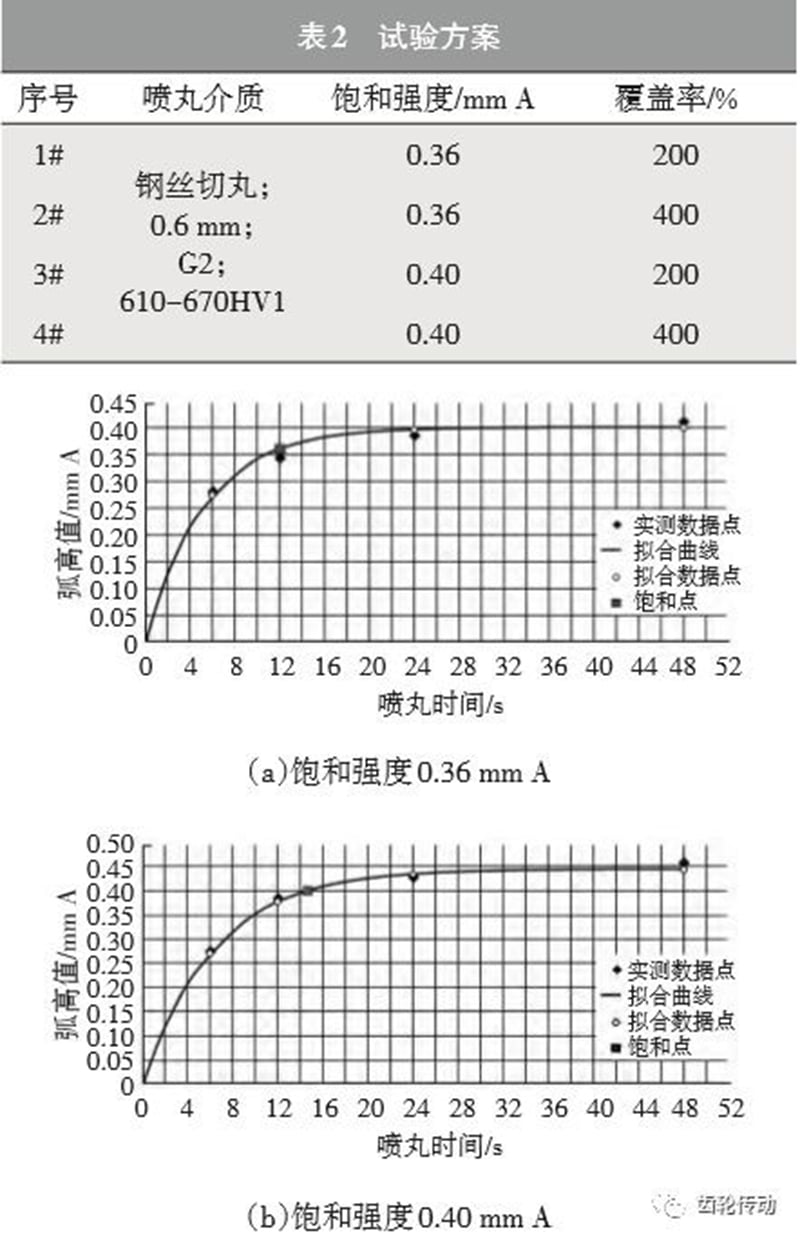

Compressed air shot peening machine is used in the test. Due to the test conditions, it is impossible to verify the impact of shot peening medium properties (material, size, hardness). Therefore, the properties of shot peening medium are constant in the test. Only the impact of saturation strength and coverage on the tooth surface roughness after shot peening is verified. See Table 2 for the test scheme. The specific determination process of test parameters is as follows: draw the saturation curve (Figure 3) through Almen coupon test to determine the saturation point, so as to lock the compressed air pressure, steel shot flow, nozzle moving speed, nozzle distance from parts and other equipment parameters.

test result

The tooth surface roughness data after shot peening is shown in Table 3, and the tooth profile accuracy is shown in Table 4. It can be seen that under the four shot peening conditions, the tooth surface roughness increases and the tooth profile curve becomes concave and convex after shot peening. The ratio of the roughness after spraying to the roughness before spraying is used to characterize the roughness magnification (Table 3). It can be seen that the roughness magnification is different under the four process conditions.

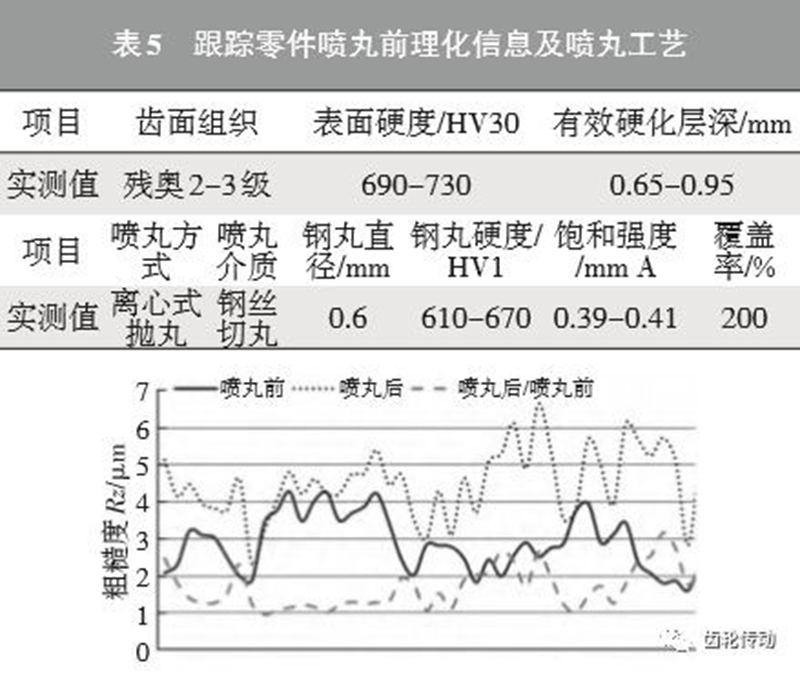

Batch Tracking of Magnification of Tooth Surface Roughness by Shot Peening

The test results in Section 3 show that the tooth surface roughness increases in varying degrees after shot peening with different processes. In order to fully understand the amplification of shot peening on tooth surface roughness and increase the number of samples, 5 items, 5 types and 44 parts in total, were selected to track the roughness before and after shot peening under the conditions of batch production shot peening process. See Table 5 for the physical and chemical information and shot peening process information of tracked parts after gear grinding. Roughness and magnification data of front and rear tooth surfaces before shot peening are shown in Fig. 4. Figure 4 shows that the range of tooth surface roughness before shot peening is Rz1.6 μ m-Rz4.3 μ m; After shot peening, the roughness increases, and the distribution range is Rz2.3 μ m-Rz6.7 μ m; The maximum roughness can be amplified to 3.1 times before shot peening.

Influencing factors of tooth surface roughness after shot peening

It can be seen from the principle of shot peening that the high hardness and high-speed moving shot leaves innumerable pits on the part surface, which is the source of residual compressive stress. At the same time, these pits are bound to increase the surface roughness. The characteristics of the parts before shot peening and the shot peening process parameters will affect the roughness after shot peening, as listed in Table 6. In Section 3 of this paper, under the four process conditions, the tooth surface roughness after shot peening increases to different degrees. In this test, there are two variables, namely, pre shot roughness and process parameters (saturation strength or coverage), which can not accurately determine the relationship between post shot peening roughness and each single influencing factor. At present, many scholars have done research on this, and put forward a theoretical prediction model of surface roughness after shot peening based on finite element simulation, which is used to predict the corresponding roughness values of different shot peening processes.

Based on the actual experience and the research of other scholars, the influence modes of various factors can be speculated as shown in Table 6. It can be seen that the roughness after shot peening is comprehensively affected by many factors, which are also the key factors affecting the residual compressive stress. In order to reduce the roughness after shot peening on the premise of ensuring the residual compressive stress, a large number of process tests are required to continuously optimize the parameter combination.

Influence of tooth surface roughness on NVH performance of the system

Gear parts are in the dynamic transmission system, and the tooth surface roughness will affect their NVH performance. The experimental results show that under the same load and speed, the greater the surface roughness, the greater the vibration and noise of the system; When the load and speed increase, the vibration and noise increase more obviously.

In recent years, the projects of new energy reducers have increased rapidly, and show the development trend of high speed and large torque. At present, the maximum torque of our new energy reducer is 354N · m, and the maximum speed is 16000r/min, which will be increased to more than 20000r/min in the future. Under such working conditions, the influence of the increase of tooth surface roughness on the NVH performance of the system must be considered.

Improvement measures for tooth surface roughness after shot peening

The shot peening process after gear grinding can improve the contact fatigue strength of the gear tooth surface and the bending fatigue strength of the tooth root. If this process must be used due to strength reasons in the gear design process, in order to give consideration to the NVH performance of the system, the roughness of the gear tooth surface after shot peening can be improved from the following aspects:

a. Optimize the shot peening process parameters, and control the amplification of tooth surface roughness after shot peening on the premise of ensuring the residual compressive stress. This requires a lot of process tests, and the process versatility is not strong.

b. The composite shot peening process is adopted, that is, after the normal strength shot peening is completed, another shot peening is added. The increased shot peening process strength is usually small. The type and size of shot materials can be adjusted, such as ceramic shot, glass shot or steel wire cut shot with smaller size.

c. After shot peening, processes such as tooth surface polishing and free honing are added.

In this paper, the tooth surface roughness of different shot peening process conditions and different parts before and after shot peening is studied, and the following conclusions are drawn based on literature:

◆ Shot peening will increase the tooth surface roughness, which is affected by the characteristics of parts before shot peening, shot peening process parameters and other factors, and these factors are also the key factors affecting the residual compressive stress;

◆ Under the existing batch production process conditions, the maximum tooth surface roughness after shot peening is 3.1 times that before shot peening;

◆ The increase of tooth surface roughness will increase the vibration and noise of the system. The greater the torque and speed, the more obvious the increase of vibration and noise;

◆ The tooth surface roughness after shot peening can be improved by optimizing the shot peening process parameters, composite shot peening, adding polishing or free honing after shot peening, etc. The optimization of the shot peening process parameters is expected to control the roughness amplification to about 1.5 times.

Post time: Nov-04-2022