The meshing pair of involute worm and involute helical gear has been widely used in low-power transmission. This kind of meshing pair is relatively easy to design and produce. In production, if the accuracy of parts is slightly poor or the requirements for transmission ratio are not very strict, it is also a good selection method.

At present, this kind of transmission pair is not included in the general design data because its theory is not yet fully mature.

This kind of meshing pair is a typical point contact transmission pair. From the microscopic point of view, the local stress is large and the efficiency is low. Fortunately, the transmission torque is small and the requirements for efficiency are low. Therefore, it is quite marketable. Such a design avoids various problems existing in the manufacturing and assembly of worm gears.

This paper mainly discusses the representation of this kind of contact pair moving along the normal direction in a very small range by using an animation in the moving direction of the contact point.

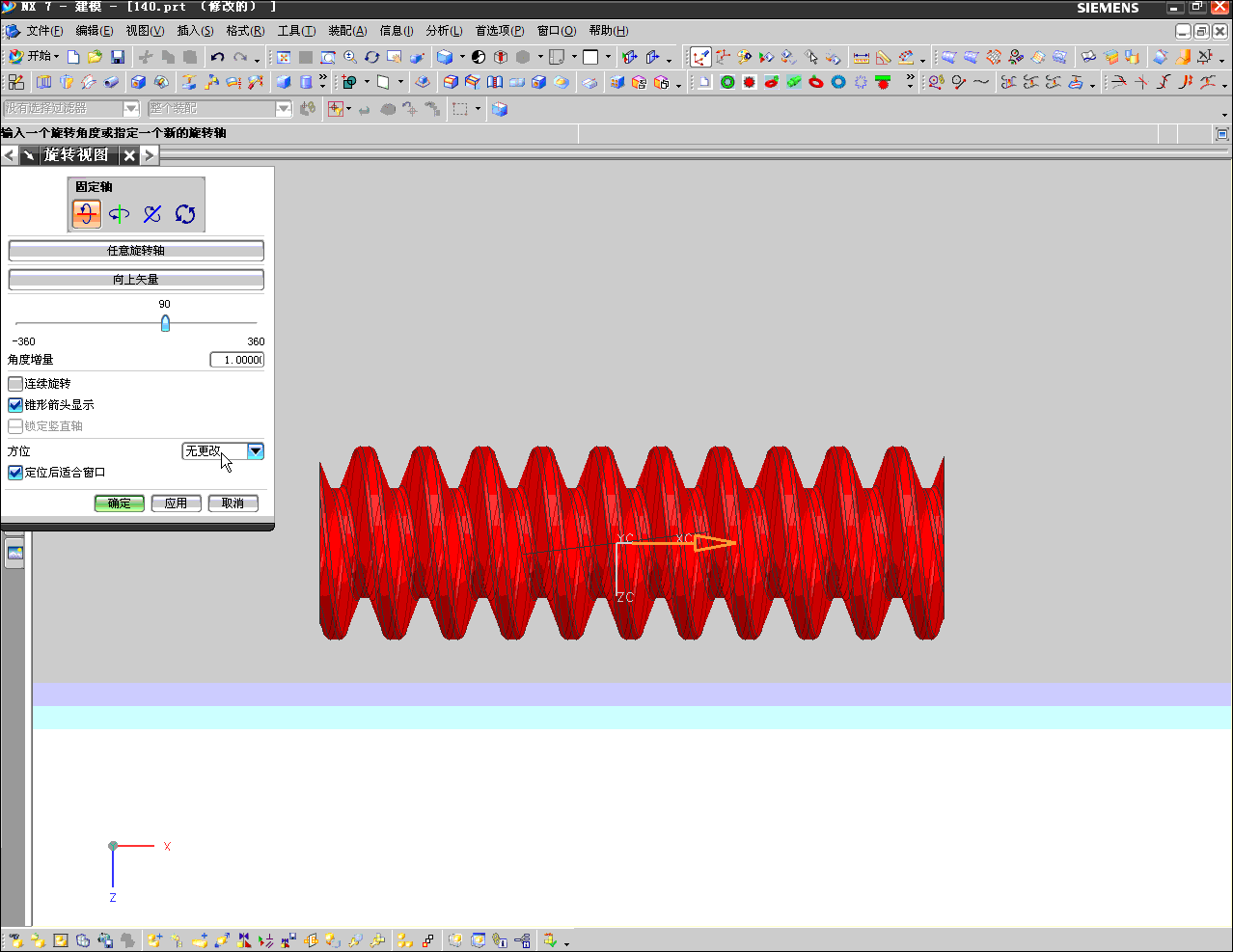

Make a plane on the middle section of the meshing pair on the drawing, and process it into translucent and contrasting color on the drawing, and then let it rotate a worm rising angle around the vertical line from the gear center to the worm, which is located at the position of the normal plane, as shown in the following figure:

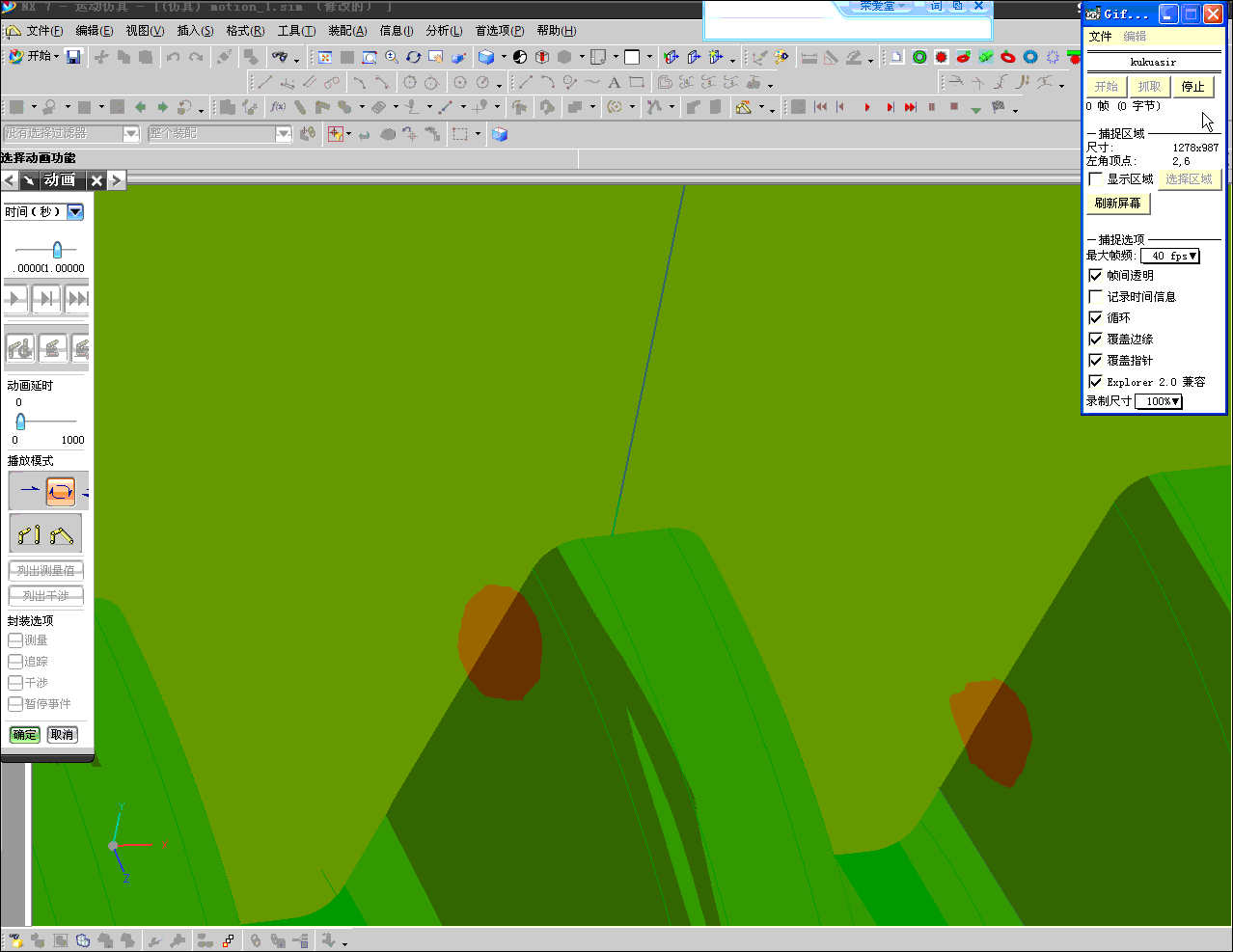

After treatment, take the transmission pair that needs to check the meshing marks into a contrast color, and take one of them as translucent, so that the movement of the meshing position in the whole process of dynamic simulation can be clearly seen. As shown below:

During the movement of the meshing contact point with obvious contrast color, it can be seen that it passes through the normal sheet.

Records calculated in the above example:

Preliminary calculation record of involute worm with helical gear

input data

Normal modulus: 6 worm indexing circle diameter: 5 worm head number: 1 helical gear tooth number: 40

Normal pressure angle: 20 helical gear preselection helix angle: 6.89210257934639

Calculation data

Normal modulus: six

Axial modulus: six hundred and four trillion and three hundred and sixty-seven billion two hundred and twenty-three million nineteen thousand and thirty-five

Thread rising angle: 6.89210257934639

Spiral direction: the worm and helical gear are in the same direction

Center distance of zero displacement: 14.5873444603807

Center distance of input transmission pair: 14.75

Equivalent number of screw teeth: 8.27311576399391

Worm axial pressure angle: 20.1339195068419

Radial deflection coefficient of helical gear: two thousand seven hundred and eleven

Worm helix angle: 83.1078974206537

Basic parameters of worm 83.10789742065361

Worm major diameter: 6.2 worm minor diameter: 3.5 worm tooth number: 1

Worm normal modulus: 6 worm normal pressure angle: 20 worm indexing circle diameter: 5

Worm radial displacement coefficient: 0 worm base circle diameter: 1.56559093858108

Worm end module: 5 worm axial module: six hundred and four trillion and three hundred and sixty-seven billion two hundred and twenty-three million nineteen thousand and thirty-five

Worm axial pressure angle: 20.1339195068419 worm end face pressure angle: 71.752752179164

Normal tooth thickness of worm indexing circle: 942477796076937 measuring tooth height of worm indexing circle: six

Worm indexing circle thread rising angle: 6.89210257934639 worm indexing circle helix angle: 83.1078974206537

Effective tooth length of worm: 25

Worm (axial) lead: 1.89867562790706

Basic parameters of helical gear

Major diameter of helical gear: 25.7 minor diameter of helical gear: 23 number of teeth of helical gear: 40

Normal modulus of helical gear: 6 helical gear normal pressure angle: 20 helical gear modification coefficient: two thousand seven hundred and eleven

Helical gear indexing circle diameter: 24.1746889207614 helical gear base circle diameter: 22.69738911811

Module of helical gear end face: 604367223019035 helical gear end face pressure angle: 20.1339195068419

Helical angle of helical gear indexing circle: 6.89210257934639 helical gear width: 10

Helical gear (axial) lead: 628.318530717958

Number of teeth across common normal line of helical gear: 5 nominal value of common normal line of helical gear: 8.42519

Number of teeth across common normal line of helical gear: 6 nominal value of common normal line of helical gear: 10.19647

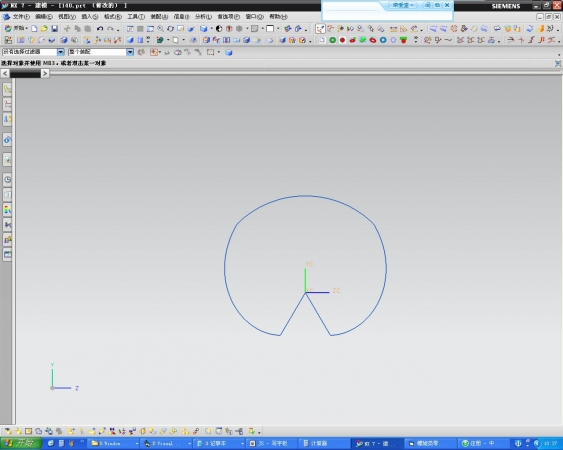

End face involute line diagram used for modeling involute worm:

Post time: Jun-11-2022