-

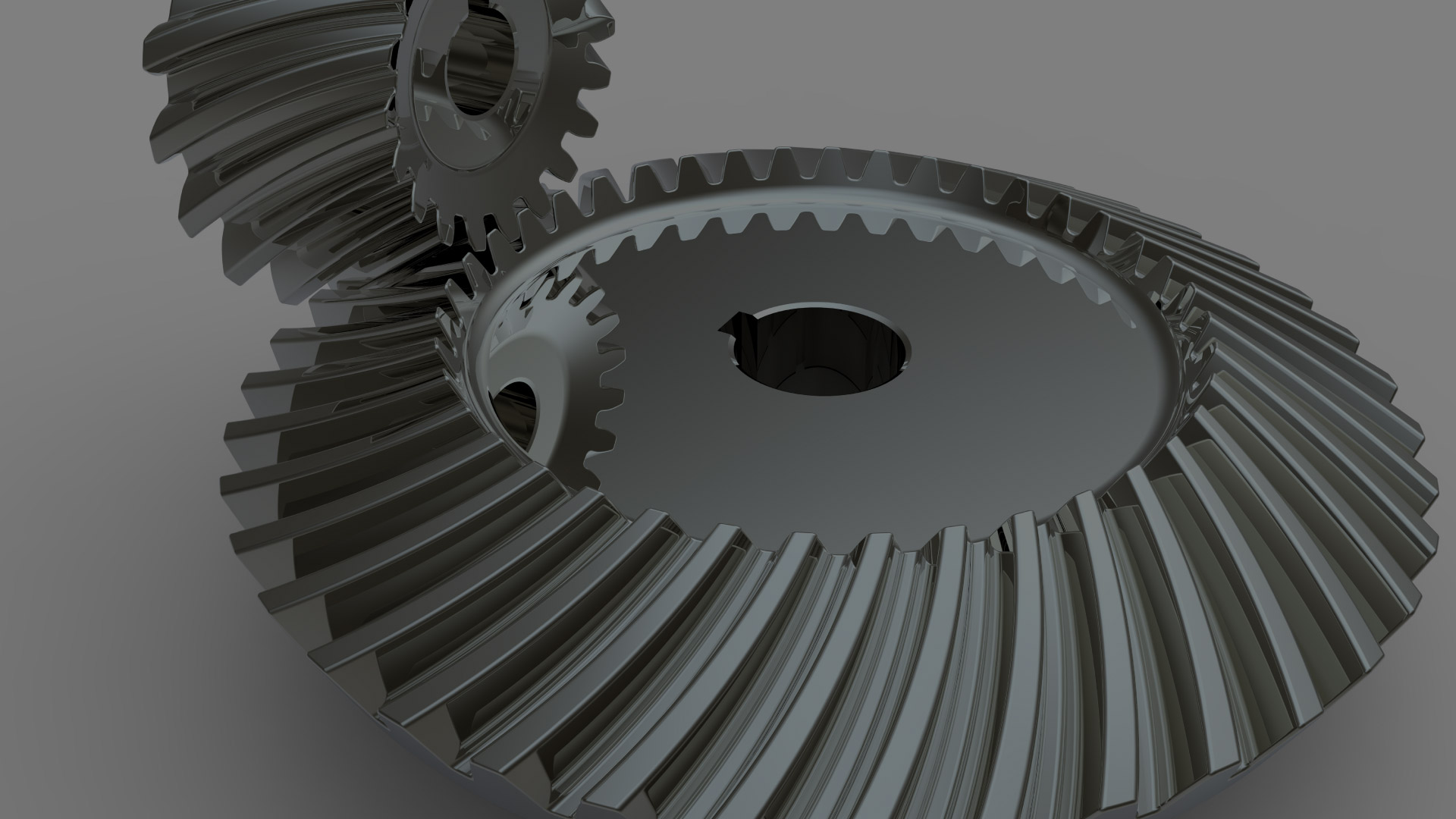

What is the reason behind using spiral bevel gears in accessory gearbox design?

Spiral bevel gears are commonly used in accessory gearbox design for several reasons: 1. Efficiency in Power Transmission: Spiral bevel gears offer high efficiency in power transmission. Their tooth configuration allows for smooth and gradual contact between teeth, minimizing friction and energy ...Read more -

Have You Discovered the Unmatched Precision and Durability of Our High Precision Spiral Bevel Gear Set

In the dynamic world of mechanical engineering, where precision is paramount and reliability is non-negotiable, our High Precision Spiral Bevel Gear Set stands as a testament to superior craftsmanship and cutting-edge materials. At the heart of this exceptional gear set lies the use of premium 18...Read more -

why planet carrier is important in the planetary gearbox system?

In a planetary gearbox system, the planet carrier plays a crucial role in the overall function and design of the gearbox. A planetary gearbox consists of several components, including a sun gear, planet gears, a ring gear, and the planet carrier. Here’s why the planet carrier is important: ...Read more -

Explore the role of miter gears in machinery

Miter gears assume a vital role in machinery as they serve as essential components for transmitting power between shafts that intersect at a right angle. The design of these gears allows for a right-angle change in the direction of rotation, making them suitable for various applications. HereR...Read more -

How miter gears are used in automotive applications

Miter gears play a crucial role in automotive applications, particularly in the differential system, where they contribute to the efficient transmission of power and enable the proper functioning of vehicles. Here’s a detailed discussion on how miter gears are used in the automotive industr...Read more -

Spiral bevel gear more often used in main gearboxes, Why?

一. Basic Structure of Bevel Gear Bevel gear is a rotary mechanism used to transmit power and torque, usually composed of a pair of bevel gears. The bevel gear in the main gearbox consists of two parts: the large bevel gear and the small bevel gear, which are located on the input shaft and output...Read more -

Bevel gear Inspection

Gear is an essential part of our production activities, the quality of the gear directly affects the operating speed of machinery. Hence, there is also a need to inspect gears. Inspecting bevel gears involves evaluating all aspects of the gear to ensure it is in proper working order. For example:...Read more -

Bevel gear reverse engineering

Bevel gear reverse engineering Reverse engineering a gear involves the process of analyzing an existing gear to understand its design, dimensions, and features in order to recreate or modify it. Here are the steps to reverse engineer a gear: Acquire the gear: Obtain the physical gear that...Read more -

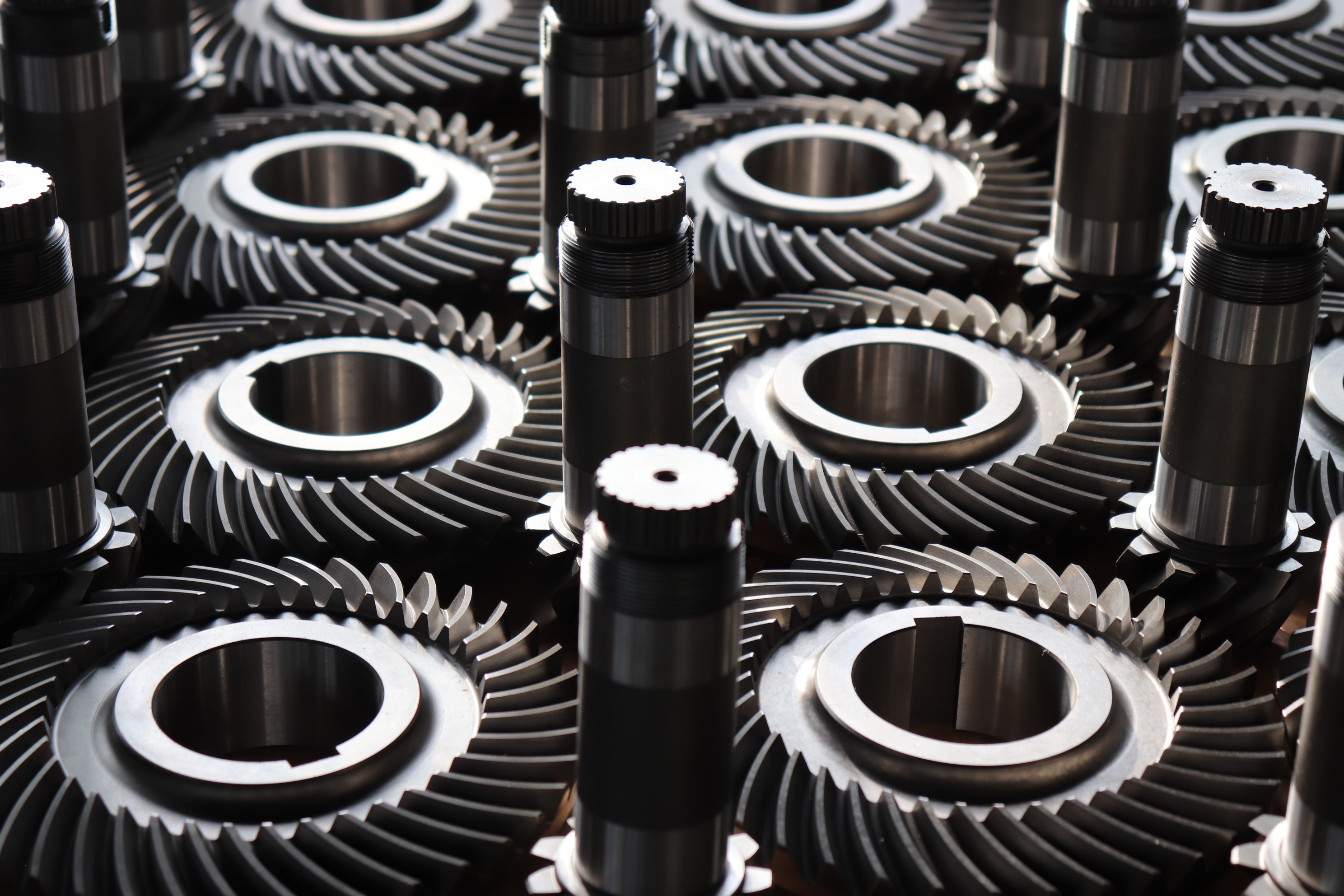

Lapped bevel gears production process

Lapped bevel gears production process The production process of lapped bevel gears involves several steps to ensure accuracy and quality. Here is a general overview of the process: Design: The first step is to design the bevel gears according to the specific requirements of the application...Read more -

Exploring the World of Worm Gears

Looking to achieve significant speed reductions in your machinery? Worm gears might just be the solution you need. Worm gears are renowned for their ability to provide substantial speed reductions, making them a go-to choice in various industries. The key to their reduction magic lies in the n...Read more -

Features of ground bevel gear teeth and lapped bevel gear teeth

Features of ground bevel gear teeth and lapped bevel gear teeth Features of lapped bevel gear teeth Due to the shorter gearing times, lapped gearings in mass production are mostly manufactured in a continuous process (face hobbing). These gearings are characterized by a constant tooth d...Read more -

Powder metallurgy gears

Powder metallurgy gears Powder metallurgy is a manufacturing prat involves compacting metal powders under high pressure and then sintering them at high temperatures to form solid parts. Powder metal gears are widely used in various industries such as automotive, industrial equipment and po...Read more