As the global push for renewable energy accelerates, the demand for reliable and durable components in wind power systems has never been higher. Belon Gear is proud to announce the successful development and delivery of custom high strength gears for wind turbine gearbox systems, supporting the clean energy sector with world class precision and engineering.

Wind Turbine Gear Design Solutions

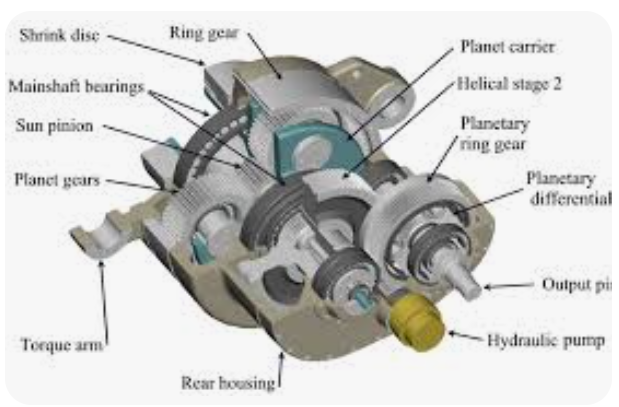

The performance and service life of wind turbines are closely tied to the quality of their gear design. Gears are fundamental components in the drivetrain, enabling the conversion of low speed rotor motion into the high speed rotation required for electricity generation. Four main gear types are commonly used in wind turbine systems: planetary gears, helical gears, bevel gears, and spur gears each chosen for specific functions within the turbine.

Spur gears with their straight tooth profiles, are a straightforward and cost effective option. Though simple in design, they tend to generate significant noise and are less suitable for high speed, high load applications.

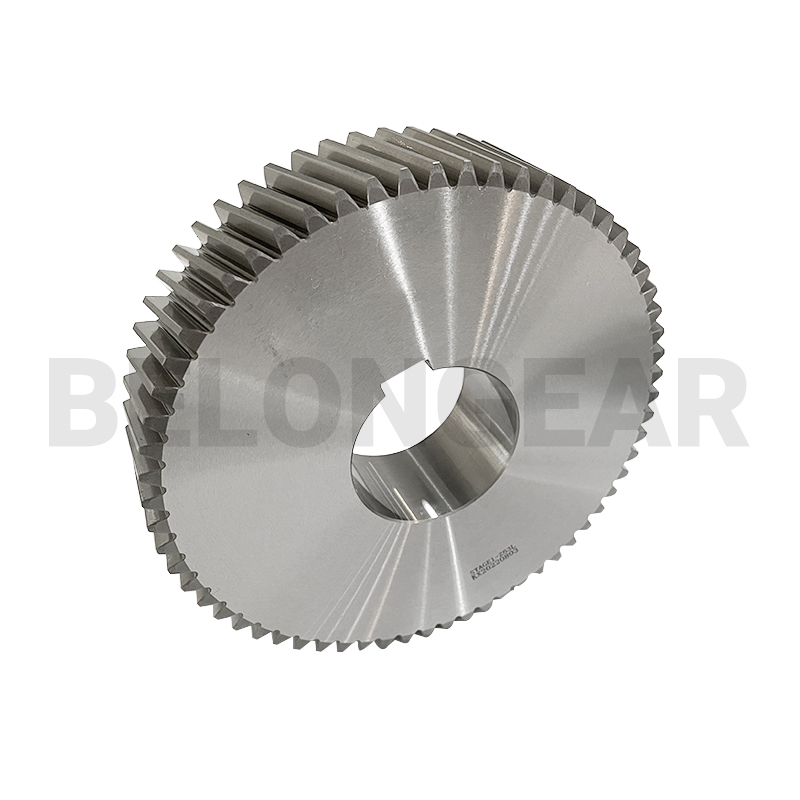

Helical gears offer an improved alternative by incorporating angled teeth, which allow for smoother meshing, greater speed capabilities, and reduced operational noise. As a result, they are widely used in wind turbine gearboxes where quieter and more efficient performance is desired.

Bevel gears are engineered to transfer motion between shafts positioned at an angle, often 90 degrees. They play a crucial role in auxiliary systems of wind turbines, such as yaw and pitch mechanisms, which adjust blade orientation and direction.

Planetary gear systems consist of a central sun gear surrounded by multiple planet gears that rotate around it. These compact, torque dense configurations are typically used in the main gearbox of large wind turbines due to their ability to handle high loads while maintaining stability and efficiency.

When designing gears for wind turbine applications, engineers must consider several critical factors: load bearing capacity, mechanical efficiency, structural strength, and acoustic performance. The gearbox must endure constant stress and torque from variable wind conditions while efficiently transmitting power to the generator. At the same time, it should be engineered to support long term operation often 20 years or more without excessive wear or performance degradation.

In addition to the gears themselves, the shaft system, bearings, lubrication, and thermal management are essential components of the gearbox assembly. The main shaft connects the rotor to the gearbox, while high performance bearings reduce friction and maintain alignment under load. Effective lubrication is required to minimize gear tooth wear and prevent overheating. Integrated cooling systems ensure thermal stability by dissipating the heat generated during high load operation.

Wind turbine gearboxes are critical for converting low speed wind energy into high speed rotational energy required by the generator. Operating under extreme loads, fluctuating wind conditions, and varying temperatures, these gear systems require exceptional durability, high torque capacity, and flawless gear meshing. Belon Gear was selected by a major renewable energy equipment manufacturer to produce a series of large diameter helical and planetary gears engineered for long service life and reduced maintenance requirements.

To meet the technical challenges of this project, our engineering team collaborated closely with the client to optimize gear material selection, tooth geometry, and surface treatment processes. The gears were manufactured using 42CrMo4 and 18CrNiMo7 6, materials known for their excellent fatigue resistance and hardenability. Advanced carburizing and grinding processes were applied to ensure tooth surface hardness above HRC 58, while maintaining core toughness essential for absorbing shock loads.

Precision is paramount in wind turbine gearboxes. Belon Gear applies strict quality control using state of the art inspection equipment including Klingelnberg gear measuring centers, CMMs, and magnetic particle testing. Each gear was thoroughly tested for profile deviation, pitch error, and surface finish, achieving gear accuracy up to DIN 6 standard, which is critical for minimizing noise and wear in high speed operations.

Additionally, our team successfully shortened the lead time by optimizing workflow and integrating our in house gear cutting, heat treatment, and final grinding facilities. The entire project, from technical review to final delivery, was completed in just 45 days, demonstrating our commitment to fast, flexible, and reliable gear manufacturing.

The delivery of these gears marks another milestone in Belon Gear’s ongoing support of the green energy sector. We are honored to contribute to the global transition toward sustainable power by providing critical drivetrain components that meet the highest standards of reliability and performance.

With increasing investments in wind power infrastructure worldwide, Belon Gear continues to expand its capabilities in large module gear production, precision machining, and material science. Our solutions are now serving wind turbine projects in Europe, South America, and Southeast Asia, delivering value through quality and engineering excellence.

At Belon Gear, we power the future of renewable energy one gear at a time

Post time: Jul-29-2025