What is a Gear Tooth?

Gears are fundamental elements in modern mechanical engineering, used in everything from clocks and automobiles to industrial machinery and aerospace systems. At the heart of every gear lies its most critical feature the gear tooth. Understanding the structure, function, and importance of gear teeth provides valuable insight into how gears transmit power efficiently and reliably across countless applications.

Definition of a Gear Tooth

A gear tooth is the individual projecting part on the circumference of a gear wheel. When two gears mesh together, their teeth interlock in a precise pattern, allowing rotational motion and torque to be transmitted from one shaft to another. Each tooth is carefully designed with a specific shape, known as the involute profile, to ensure smooth engagement, minimal friction, and consistent velocity ratios. Without properly designed teeth, gears would slip or jam, making accurate motion transmission impossible.

Structure and Geometry

The geometry of a gear tooth is carefully defined by several key parameters. The addendum refers to the height of the tooth above the pitch circle, while the dedendum is the depth below it. The pitch circle itself is an imaginary circle that represents the effective point of contact between meshing gears. Other important dimensions include the pressure angle, tooth thickness, and module or diametral pitch, which help standardize gear design across different applications.

The shape of a gear tooth is not arbitrary. The involute profile is the most common form used in modern gears because it allows gears to maintain a constant velocity ratio regardless of the distance between centers. This means that as long as gears remain properly aligned, their motion will remain smooth and efficient.

Functions of Gear Teeth

The gear tooth performs several essential functions within a mechanical system:

-

Transmission of Motion – Gear teeth interlock to transfer rotational movement between shafts.

-

Transmission of Torque – By meshing, gear teeth allow mechanical power to be transferred efficiently, enabling machines to handle heavy loads.

-

Speed and Direction Control – The size and number of gear teeth determine speed reduction or increase, as well as the direction of rotation.

-

Load Distribution – Teeth distribute contact forces evenly, reducing wear and ensuring longer service life.

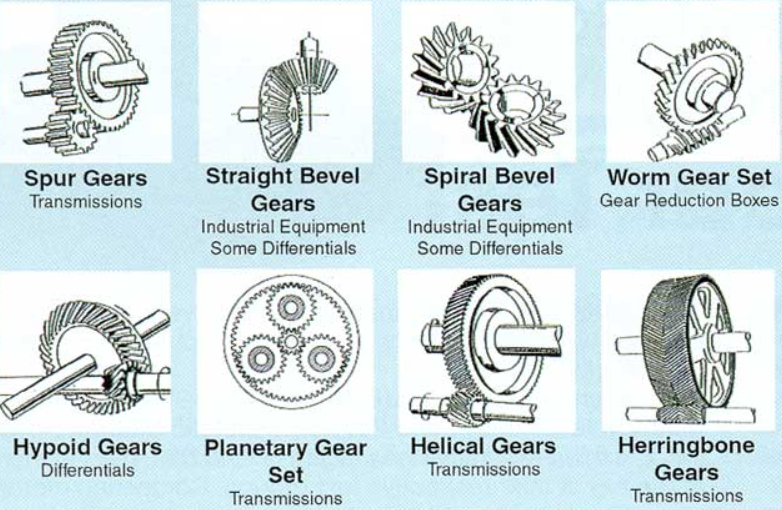

Types of Gear Teeth

Gear teeth can vary depending on the type of gear. Spur gears have straight teeth aligned parallel to the axis, making them simple but somewhat noisy at high speeds. Helical gears feature angled teeth, which engage gradually and reduce noise while allowing for higher load capacity. Bevel gears have teeth shaped to mesh at intersecting shafts, while worm gears use screw like teeth for high reduction ratios.Double Helical (Herringbone) Gears:

Composed of two rows of helical teeth with opposing angles. This configuration cancels out the axial thrust generated by single helical gears, allowing for high torque applications with greater stability

Internal Gears:

Features teeth cut on the inside of a ring or cylinder. They are used in compact designs, such as planetary gear systems, by meshing with external gears.

Rack and pinion teeth

Description: A flat bar with straight teeth (the rack) meshes with a circular gear (the pinion).

Characteristics:

Converts rotational motion into linear motion and vice versa.

Used in steering systems and linear actuator applications

Each design tailors the tooth geometry to specific applications and performance needs.

Materials and Durability

Because gear teeth endure constant stress, friction, and contact pressure, material selection is crucial. Steel alloys are widely used due to their strength and wear resistance, while surface treatments such as carburizing, nitriding, or shot peening enhance hardness and fatigue life. In lighter applications, materials such as plastics or aluminum may be used to reduce weight and noise.

Importance in Modern Engineering

The gear tooth, though small compared to the entire machine, determines the performance, efficiency, and reliability of mechanical systems. Poorly designed or manufactured gear teeth can lead to excessive vibration, noise, rapid wear, or even catastrophic failure. This is why industries place strong emphasis on precision machining, grinding, and inspection of gear teeth during production.

Post time: Sep-10-2025