Understanding Girth Gears: Powering Heavy Industry with Belon Gear

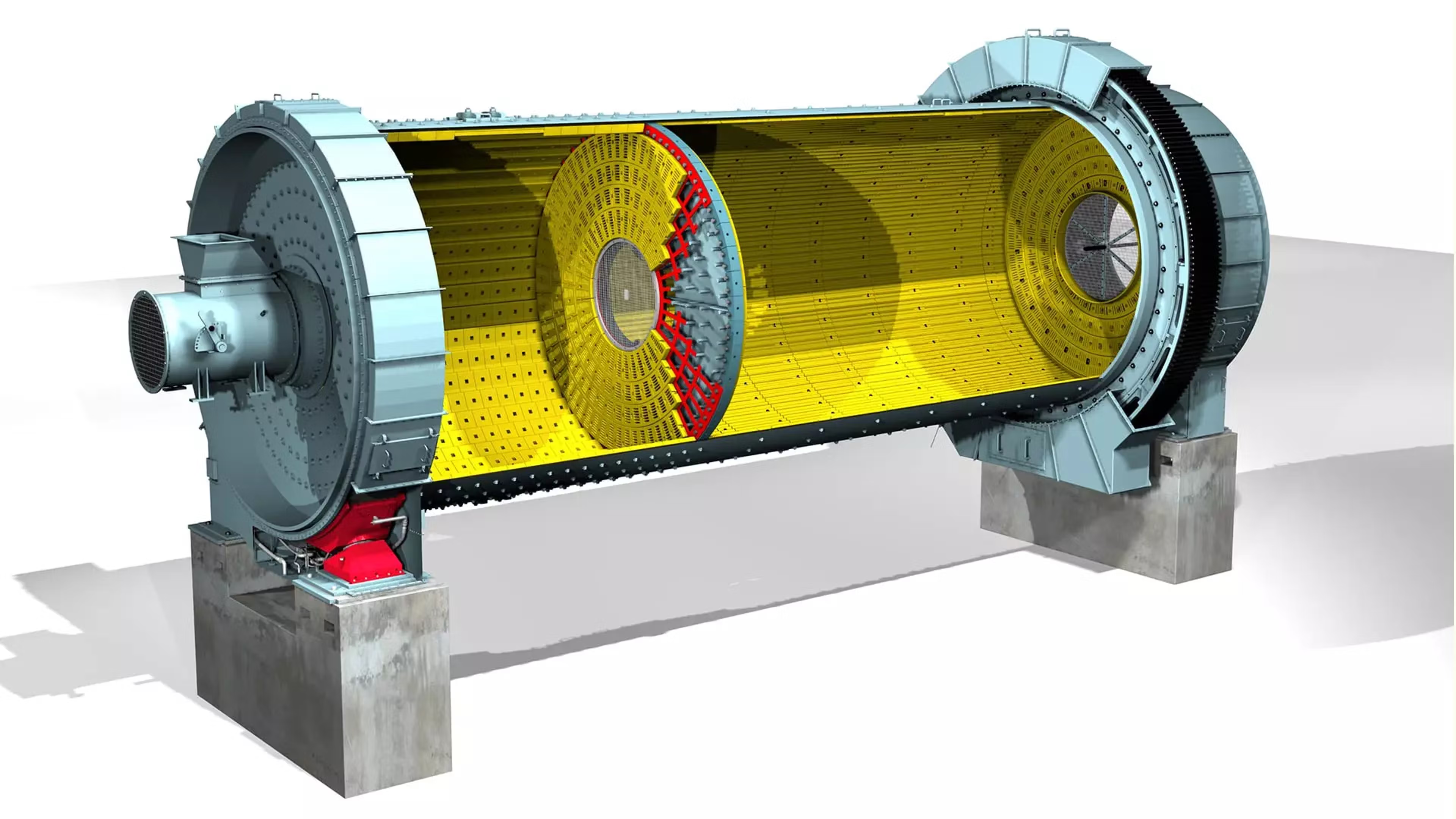

Girth gears are large diameter ring gears commonly used in heavy duty industrial machinery. They are crucial components in rotary systems such as ball mills, rotary kilns, and dryers, where they provide the torque and rotational motion necessary to operate massive mechanical assemblies. At Belon Gear, we specialize in the manufacturing of high precision girth gears that meet the demanding requirements of today’s industrial sectors.

What Are Girth Gears?

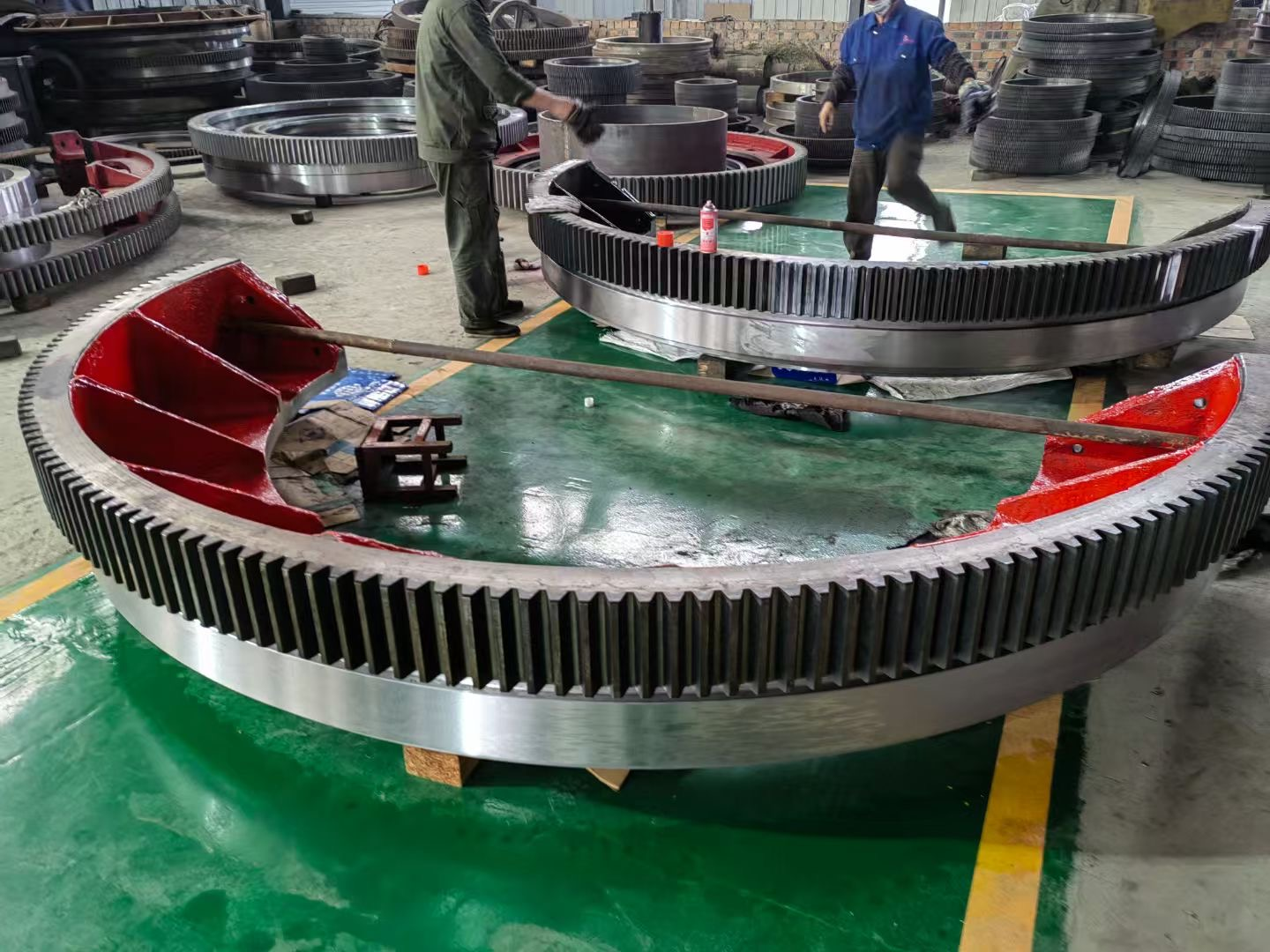

A girth gear, also known as a ring gear or a mill gear, is typically mounted on the outer circumference of a large rotating drum. These gears usually have diameters ranging from 1 meter to over 12 meters, depending on the application. Due to their sheer size and load requirements, girth gears are commonly fabricated in segments (two, four, or more sections) and then assembled on site.

Girth Gears in Heavy Machinery

They are used in applications that require slow, heavy duty torque transmission. Common industries include cement manufacturing, mining, steel production, chemical processing, and power generation.

Belon Gear’s Expertise

At Belon Gear, we have more experience in designing and producing large diameter gears, including custom girth gears up to 12 meters in diameter. Our manufacturing capabilities include:

Advanced CNC gear cutting and hobbing up to DIN 6–7 precision

Segmented gear design for ease of transport and installation

Material selection optimized for durability: forged alloy steel, cast steel, or ductile iron

Heat treatment and surface hardening to increase wear resistance and service life

Our quality assurance process includes ultrasonic testing, magnetic particle inspection, and run out checks to ensure perfect tooth engagement and alignment.

Applications and Advantages

Girth gears produced by Belon Gear are used in:

Ball mills and SAG mills in mineral processing

Rotary kilns in cement and lime production

Rotary dryers and granulators in chemical and fertilizer industries

Key advantages of our girth gears include:

High torque transmission capability

Long operational life with minimal maintenance

Easy replacement of individual segments

Compatible with existing drive systems (pinion, gear reducer, etc.)

Why Choose Belon Gear?

What sets Belon Gear apart is our commitment to custom engineering, precision machining, and responsive service. From design consultation to final installation support, we work closely with plant engineers and OEMs to deliver gears that perform reliably even in the harshest operating environments.

Whether you need a replacement gear for an aging kiln or a brand new solution for a custom project, Belon Gear is your trusted partner in large diameter gear manufacturing.

Contact us today to learn more about how our girth gears can help improve the efficiency and reliability of your rotary equipment.

Post time: Jun-11-2025