Sun Gear in Planetary Gear Systems

Function, Structure, and Role in Power Transmission

A sun gear is a critical component in a planetary gear system, also known as an epicyclic gear train. Planetary gear systems are widely used in industrial machinery, automotive transmissions, robotics, and precision equipment due to their compact structure, high torque density, and efficient power transmission.

Understanding the function of the sun gear and its interaction with the planetary carrier, planetary carriers, and internal gear is essential for selecting and designing reliable gear solutions.

What Is a Sun Gear

The sun gear is the central gear in a planetary gear system. It is typically mounted on the input or output shaft and meshes directly with multiple planet gears that rotate around it.

As the sun gear rotates, it drives the planet gears, which are supported by the planetary carrier. These planet gears also mesh with the internal gear, forming a balanced and highly efficient transmission system.

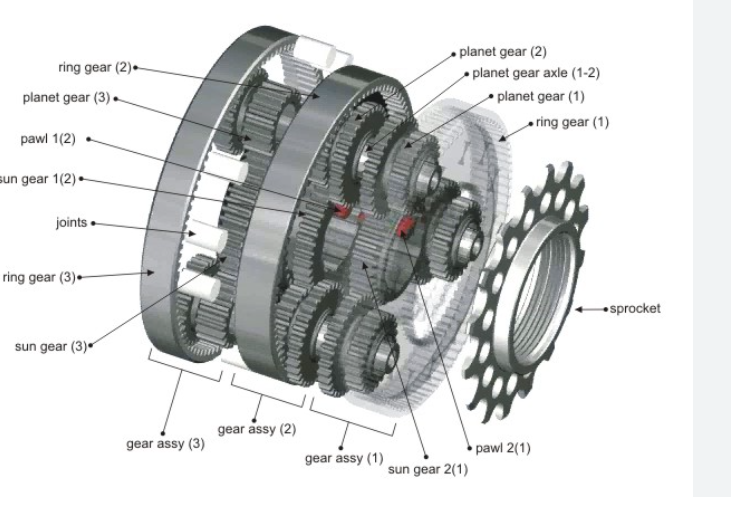

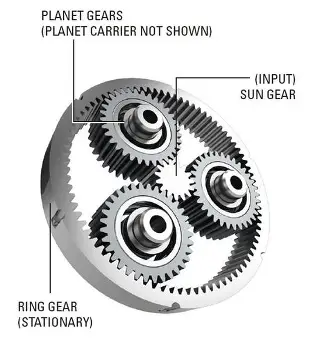

Main Components of a Planetary Gear System

A planetary gear system consists of four key elements:

Sun Gear

The sun gear is located at the center of the system and serves as the primary driving or driven gear.

Planet Gears

Multiple planet gears mesh with the sun gear and rotate around it. They distribute the load evenly across the system.

Planetary Carrier / Planetary Carriers

The planetary carrier holds the planet gears in position and allows them to rotate around the sun gear. In systems with multiple stages, planetary carriers are used to support different sets of planet gears.

Internal Gear

The internal gear, also called a ring gear, features internal teeth that mesh with the planet gears. It typically remains stationary or acts as an output component, depending on the transmission design.

How the Sun Gear Works with the Planetary Carrier and Internal Gear

In operation, the sun gear transmits power to the planet gears. The planet gears, mounted on the planetary carrier, rotate while simultaneously engaging with the internal gear. This configuration allows torque to be shared across multiple gear teeth, significantly increasing load capacity and reducing wear.

By fixing or driving different components—such as the sun gear, planetary carrier, or internal gear—engineers can achieve various gear ratios, speed reductions, or torque increases within a compact space.

Advantages of Sun Gear-Based Planetary Gear Systems

Planetary gear systems with a well-designed sun gear offer several advantages:

-

High torque transmission in a compact design

-

Even load distribution across multiple planet gears

-

High efficiency and smooth operation

-

Flexible gear ratio configurations

-

Improved durability and long service life

These benefits make sun gears essential in applications requiring high power density and reliability.

Typical Applications of Sun Gears

Sun gears are commonly used in:

-

Industrial gearboxes and speed reducers

-

Automotive automatic transmissions and hybrid systems

-

Robotics and automation equipment

-

Construction and mining machinery

-

Wind power and heavy-duty drive systems

In these applications, precision manufacturing of the sun gear, planetary carrier, and internal gear is critical to system performance.

Material and Manufacturing Considerations

Sun gears are typically manufactured from high-strength alloy steel or stainless steel to withstand high loads and repeated stress cycles. Advanced heat treatment processes such as carburizing and quenching are often applied to improve surface hardness and wear resistance.

Accurate tooth geometry, tight tolerances, and proper surface finishing ensure reliable meshing with the planet gears and internal gear.

Choosing the Right Sun Gear for Your Application

When selecting a sun gear, engineers should consider:

-

Required torque and speed

-

Gear ratio and system configuration

-

Load distribution across planetary carriers

-

Material and heat treatment requirements

-

Compatibility with the internal gear and planet gears

A properly engineered sun gear ensures stable operation and maximizes the efficiency of the entire planetary gear system.

The sun gear plays a central role in planetary gear systems, working together with the planetary carrier, planetary carriers, and internal gear to deliver compact, efficient, and high-torque power transmission solutions.

For industrial and mechanical applications where performance, durability, and space efficiency are critical, planetary gear systems with precision-engineered sun gears remain one of the most effective transmission solutions available.

Post time: Dec-22-2025