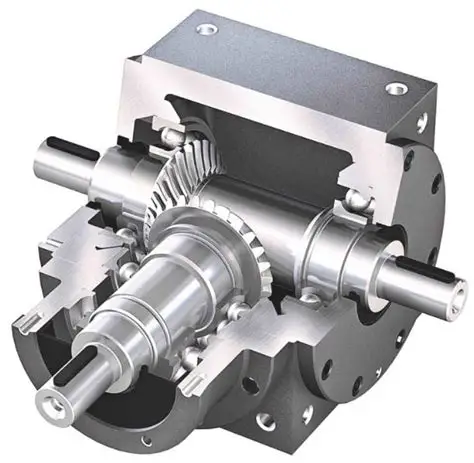

Belon Gear is proud to announce the successful completion and delivery of a customized gear solution for one of our long term, renowned gearbox customers based in Southeast Asia. The project involved the reverse engineering, precision manufacturing, and quality control of a matched ring gear and bevel gear set, designed to meet the customer’s specific performance and durability requirements in high load applications.

The client, a major player in the regional gearbox industry, approached us with detailed operational challenges, including tight dimensional tolerances, high torque transmission, and noise reduction. After an in depth technical discussion and analysis of the original components, our engineering team initiated the reverse engineering process. Leveraging 3D scanning, CAD modeling, and advanced materials evaluation, we were able to reproduce the complex geometry of the ring and bevel gear with high precision.

One of the key technical challenges was achieving the correct tooth contact pattern and surface hardness required for long term durability. To address this, we selected a high grade alloy steel, followed by optimized heat treatment to ensure core toughness and surface wear resistance. The manufacturing process involved CNC bevel gear cutting, grinding, and gear lapping to deliver exceptional gear meshing performance and reduced noise levels during operation.

Each gear set was subjected to rigorous quality control processes, including:

-

Gear tooth profile and lead inspection using Klingelnberg P series measuring machines

-

Magnetic particle testing for surface defects

-

Hardness and case depth verification after heat treatment

Our customer was impressed by both the speed of delivery and the technical accuracy of the final gear products. From prototype to final shipment, the entire process was completed in just under five weeks, allowing the client to reduce downtime and improve operational efficiency.

This successful project further strengthens our position as a reliable gear manufacturing partner in Southeast Asia, capable of delivering tailor made solutions for mission critical gearbox systems. At Belon Gear focusing on high precision OEM gears, shafts , Our OEM gears included straight bevel gears ,spiral bevel gears ,cylindrial gears ,worm gears ,spline shafts etc,we continue to invest in technology, talent, and testing systems to support our customers across diverse industries, including robotics, agriculture, marine, and industrial machinery.

We appreciate the trust our Southeast Asian partners place in us and look forward to many more collaborative successes in the region.

Post time: Aug-05-2025