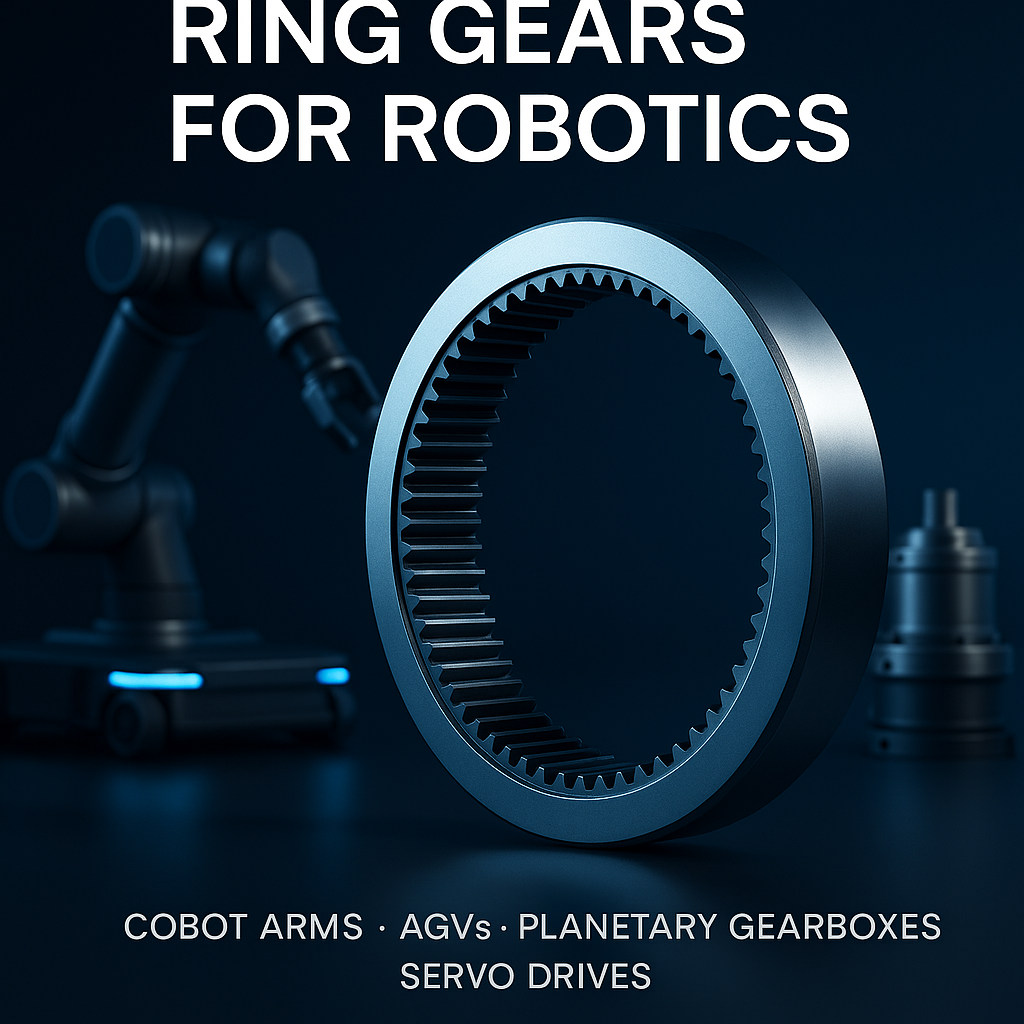

Planetary Ring Gears for Robotics, Cobot Arms, AGVs, Planetary Gearboxes, and Servo Drives

Planetary ring gears play a critical role in modern motion systems, particularly in industries where compact design, efficiency, and precision are essential. As robotics and automation continue to reshape manufacturing, logistics and mobility, planetary ring gears have become indispensable components in robotic arms, collaborative robots (cobots), automated guided vehicles (AGVs), planetary gearboxes, and servo drives. At Belon Gear, we specialize in designing and manufacturing planetary ring gears that deliver outstanding reliability and performance for these advanced applications.

In robotics precision is everything. Robotic arms and cobots require smooth, accurate and repeatable motion to perform tasks such as welding, material handling, or assembly. The planetary ring gear, working in combination with sun and planet gears, ensures high torque density while maintaining compact size. This allows robotic systems to achieve excellent power transmission efficiency with minimal backlash, supporting both speed and accuracy in highly dynamic operations.

For cobots, safety and reliability are particularly important. Planetary ring gears contribute to stable torque transmission, low noise levels, and optimized load distribution, which are critical for human-robot collaboration. By utilizing advanced materials, heat treatment, and fine machining, Belon Gear ensures that each ring gear offers long service life and minimal maintenance, even in demanding continuous operation environments.

Automated guided vehicles and autonomous mobile robots depend on planetary gear systems to deliver consistent performance in logistics, warehousing, and smart factories. The planetary ring gear provides durability and the ability to handle frequent start-stop cycles, heavy payloads, and constant directional changes. With precise tolerances and robust surface treatments, our gears help AGVs maintain efficiency and reliability across long duty cycles.

Planetary gearboxes and servo drives also rely heavily on planetary ring gears. In servo-driven systems, smooth torque transfer and high rigidity are essential for accurate positioning and responsive control. Belon Gear’s planetary ring gears are engineered to reduce vibration, enhance load-sharing, and achieve higher torque transmission capabilities within compact gearboxes. This makes them ideal for servo drives used in robotics, CNC machines, and automation lines.

At Belon Gear, quality is at the core of everything we produce. Each planetary ring gear undergoes strict dimensional inspection, hardness and material testing, tooth profile analysis, and surface contact checks. By adhering to international standards such as AGMA, ISO and DIN, we ensure that our customers receive gears that exceed expectations in both performance and durability.

As robotics and automation technologies continue to evolve, the demand for reliable, high performance gear components will only increase. Belon Gear is committed to supporting global customers with customized planetary ring gears that meet the exact requirements of robotic systems, cobots, AGVs, planetary gearboxes, and servo drives. With our expertise in precision gear manufacturing, we provide solutions that empower the future of intelligent automation.

Post time: Aug-19-2025