What Is a Pitch Circle in Gears?

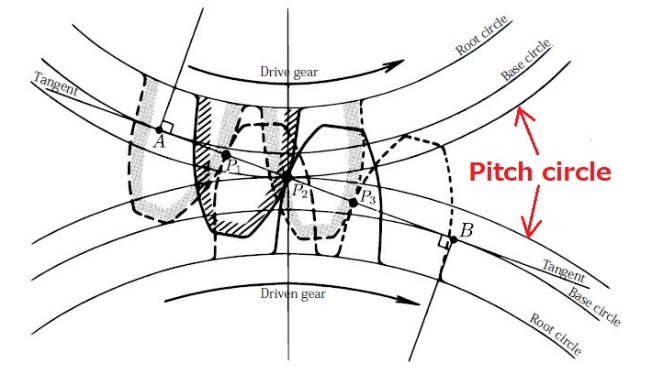

In gear engineering, the pitch circle also known as the reference circle is one of the most essential concepts for defining how two gears mesh and transmit motion. It serves as the imaginary circle that represents the effective contact point between mating gears, ensuring smooth and accurate power transmission.

Definition and Meaning

The pitch circle is an imaginary circle that rolls without slipping with the pitch circle of another gear in mesh. The diameter of this circle is known as the pitch diameter, and it determines the gear’s size, speed ratio, and center distance when paired with another gear.

It is at this circle that:

-

The tooth thickness equals the tooth space,

-

The velocity ratio between gears is constant,

-

And pure rolling motion occurs (no sliding).

Mathematically, the pitch diameter (Dp) is related to the module (m) and the number of teeth (z) by:

Dp = m × z

This equation makes the pitch circle a key reference for all gear design calculations.

Role and Importance of the Pitch Circle

The pitch circle defines the geometry and function of the entire gear. Its importance can be summarized as follows:

Determines Gear Ratio

The ratio of the pitch diameters between two gears gives the speed ratio of the system. For example, if Gear A has twice the pitch diameter of Gear B, Gear B will rotate twice as fast.

Controls Center Distance

The sum of the pitch circle radii of two meshing gears determines the center distance between their shafts—a critical factor in gearbox design and alignment.

Basis for Tooth Profile Design

The involute tooth profile is generated from the base circle, which is derived from the pitch circle. Therefore, it directly affects how smoothly and quietly the gears engage.

Ensures Smooth Power Transmission

When gears mesh at their pitch circles, they transmit motion with uniform angular velocity minimizing vibration, noise, and wear.

Pitch Circle in Gear Manufacturing

In practical production, the pitch circle cannot be physically measured since it is an imaginary reference. However, precision gear manufacturers like Belon Gear use advanced CNC gear measurement systems and 3D inspection to ensure all dimensions related to the pitch circle are precisely maintained. This guarantees accurate meshing performance across applications such as automotive gearboxes, industrial robots, and heavy duty machinery.

Post time: Oct-29-2025