-

Exploring Bevel Gear Applications

Bevel gears are a type of gear that have intersecting axes and teeth that are cut at an angle. They are used to transmit power between shafts that are not parallel to each other. The teeth of bevel gears can be straight, helical, or spiral, depending on the specific application. One of the key ad...Read more -

Deciphering the Direction of Bevel Gears

Bevel gears, with their angled teeth and circular shape, are indispensable components in various mechanical systems. Whether in transportation, manufacturing, or power generation, these gears facilitate motion transfer at different angles, enabling complex machinery to operate smoothly. However, ...Read more -

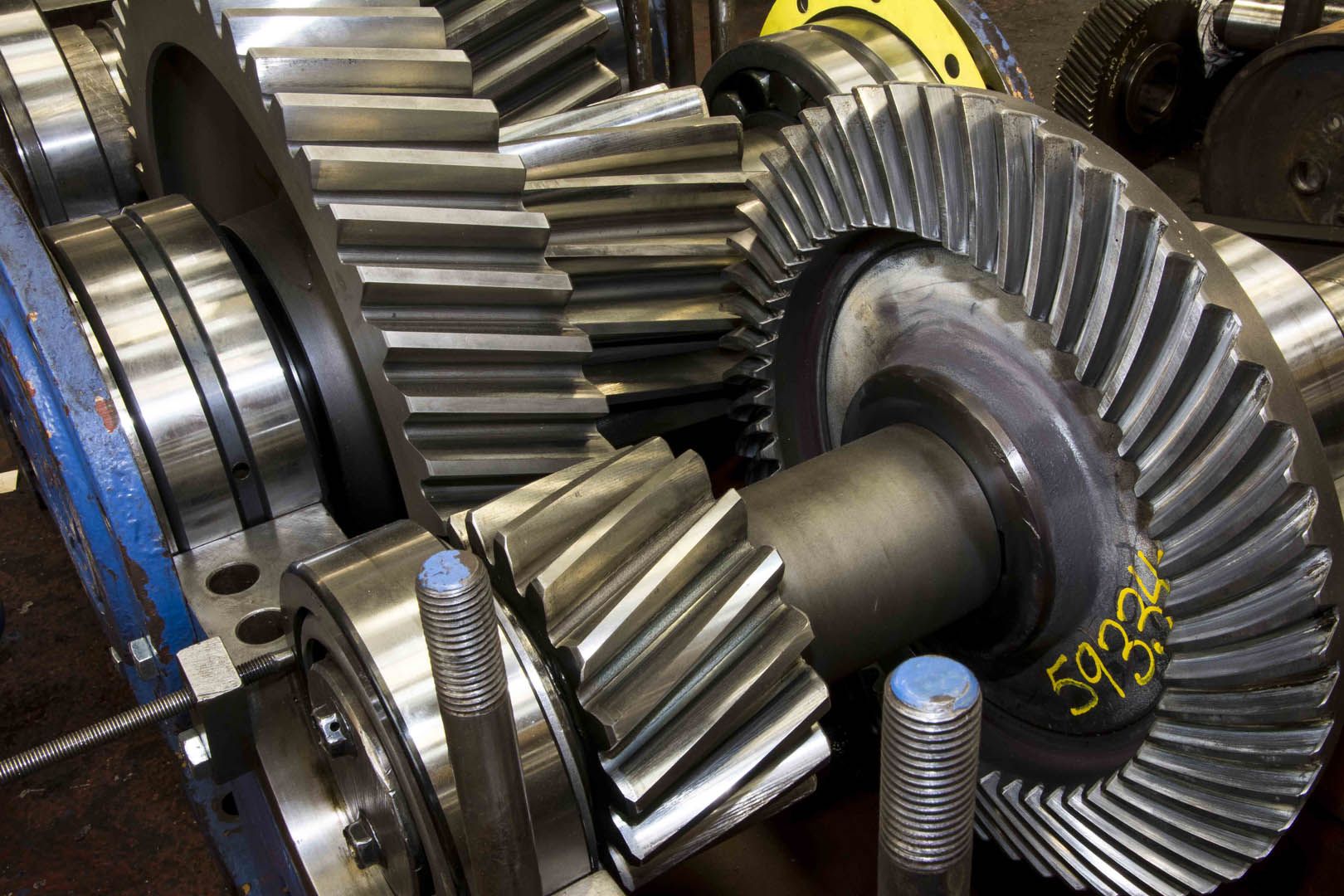

Bevel Gear Gearing for Heavy Equipment Industrial Machinery

Bevel gear units in heavy equipment play a vital role in the overall functionality and performance of these powerful machines. Bevel gears, including helical bevel gears and spiral bevel gears, are widely used in heavy equipment to transmit power and motion between shaft...Read more -

Exploring Virtual and Formative Bevel Gears

Angular bevel gears, crucial in machinery for directing motion and power transmission, have witnessed a transformative era with the integration of virtual and formative technologies. This synthesis has redefined traditional gear design and manufacturing processes. Virtual Angular Bevel Gea...Read more -

Enhancing Mining Efficiency with Helical Bevel Geared Motors

In the mining industry, the reliability and efficiency of machinery are paramount. Helical bevel-geared motors play a crucial role in achieving optimal performance, durability, and versatility in mining operations. Key Advantages: Robust Construction: Built to withstand harsh mining condit...Read more -

The Precision Art of Forging Straight Bevel Gears for Tractors

In the ever-evolving landscape of agriculture, the efficiency and reliability of farming machinery play a pivotal role in shaping the industry’s future. Tractors, the workhorses of modern farming, have undergone significant advancements to meet the increasing demands for productivity. Bevel...Read more -

What is a spiral bevel gear used for the final drive?

Spiral bevel gears are commonly used as final drives in mechanical systems, particularly in automotive and industrial applications. The final drive is the component that transfers power from the transmission to the wheels. Choosing spiral bevel gears as the final transmi...Read more -

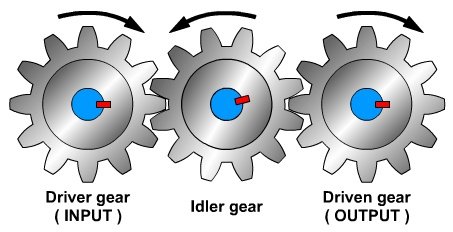

Exploring the Versatility and Applications of Planetary Gearboxes

Planetary gearboxes, also known as epicyclic gear systems, play a pivotal role in various mechanical applications due to their compact design, high efficiency, and versatility. This article delves into the applications of planetary gearboxes, shedding light on their diverse uses across different ...Read more -

Evolution of Hypoid Gears From Heavy-Duty Truck Axles to Advanced Motion Control Applications

Hypoid gears have come a long way since their introduction, playing an important role in the development of axial tip motion control applications in heavy-duty trucks. These high-performance gears have proven to be indispensable in many industries, improving efficiency, power transmission and dur...Read more -

What is the virtual number of teeth in a bevel gear ?

The virtual number of teeth in a bevel gear is a concept used to characterize the geometry of bevel gears. Unlike spur gears, which have a constant pitch diameter, bevel gears have varying pitch diameters along their teeth. The virtual number of teeth is an imaginary parameter that helps express ...Read more -

Can bevel gear replace worm gear?

The choice between using a worm gear or a bevel gear in a mechanical system can have a significant impact on its performance, efficiency, and overall cost. Both types of gears have their unique characteristics and strengths, so it is essential to understand the differences between them when decid...Read more -

Which material is best for helical and bevel gears ?

When it comes to choosing the right material for helical and bevel gears, several factors need to be considered to ensure optimal performance and longevity. Both types of gears play critical roles in various mechanical systems, and selecting the app...Read more