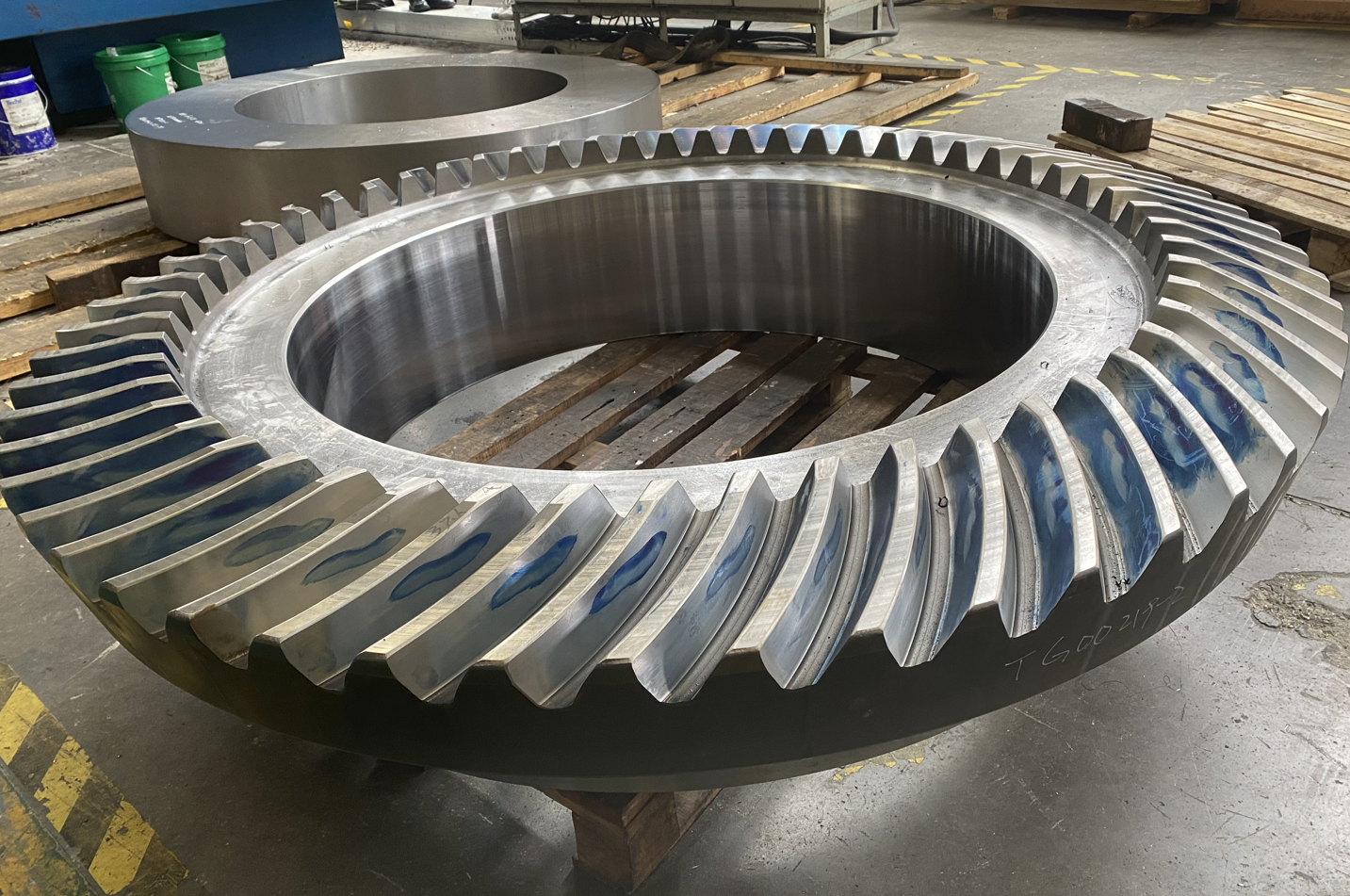

Spiral bevel gears are essential components in mechanical systems where torque must be transmitted between intersecting shafts, often at a 90 degree angle. With curved teeth and smooth meshing characteristics, they offer significant advantages in terms of efficiency, noise reduction, and load capacity. At Belon Gear, we specialize in the precision manufacturing of custom spiral bevel gears tailored for demanding industrial applications.

Unlike straight bevel gears spiral bevel gears feature helical teeth that engage gradually, resulting in smoother operation and quieter performance under load. This makes them ideal for heavy duty environments where vibration control and transmission accuracy are critical such as in mining equipment, construction machinery, marine propulsion systems, and industrial gearboxes.

Belon Gear offers spiral bevel gears in a wide range of sizes, materials, and precision classes. We manufacture both standard and custom-designed gear sets using advanced CNC machining and Klingelnberg bevel gear grinding technology to ensure accurate tooth geometry and consistent quality. Our spiral bevel gears are available in various configurations, including:

-

Ground or milled tooth profiles

-

Left hand and right-hand spiral angles

-

Single or paired gear sets

-

Customized center distances and shaft angles

We work with high grade alloy steels, stainless steels, and other durable materials, combined with heat treatment and surface hardening to ensure excellent wear resistance and long operational life, even under extreme loads and harsh environments.

In mining operations, spiral bevel gears are commonly used in crushers, conveyors, and heavy-duty reduction drives. Their ability to handle shock loads and transmit high torque without failure makes them a preferred solution over other gear types. Belon Gear provides complete engineering support, from design validation to prototyping and mass production, ensuring that each gear set meets your mechanical and dimensional requirements.

With a strong focus on quality control, Belon Gear uses advanced inspection equipment to verify gear accuracy, tooth contact, and surface finish. Our gear solutions are ISO compliant and trusted by clients worldwide for their performance and reliability.

For industrial applications where precision and power must come together, Belon Gear’s spiral bevel gears deliver unmatched efficiency and durability.

Post time: Jul-01-2025