Understanding the Helix Angle of Gears: Definition Importance and Applications

In gear engineering, one of the most critical parameters that affects performance, efficiency, and noise level is the helix angle. This concept is especially important in helical gears, which are widely used in automotive transmissions, industrial gearboxes, aerospace, robotics, and heavy machinery. Understanding what the helix angle is, how it influences gear behavior, and why it matters is essential for engineers and manufacturers aiming to optimize gear design.

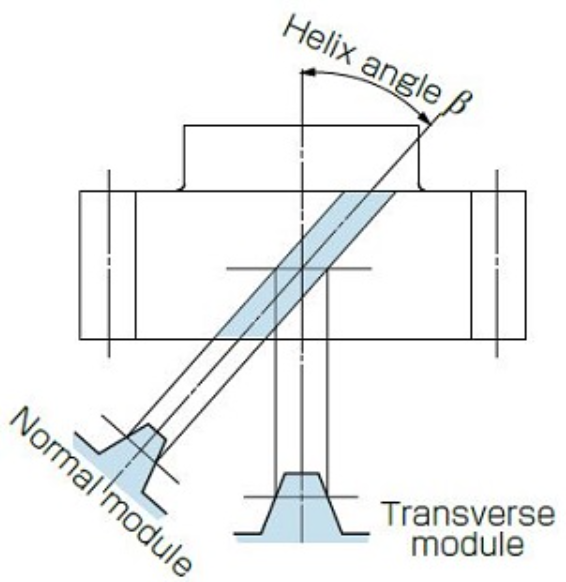

What is the Helix Angle?

The helix angle refers to the angle formed between the gear tooth and the gear’s axis of rotation. In helical gears, the teeth are not cut straight across the face of the gear, as in spur gears, but are set at an angle, creating a helix shape around the gear’s circumference. This angle can range from small degrees up to around 45°, depending on the application and performance requirements.

-

Smaller helix angles (e.g., 15°) result in smoother operation compared to spur gears but still maintain relatively straightforward manufacturing.

-

Larger helix angles (e.g., 30° or more) provide even smoother engagement and higher load-carrying capacity but generate greater axial thrust, which must be managed with bearings or thrust washers.

Importance of Helix Angle in Gear Design

The helix angle plays a central role in determining the operational characteristics of helical gears:

-

Smooth Power Transmission

Because of the angled teeth, gear engagement is gradual rather than instantaneous. This reduces shock loads, vibrations, and noise, making helical gears ideal for high-speed and high-power applications. -

Load Distribution

A larger helix angle increases the contact ratio, meaning more teeth are engaged at the same time. This distributes the load over multiple teeth, improving durability and load capacity. -

Axial Thrust

The downside of the helix angle is that it introduces axial forces along the gear’s shaft. The larger the helix angle, the higher the axial load, which requires stronger bearing arrangements. -

Efficiency vs. Strength Trade-off

While higher helix angles increase strength and smoothness, they may reduce efficiency slightly due to increased sliding friction. Designers must balance these factors based on the intended application.

Applications of Different Helix Angles

The selection of the helix angle depends on the type of machinery and performance needs:

-

Automotive Transmissions

Helical gears with helix angles around 20–30° are common in car gearboxes because they provide quiet, smooth operation and high torque transmission. -

Industrial Gearboxes

Larger helix angles are often used to increase load-carrying capacity for heavy-duty machinery such as conveyors, crushers, and cement mills. -

Robotics and Precision Equipment

Smaller helix angles or even crossed helical gear designs are chosen for compact, lightweight gearboxes requiring precise motion control. -

Aerospace Applications

Balanced helix angles are critical to reduce noise, vibration, and wear in high-speed turbine gearboxes.

Helix Angle vs. Pressure Angle

It is important not to confuse the helix angle with the pressure angle. The pressure angle relates to the force direction between meshing teeth, while the helix angle refers specifically to the angular orientation of the teeth. Both parameters must be considered together for optimal gear design.

Post time: Aug-21-2025