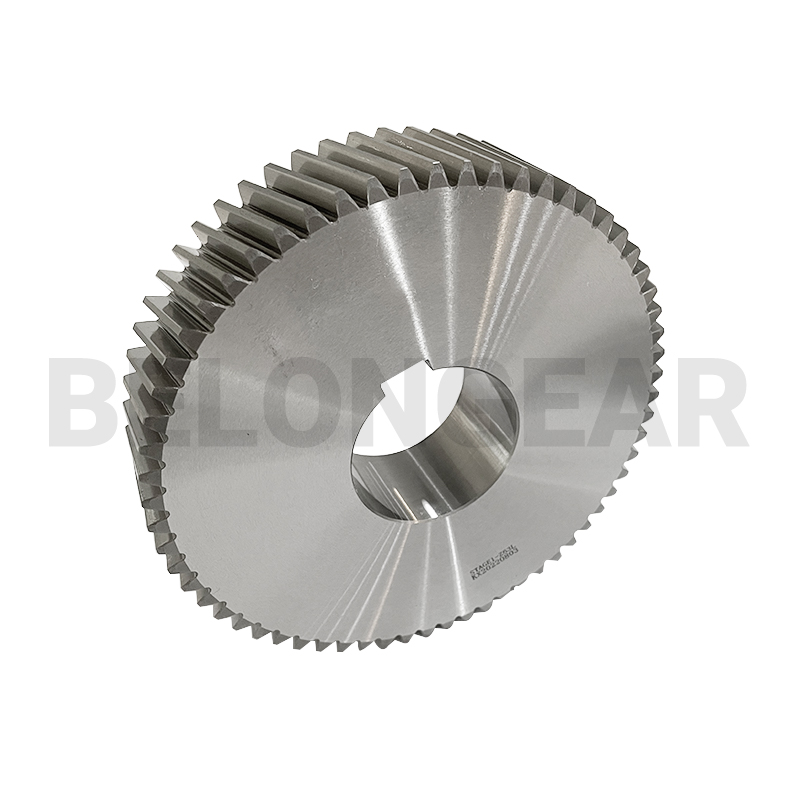

Helical Gear for Automotive Transmission

A helical gears is one of the most important components in an automotive transmission system, designed to transfer power smoothly and efficiently between rotating shafts. Unlike spur gears with straight teeth, helical gears have angled teeth that engage gradually, resulting in quieter operation, higher load capacity, and superior performance at high speeds. Their unique geometry allows for continuous contact between teeth, ensuring reduced vibration and enhanced torque transmission essential qualities for modern vehicles that demand both power and comfort.

In an automotive gearbox, helical gears are used in various stages to transmit power from the engine to the drive wheels. The helical design distributes loads across multiple teeth, improving durability and allowing the gearbox to handle higher torque with less noise. These gears are widely used in manual and automatic transmissions, as well as in hybrid and electric vehicle systems where smooth power transfer and energy efficiency are crucial.

Helical gears are typically made from alloy steel, carbon steel, or case hardened steel, depending on application requirements. The manufacturing process involves precision gear hobbing, shaving, grinding, and heat treatment to achieve the desired accuracy and hardness. The helix angle, pressure angle, and module are carefully calculated to meet specific automotive standards, ensuring perfect meshing and optimal power transmission.

Materials for Automotive Helical Gears

| Material Type | Typical Grade | Properties | Applications |

|---|---|---|---|

| Alloy Steel | 20CrMnTi, 18CrNiMo7-6 | High strength, excellent hardenability, good fatigue resistance | Automotive transmission gears |

| Carbon Steel | 1045, 1050, C45 | Moderate hardness, cost-effective, easy machining | Light load transmission systems |

| Case-Hardened Steel | SCM415, 8620 | Tough core with hard surface, ideal for high torque loads | Gearbox and differential components |

| Stainless Steel | SUS420, 17-4PH | Corrosion resistance, stable performance in harsh conditions | Special automotive or marine use |

| Nitrided Steel | 42CrMo4 | Excellent wear resistance and dimensional stability | High-speed precision transmission |

Advantages of Helical Gears in Automotive Applications

Smooth and Silent Operation – The gradual engagement of teeth reduces impact noise and vibration.

High Load Capacity – Multiple teeth in contact allow for better load distribution and higher torque transmission.

Improved Efficiency – Helical gears minimize energy loss, enhancing vehicle performance and fuel economy.

Durability and Reliability – Advanced materials and heat treatment processes extend service life under high speed and high-load conditions.

Belon Gear – Your Reliable Helical Gear Manufacturer

At Belon Gear, we specialize in producing customized helical gears for automotive transmissions with precision and consistency. Our production facilities are equipped with advanced CNC gear hobbing, grinding, and inspection machines to ensure the highest accuracy and quality. Every gear undergoes strict quality control, including noise testing and surface contact analysis, to guarantee excellent performance in automotive powertrains.

Helical gear automotive gears

Post time: Nov-05-2025