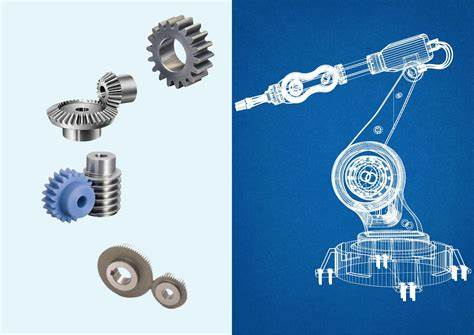

Bevel Gears and Gears for Robotics: Precision Motion for Modern Automation

In today’s rapidly advancing automation industry, precision gears are essential for achieving accurate motion control, torque transfer, and system reliability. Among the most widely used components in robotic and industrial drive systems are bevel gears and other gears for robotics, each offering specific advantages based on the design application.

What Are Bevel Gears?

Bevel gears are conically shaped gears designed to transmit motion between intersecting shafts, most commonly at a 90 degree angle. Their angled tooth design allows for smooth torque transfer with minimal backlash. Bevel gears are used in robotic arms, gearboxes, and mobile drive systems where angular motion is needed. Variants include straight bevel spiral bevel gear and hypoid bevel gears, each suited for different load capacities and noise requirements.

Straight bevel gears are simple and cost effective, best for lower speed applications.

Spiral bevel gears provide quieter and smoother motion, ideal for high performance robotics.

Hypoid gears offer offset shaft capability with increased torque.

Gears for Robotics: Types and Applications

In addition to bevel gears, robotics systems often incorporate several other gear types, depending on the application:

Spur gears – used for straightforward, high precision motion between parallel shafts.

Worm gears – offer high reduction ratios and self locking properties, suitable for robotic lifts and arms.

Planetary gears – ideal for compact, high torque setups, commonly used in servo motors and AGVs.

Helical gears – known for quieter, smoother operation, useful in robotic conveyor systems.

Each of these robotic gear solutions plays a critical role in improving motion accuracy, load handling, and system compactness.

Custom Gear Solutions for Robotics and Automation

We specialize in manufacturing robotic gears and bevel gear solutions tailored to modern automation requirements. Whether you need high strength alloy materials, precision machining, or surface treated components, we deliver gears that meet your performance, durability, and efficiency standards.

Contact us today to learn more about our gears for robotics and how our bevel gear solutions can power your next generation robotic system.

Post time: May-07-2025