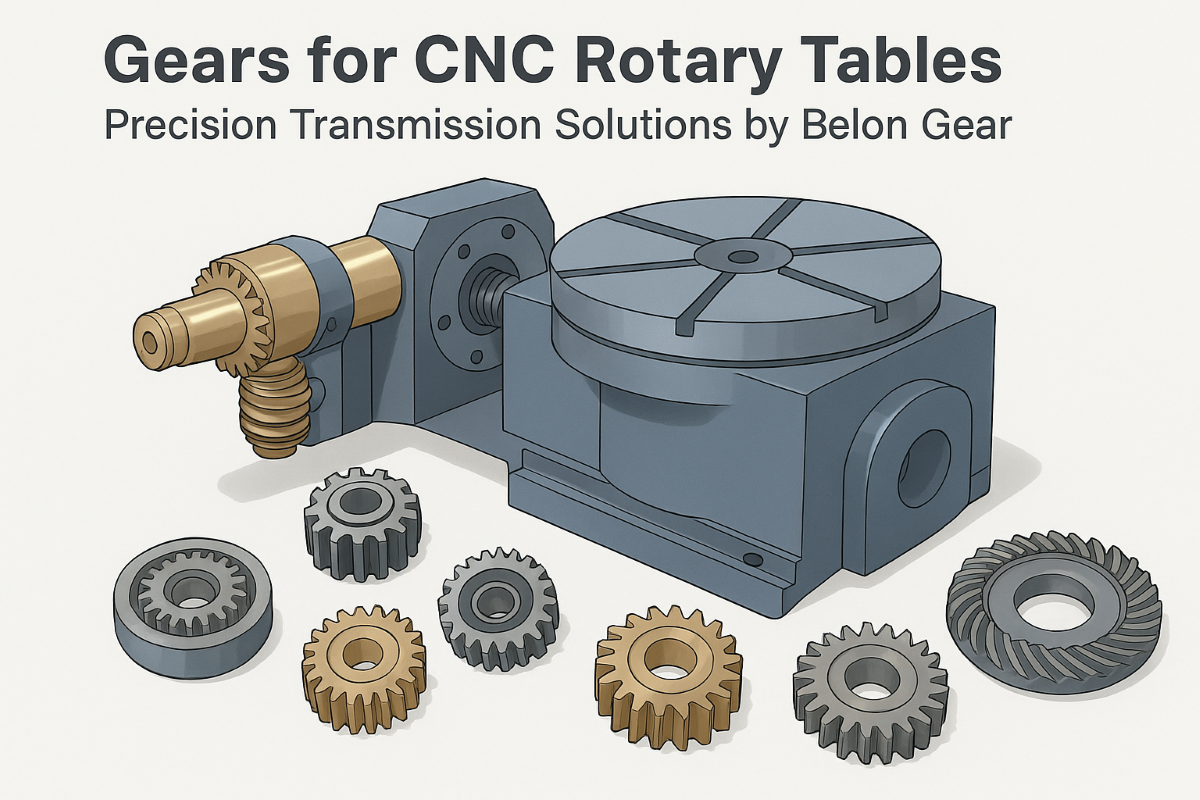

In the world of precision machining, CNC rotary tables play an essential role in enabling accurate indexing, continuous rotation, and multi-axis machining. Whether used in vertical machining centers, horizontal machining centers, 5 axis systems, or high precision positioning equipment, rotary tables rely heavily on advanced mechanical transmission components. Among these components, gears are the core elements that determine accuracy, rigidity, torque capacity, speed performance, and long-term stability.

As a global supplier of precision gear solutions, Belon Gear provides a complete range of custom engineered gears specifically designed for rotary table manufacturers, CNC machine builders, automation companies, and high precision positioning system suppliers. Our gears are manufactured with strict tolerances, optimized tooth profiles, and durability designed for heavy loads and long service life.

This article provides a comprehensive overview of the gears most commonly used in rotary tables, how each type works, and the specific advantages Belon Gear offers to the industry.

1. Worm Gear and Worm Shaft — The Traditional Core Powertrain

Worm gears sets have been the most widely used transmission structure in rotary tables. They remain highly popular, especially for medium-precision indexing tables, due to their unique mechanical advantages.

How They Work

A worm shaft drives a worm wheel (a type of helical gear with curved tooth engagement). Due to the sliding contact between the worm threads and the wheel teeth, the system achieves a high reduction ratio in a single stage.

Key Advantages

- High reduction ratio (i=1:40 ~ 1:120)

-

Self-locking ability, improving stability and safety

-

Smooth operation

-

Compact design

Applications

-

Standard CNC rotary tables

-

4 axis indexing tables

-

Heavy duty positioning mechanisms

Belon Gear Capabilities

Belon Gear manufactures worm wheels and worm shafts with:

-

Precision classes up to DIN 6

-

Bronze, alloy steel, and carburized materials

-

Grinding and lapping options for smoothness and durability

-

Custom profiles optimized for torque capacity and heat reduction

Our worm gear sets are engineered to minimize wear and maintain accuracy even under continuous machining cycles.

2. Planetary Gear Sets — High-Precision, High-Torque Power Transmission

Modern CNC rotary tables—especially high-speed models—frequently adopt planetary gear reducers combined with servo motors.

Why Planetary Gears Are Popular

Planetary gears provide:

-

High torque density

-

Extremely high transmission efficiency

-

Very low backlash (can reach < 3 arcmin)

-

Excellent concentricity and load distribution

In high precision 4-axis and 5-axis rotary tables, a planetary stage is often used before a direct-drive system or heavy-duty main shaft.

Belon Gear’s Strength in Planetary Systems

Belon Gear produces precision planetary gear components including:

-

Sun gears

-

Ring gears

-

Integrated carriers

Capabilities include:

-

Modules from m0.5 to m12

-

Tooth profile modifications for noise reduction

-

Heat treated alloy steels for long-term fatigue resistance

-

Ultra low backlash precision grinding

Our gears are widely used in servo rotary tables, robotic arms, and automated positioning systems.

3. Spiral Bevel Gears and Zerol Bevel Gears — Essential for 90° Power Transfer

Rotary tables often require an L-shaped (90 degree) transmission layout, especially when mounted directly to machine tools. This is where spiral bevel gears and Zerol bevel gears become essential.

Why Bevel Gears Are Used

-

Change direction of power transmission

-

Provide high torque capacity

-

Offer smooth and quiet operation

-

Support high-speed servo motor input

Spiral vs Zerol Bevel Gears

-

Spiral Bevel Gear: Curved teeth, smooth meshing, ideal for high speed and heavy loads

-

Zerol Bevel Gear: Zero degree spiral angle, hybrid between spiral and straight bevel; lower noise, more stable under precise indexing conditions

Belon Gear Advantages

Belon Gear specializes in bevel gear production using:

-

Gleason and Klingelnberg cutting systems

-

Grinding accuracy up to DIN 5

-

Modules from m0.5 to m35

-

Diameter range up to 1600 mm+

These gears are widely used in:

-

C-axis assemblies

-

High-torque indexers

-

Five-axis machining heads

4. Spur and Helical Gears — Auxiliary Transmission Components

While the main rotation usually relies on worm or planetary systems, spur and helical gears also play essential roles.

Gear Types Used in Rotary Tables

| Gear Type | Position Used | Main Function |

|---|---|---|

| Worm Gear & Worm Shaft | Main drive | Large reduction ratio, self-locking, precise positioning |

| Planetary Gear Reducer | Between motor and spindle | High torque, high-precision speed reduction |

| Helical Bevel / Zerol Bevel Gear | Direction-change transmission | 90° power transfer, high precision, low noise |

| Spur / Helical gears | Auxiliary drive, braking mechanism | Power transmission or clamping system |

| Harmonic Gear Drive | High-end rotary tables | Micron-level positioning, ultra-high precision |

Typical Uses

-

Internal transmission between motor and clamping system

-

Brake mechanism actuation

-

Encoder synchronization

-

Secondary reduction stages

Why They Matter

Even though these gears are not always the primary drive system, their quality directly impacts:

-

Backlash stability

-

Repeatability

-

Brake performance

-

Noise levels

Belon Gear produces spur and helical gears with:

-

Profile grinding

-

Carbide material options

-

Internal/external gear capability

-

Precision tooth modifications for load balancing

5. Harmonic Gears — Ultra-High Precision for Semiconductor-Grade Rotary Tables

In ultra precision rotary tables used for semiconductor processing, laser machining, optical alignment, or metrology systems, harmonic drive gears may be used.

Benefits

-

Near zero backlash (<1 arcsec)

-

Extremely high positioning accuracy

-

Compact, lightweight design

-

High reduction ratios

Where They’re Used

-

Micro-indexing platforms

-

High-precision wafer handling equipment

-

Multi-axis optical rotary stages

Belon Gear supplies flex-spline compatible gear teeth finishing and custom harmonic components.

Why Leading Manufacturers Choose Belon Gear for Rotary Table Gear Solutions

1. Ultra-High Precision Manufacturing

Belon Gear delivers tolerances aligned with:

-

DIN 5–7 for bevel gears

-

DIN 4–6 for cylindrical gears

-

Precision grinding for low-noise performance

2. Full Material Traceability

Materials include:

-

20CrMnTi

-

8620

-

18CrNiMo7-6

-

Brass, bronze (for worm wheels)

Each batch is fully traceable.

3. Gear Reverse Engineering for OEM Replacement

Belon Gear also supports customers who require:

-

Reverse design based on worn gears

-

Material upgrades

-

Hardness optimization

-

Backlash improvement

4. Customized Solutions for Every Type of Rotary Table

Including:

-

Heavy-duty indexing rotary tables

-

High-speed machining rotary tables

-

DD motor rotary tables

-

4-axis and 5-axis CNC rotary systems

-

Precision optical rotary stages

-

Automated positioning turntables

5. Consistent Quality, Global Delivery

Belon Gear supplies gear sets to clients across North America, Europe, South America, and Asia, supporting machine builders and industrial automation companies with reliable long-term gear solutions.

Conclusion

CNC rotary tables rely heavily on precision-engineered gears to deliver accurate, stable, and reliable rotational motion. Whether the system uses a traditional worm gear drive, a high-torque planetary gear reducer, a spiral bevel transmission, or advanced harmonic gearing, the quality of each gear directly determines the performance of the rotary table.

With advanced manufacturing capabilities, strict quality control, and deep expertise in industrial gear engineering, Belon Gear continues to support global customers with custom-designed gear solutions optimized for rotary tables and high-precision transmission applications.

If your project requires reliable, high-quality gear components for a rotary table, Belon Gear is ready to support you from design to delivery.

Post time: Nov-24-2025