Gear teeth are the fundamental elements that enable power transmission in mechanical systems. The shape, size, and arrangement of gear teeth determine how efficiently gears mesh, how much load they can carry, and how smooth the operation will be. Over the years, engineers have developed several gear teeth types to meet diverse industrial needs, from high precision robotics to heavy duty mining equipment. Understanding these different types is essential for selecting the right gear for any application.

One of the most common gear teeth types is the straight or spur gear tooth. This design features teeth that are cut parallel to the gear’s axis, allowing simple and efficient transmission of motion between parallel shafts. Spur gear teeth are easy to manufacture and cost effective, but they generate higher noise levels and vibration at high speeds. They are best suited for moderate speed applications where simplicity and strength are more important than noise reduction.

Helical gear teeth are cut at an angle to the axis of rotation. This angled design allows for gradual engagement of the teeth, which reduces noise and vibration compared to spur gears. Helical gear teeth also enable higher load capacity and smoother motion. Because of these advantages, helical gears are widely used in automotive transmissions, conveyors, and heavy machinery. They can transmit motion between both parallel and crossed shafts, offering more flexibility than spur gear teeth.

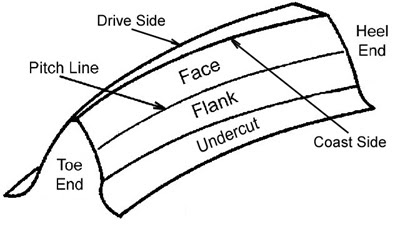

Bevel gears teeth are designed for gears that transmit motion between intersecting shafts, often at a right angle. The teeth can be straight, spiral, or zerol (curved but without angle). Straight bevel gears teeth work like spur gears and are simpler to manufacture, but they are noisier. Spiral bevel gear teeth, on the other hand, provide smoother engagement and quieter operation, making them suitable for high speed or high load applications such as in automotive differentials and aerospace gearboxes.

Worm gears teeth represent another unique design, where one gear resembles a screw meshing with a worm wheel. The tooth contact is sliding rather than rolling, which results in high reduction ratios and the ability to transmit motion at right angles. Worm gear teeth are excellent for applications requiring compactness and self locking capability, such as elevators, conveyor systems, and tuning mechanisms. However, their efficiency is lower compared to other gear teeth types due to greater friction.

Herringbone and double helical gears teeth are advanced versions of helical gears. Their design features two sets of helical teeth cut in opposite directions, which cancel out axial thrust. This makes them ideal for heavy machinery and marine applications where high power transmission is required without side thrust forces. Herringbone gear teeth also operate smoothly and quietly, though their manufacturing complexity makes them more costly.

Belon Gear Application Machinery Classification

| Functional Classification | Machinery Type | Core Function of Gear | Typical Gear Type Used |

| Power Transmission and Distribution | Gearbox / Reducer / Transmission | Change output speed and torque, or distribute power to different axes. | Spur, Helical, Bevel, Worm Gear |

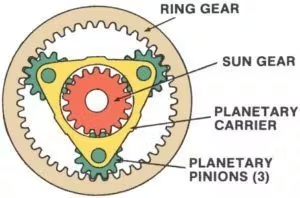

| Agricultural Field Operations | Agricultural Machinery (Tractors, Harvesters, Cultivators) | Provide high torque output in harsh field conditions, split power flow, and change transmission direction. | Spiral Bevel, Planetary, Spur |

| Change of Motion Direction | Differential | Transmit power at a right angle (or specific angle) and allow the two output axes to rotate at different speeds. | Bevel, Spiral Bevel |

| High Precision Positioning and Control | Robotics / Automation | Precise transmission of motion, control of joint angles, and repeatable positioning. | Planetary, Harmonic Drive, Cycloidal Gear |

| Heavy Load and Engineering Machinery | Construction / Mining Equipment | Provide large torque output and durability in high-load and harsh environments. | Planetary, Large Helical, Spur Gear |

| Aerospace and High Speed Applications | Aircraft Engines / Turbines | Efficient and smooth power transmission at extremely high speeds, requiring lightweight and high precision. | High precision Helical, Bevel Spur |

| Lifting and Traction | Cranes / Hoists | Provide large reduction ratios and locking capability for lifting and suspending heavy objects. | Worm, Spur Gear |

In addition to these common types, engineers often modify tooth geometry to improve performance. For example, profile shifting and tooth crowning help reduce edge contact and improve load distribution. In high precision fields like robotics and aerospace, minimizing backlash through special tooth design ensures accuracy and reliability.

The selection of gear teeth type depends on multiple factors, including load requirements, operating speed, desired efficiency, noise limitations, and manufacturing cost. For example, spur gear teeth are sufficient for simple machines and moderate loads, while helical or spiral bevel gear teeth are necessary for quieter and more efficient high speed systems. Worm gear teeth are chosen for compact, high reduction applications, and herringbone teeth are selected when stability and balance are critical.

In conclusion, gear teeth types represent the backbone of mechanical engineering, providing tailored solutions for different motion and power transmission challenges. Belon gears from the simplicity of spur teeth to the sophistication of spiral bevel or herringbone teeth, each design has unique advantages that serve industries ranging from automotive and aerospace to robotics and heavy equipment. As technology advances, further refinements in gear tooth geometry, materials, and manufacturing techniques will continue to enhance the performance, efficiency, and durability of gears across countless applications.

Post time: Sep-02-2025