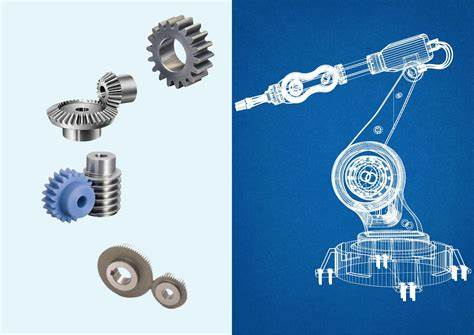

Belon Gear a trusted name in high precision gear manufacturing recently completed a successful project delivering custom bevel gears for a leading European robotics company. This achievement not only highlights Belon Gear’s engineering expertise but also demonstrates the company’s commitment to supporting innovation in the global robotics industry.

The client, a top tier robotics manufacturer known for its cutting edge automation systems, faced a complex challenge in developing a new robotic joint system. The project required compact, durable, and low noise bevel gears capable of withstanding high speed operation and long service cycles without failure. Belon Gear’s experienced engineering team collaborated closely with the client’s R&D department to design and manufacture a customized bevel gear solution that exceeded expectations.

Using advanced design software and 5 axis CNC machining, Belon Gear developed precision ground spiral bevel gears with a customized tooth profile and high surface finish. The gears were manufactured to DIN 7–9 class tolerances, ensuring excellent meshing, minimal backlash, and superior performance under load. To further enhance durability, each gear underwent a strict heat treatment process and surface hardening to meet the customer’s wear resistance requirements.

From initial technical consultation to final delivery, the entire project was completed in record time. Belon Gear’s streamlined production workflow and efficient supply chain allowed for rapid prototyping, quality validation, and mass production within a matter of weeks. The result: a 15% cost reduction and a 30% improvement in lead time compared to previous suppliers.

Custom Gear Solutions for Robotics

The successful execution of this project has helped the European client accelerate the launch of its next generation robotic systems. Moreover, the use of Belon’s custom bevel gears contributed to quieter and more reliable joint movements, directly enhancing the end user experience.

At Belon Gear, we understand that every robotics application has its unique mechanical demands. That’s why we offer full customization, including module sizes from M0.5 to M15, various materials (alloy steel, stainless steel, carbon steel), and optional finishes like black oxide or anti corrosion coating. Whether for humanoid robots, autonomous vehicles, or factory automation systems, our gear solutions are tailored for performance, reliability, and innovation.

This success story strengthens Belon Gear’s reputation as a trusted partner for precision gear solutions in Europe and beyond. We continue to invest in advanced manufacturing technologies, gear metrology, and global logistics to better serve our international customers.

If your robotics project demands precision, durability, and speed partner with Belon Gear. Together, we engineer the future.

Post time: Jul-21-2025