The rise of unmanned aerial vehicles (UAVs) has expanded beyond surveillance and reconnaissance into logistics, transportation, and defense. Among these, heavy payload unmanned helicopters have gained significant attention due to their ability to carry large loads, operate in difficult environments, and perform missions where traditional helicopters or ground vehicles may face limitations. At the core of these high performance machines lies a critical component: the bevel gear.

The Role of Bevel Gears in Helicopter Transmission

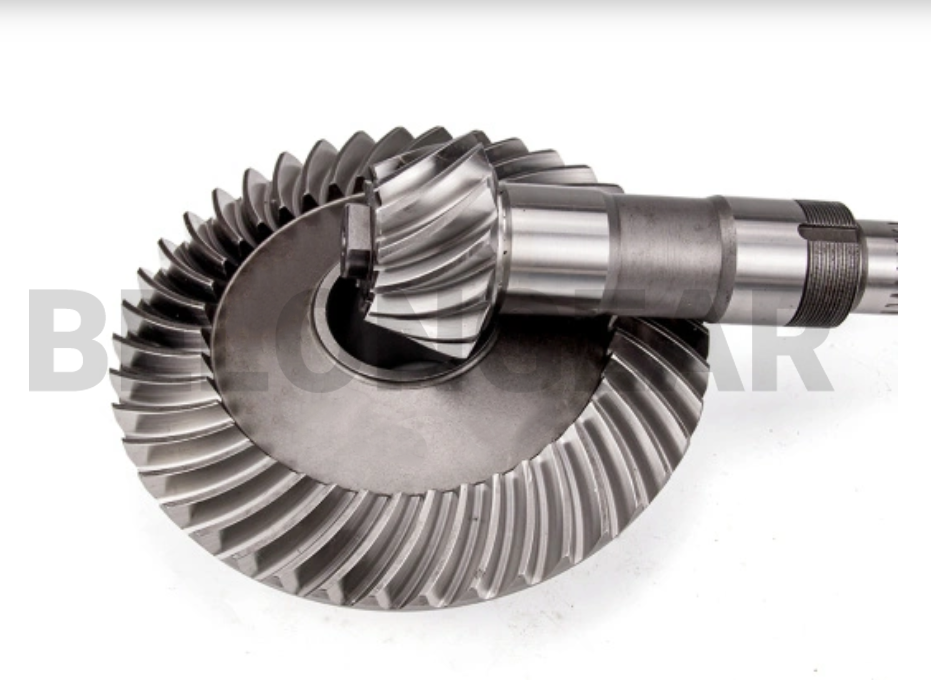

Bevel gears are specially designed gears that transmit power between shafts intersecting at an angle, most commonly 90 degrees. In helicopters, bevel gears play a central role in the gearbox and rotor drive systems, ensuring smooth and efficient transfer of torque from the engine to the rotor blades. For heavy payload unmanned helicopters, this transmission must withstand extreme loads while maintaining stability, precision, and reliability.

Unlike smaller UAVs, which may use lighter gear systems, heavy payload helicopters require Spiral bevel gears made from aerospace grade steel or alloy. Their curved tooth design allows gradual meshing, reducing vibration and noise while enabling high torque capacity an essential feature for carrying large cargo or equipment in challenging missions.

Engineering Demands of Heavy Payload UAV Helicopters

Operating an unmanned helicopter with a heavy payload introduces unique engineering challenges. The gears must handle:

High Load Stress – The gearbox experiences tremendous forces as it transfers engine power to lift heavy cargo. Bevel gears must be designed with optimized tooth geometry to avoid premature wear.

Precision and Balance – UAVs require precise flight stability. Any inconsistency in gear performance can lead to vibration, noise, and reduced operational control.

Durability in Harsh Environments – Heavy payload UAVs are often deployed in defense, rescue, or industrial operations where dust, moisture, and temperature fluctuations are present. Bevel gears must be corrosion resistant and heat treated for strength.

Lightweight but Strong Materials – Aerospace applications demand reduced weight without compromising performance. Alloy steel with advanced heat treatment and surface finishing provides an ideal balance.

Spiral Bevel Gears for UAVs Precision Transmission for Aerial Performance

Applications of Bevel Gears in Unmanned Helicopters

Bevel gears in heavy payload UAV helicopters support a wide range of applications:

Military Logistics: Transporting supplies, equipment, or weapons in areas inaccessible by manned aircraft.

Emergency Response: Delivering medical supplies, food, or rescue equipment during disasters.

Industrial Use: Lifting and carrying tools, materials, or monitoring systems for energy, mining, and infrastructure projects.

Surveillance and Defense: Supporting advanced sensors, communication systems, and defense payloads.

In each of these cases, the reliability of bevel gears ensures mission success and operational safety.

Belon Gear’s Aerospace Manufacturing Expertise

Producing bevel gears for aerospace UAVs requires advanced machining and strict quality control. At Belon Gear, we specialize in spiral bevel gears for aerospace and defense industries, combining Gleason technology, CNC machining, and precision grinding to achieve the highest accuracy standards (such as AGMA 12 or DIN 6). Our gears undergo hardness testing, tooth profile inspections, and non destructive examinations to guarantee exceptional reliability.

By integrating premium alloy steel, advanced heat treatment, and optimized tooth geometry, Belon Gear ensures every bevel gear delivers outstanding performance under extreme heavy payload conditions.

The success of heavy payload unmanned helicopters depends greatly on the strength and reliability of their transmission systems. Belon Gear’s bevel gears, particularly spiral bevel gears, provide the essential link between engine power and rotor performance, ensuring stability, efficiency, and durability. As UAV technology continues to expand into defense, logistics, and industrial applications, the demand for custom engineered aerospace bevel gears from Belon Gear will only increase.

By combining advanced materials, precise engineering, and strict quality standards, Belon Gear continues to power the next generation of unmanned helicopters, enabling them to lift heavier payloads and accomplish critical missions with confidence.

Post time: Sep-03-2025