Production Process

Inspection

We equipped full sets of inspection equipment for kinds of cylindrical gears like hexagon ,Zeiss 0.9mm ,Kinberg CMM, Klingberg CMM , Klingberg P100/p65/p26 GEAR MEASURING CENTER ,Gleason 1500GMM ,Germany Marr roughness meter ,Roughness Meter Profiler ,Projector ,Length Measuring Instrument etc. , Klingberg

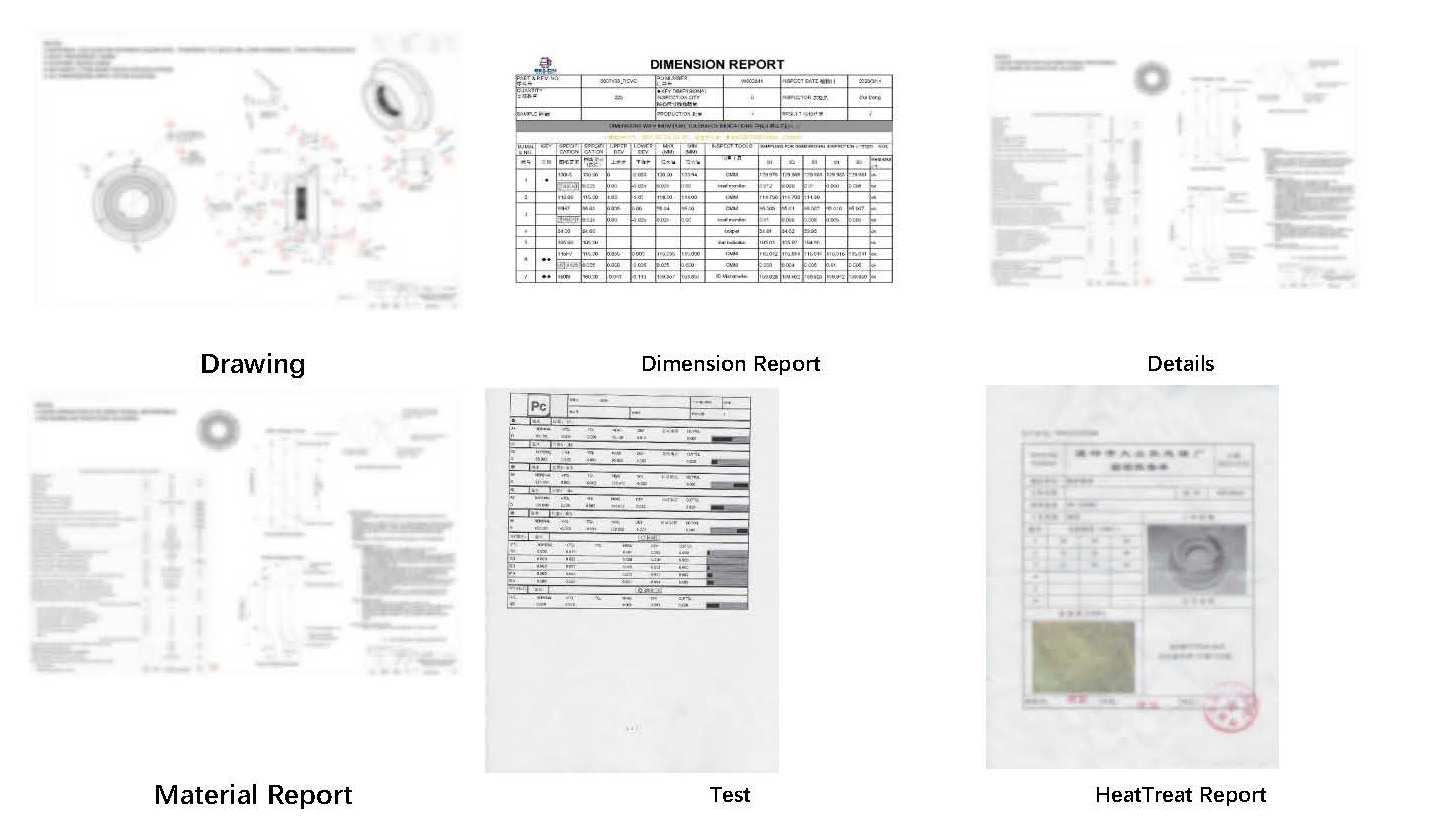

Reports

Before every shipping ,we will provide below these reports to customer to check details to make sure all are clear understood and good to ship .

1) Bubble drawing

2) Dimension report

3) Heat treat report before heat treat

4) Heat treat report after heat treat

5) Material report

6) Accuracy report

7) Pictures and all testing videos like runout , Cylindricity etc

8) Other testing reports per customers’ requirement like flaw detection report

Packages

Our video show

Write your message here and send it to us