Why every lapping bevel gear needs meshing test before shipping ?

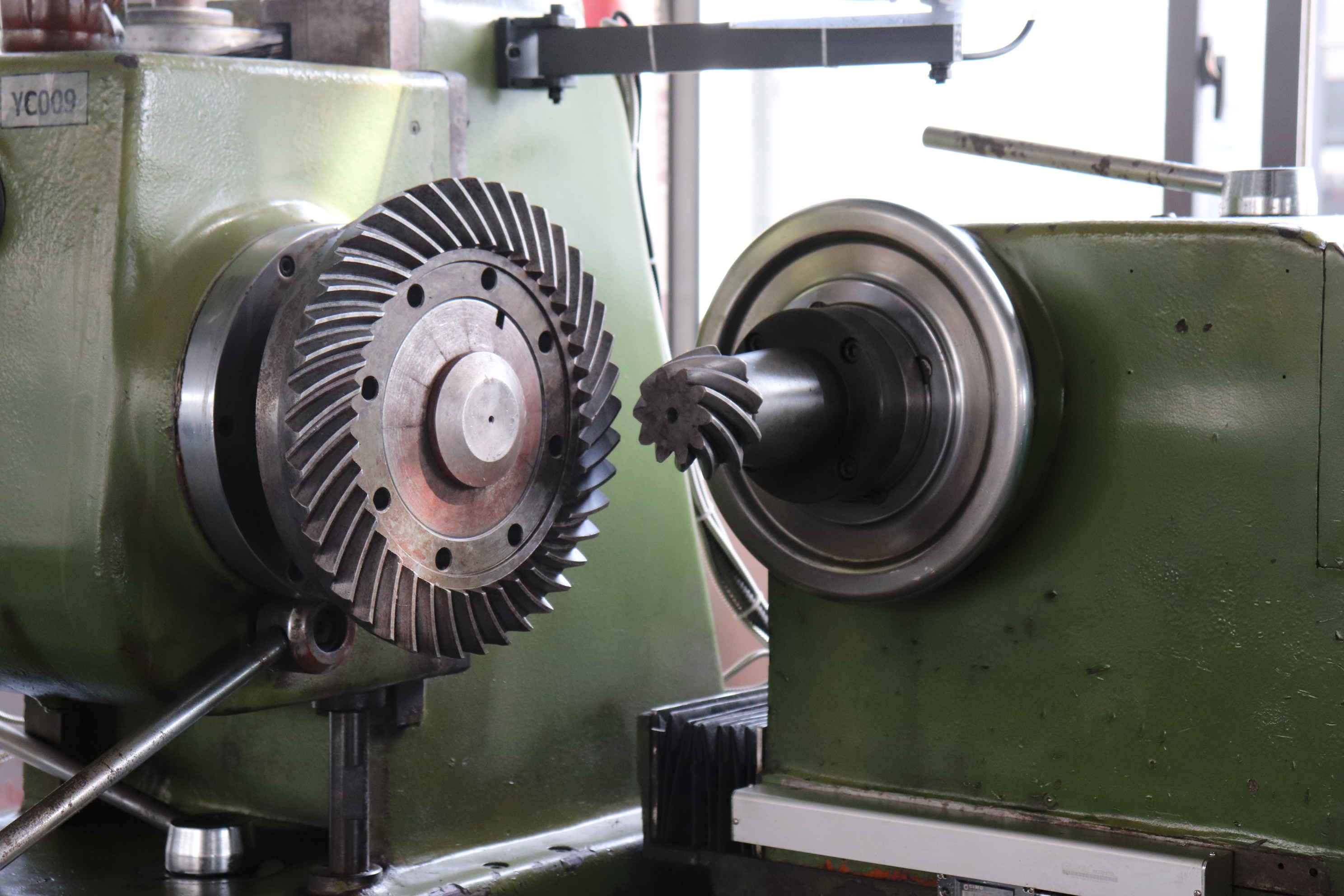

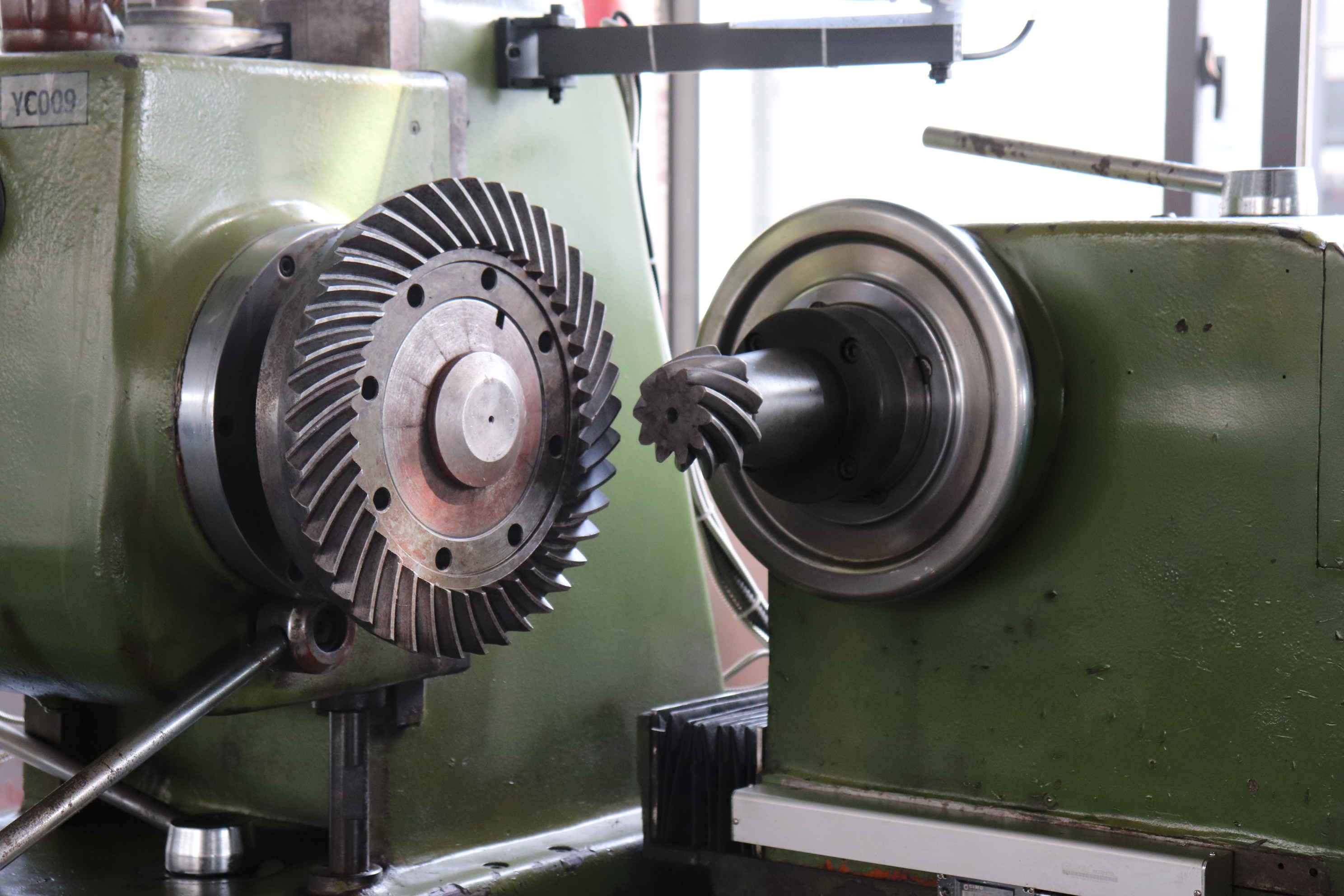

Before shipping ,we will do meshing test which was very important ,which is in order to test center distance ,backlash ,noise checking etc .It’s a kind of Simulate installation .As long as the meshing test was good ,the parts could be well assembled into the gearboxes.

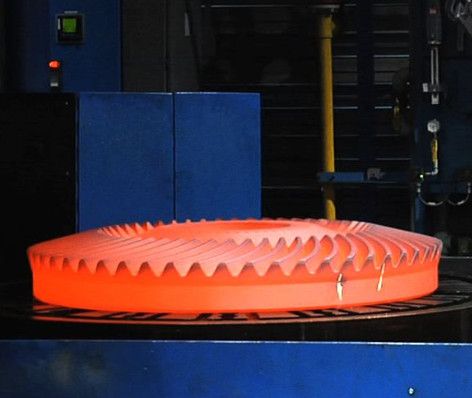

Forging

Lathe turning

Milling

Heat treatment

OD/ID grinding

Lapping

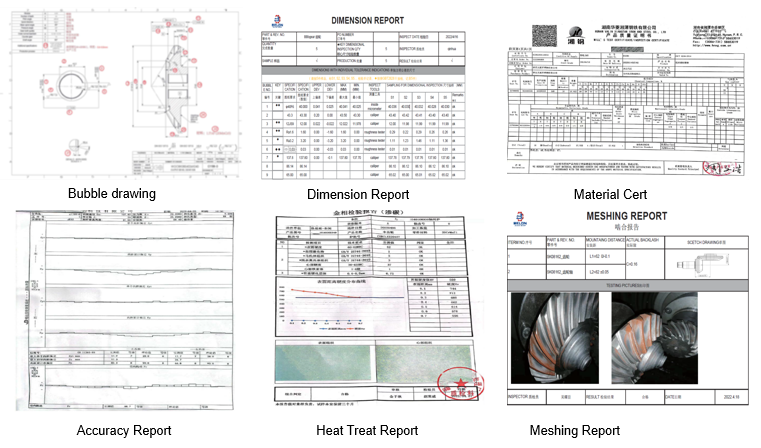

Inspection

Reports

Packages

Our video show

Write your message here and send it to us