Powder metallurgy gears

Powder metallurgy is a manufacturing prat involves compacting metal powders under high pressure and then sintering them at high temperatures to form solid parts.

Powder metal gears are widely used in various industries such as automotive, industrial equipment and power transmission applications.

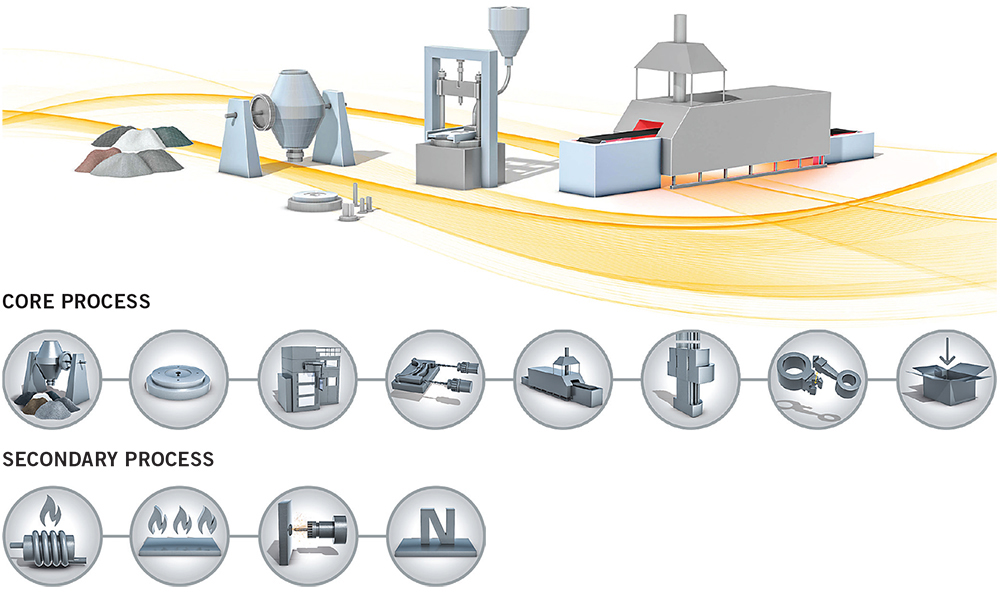

The core process of powder metallurgy includes powder mixing, tooling, powder pressing, green machining, sintering, sizing, packaging and final inspection. Secondary operations include induction hardening, heat treatment machining and nitriding.

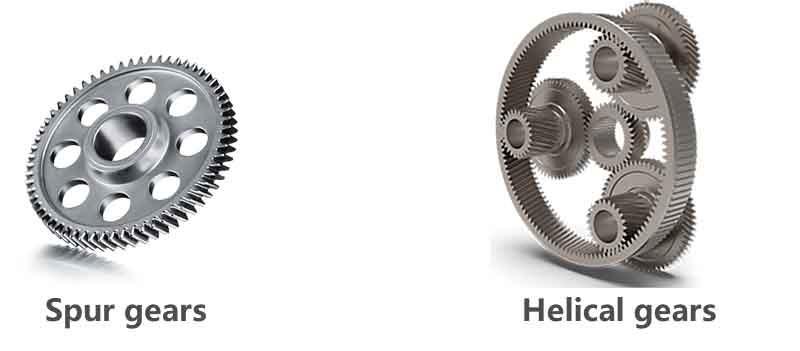

Powder metal gears, like gears produced by other manufacturing techniques, can be processed into various tooth shapes according to requirements. Some common tooth shapes for powder metal gears include: spur gears, helical gears.

Powder metal material:

When selecting materials for powder metallurgy gears, several factors need to be considered: mechanical properties, density, lubrication and wear, cost

Application fields:

Powder metal gears are used in a wide variety of automotive systems, including:

1. Gearbox: Powder metal gears are widely used in automatic and manual gearboxes to provide reliable and efficient power transmission between the engine and the wheels. Their high strength and wear resistance ensure smooth shifting, improved gear mesh and extended transmission life.

2. Electric Powertrains: As the automotive industry shifts to electric vehicles (EVs), powder metal gears play a vital role in electric powertrains. These gears are used in electric motor drives, gearboxes and differentials to provide the necessary torque and speed required for optimal EV performance.

3. Steering system: The steering system uses powder metal gears to transmit power from the steering wheel to the wheels. Their durability, precision and quiet operation contribute to responsive and accurate steering control.

Post time: Aug-28-2023