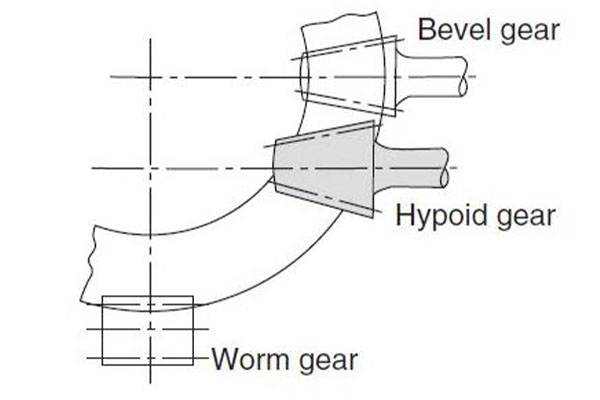

Spiral bevel gears and hypoid bevel gears are the main transmission methods used in automobile final reducers. What is the difference between them?

Difference Between Hypoid Bevel Gear And Spiral Bevel Gear

Spiral bevel gear, the axes of the driving and driven gears intersect at one point, and the angle of intersection can be arbitrary, but in most automobile drive axles, the main reducer gear pair is arranged vertically at a 90° angle the way. Due to the overlap of the end faces of the gear teeth, at least two or more pairs of gear teeth mesh at the same time. Therefore, the spiral bevel gear can withstand a larger load. In addition, the gear teeth are not meshed at the same time over the full tooth length, but are gradually meshed by the teeth. One end is continuously turned to the other end, so that it works smoothly, and even at high speed, the noise and vibration are very small.

Hypoid gears, the axes of the driving and driven gears do not intersect but intersect in space. The intersecting angles of the hypoid gears are mostly perpendicular to different planes at a 90° angle. The driving gear shaft has an upward or downward offset relative to the driven gear shaft (referred to as upper or lower offset accordingly). When the offset is large to a certain extent, one gear shaft can pass by the other gear shaft. In this way, compact bearings can be arranged on both sides of each gear, which is beneficial for enhancing the support rigidity and ensuring the correct meshing of the gear teeth, thereby increasing the life of the gears. It is suitable for through-type drive axles.

Unlike spiral bevel gears where the helix angles of the driving and driven gears are equal because the axes of the gear pairs intersect, the axis offset of the hypoid gear pair makes the driving gear helix angle greater than the driven gear helix angle. Therefore, although the normal modulus of the hypoid bevel gear pair is equal, the end face modulus is not equal (the end face modulus of the driving gear is greater than the end face modulus of the driven gear). This makes the driving gear of the quasi double sided bevel gear transmission have a larger diameter and better strength and rigidity than the driving gear of the corresponding spiral bevel gear transmission. In addition, due to the large diameter and helix angle of the driving gear of the hypoid bevel gear transmission, the contact stress on the tooth surface is reduced and the service life is increased.

Custom Gear Belon Gear Manufacturer

However, when the transmission is relatively small, the driving gear of the quasi double sided bevel gear transmission is too large compared to the driving gear of the spiral bevel gear. At this time, it is more reasonable to choose the spiral bevel gear.

Post time: Mar-11-2022