Due to the nature of their applications, miter gears are often precision machined to ensure smooth operation and minimize friction. This is particularly important for maintaining efficiency and reducing wear in mechanical systems. Miter gears are widely used in a range of industries, including automotive, robotics, woodworking machinery, and various mechanical systems where changes in direction or transmission of power at right angles are essential.

We covers an area of 25 acres and a building area of 26,000 square meters ,also equipped with advance production and inspection equipment to meet customer’s different requirements .

Forging

Lathe turning

Milling

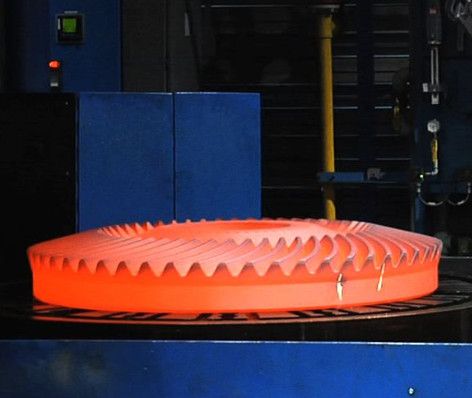

Heat treatment

OD/ID grinding

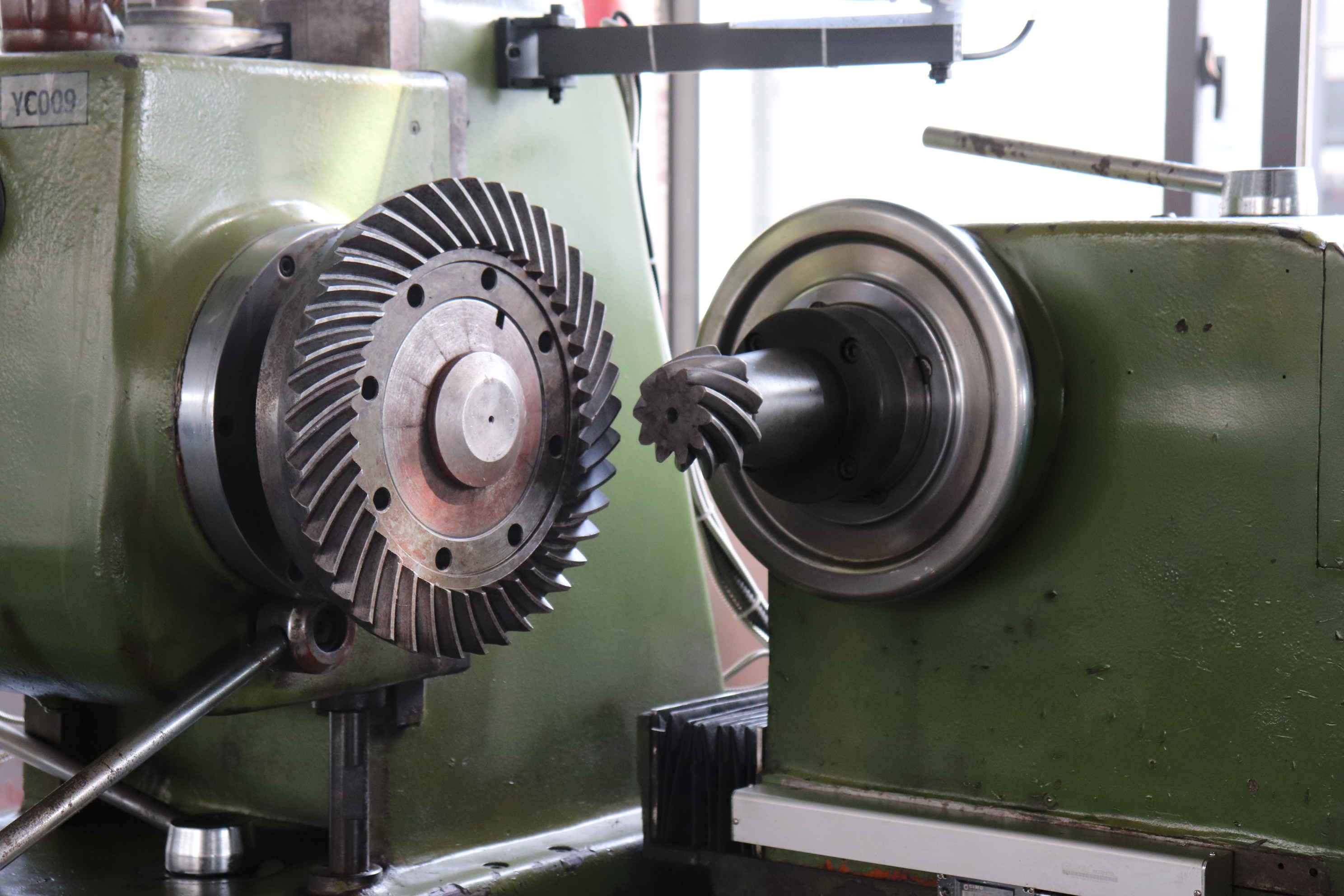

Lapping

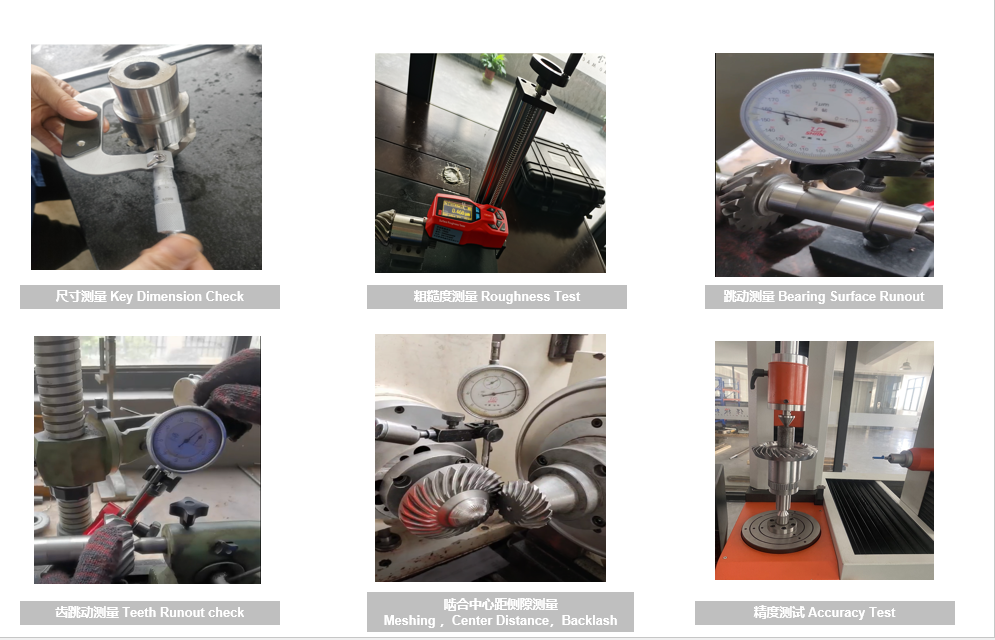

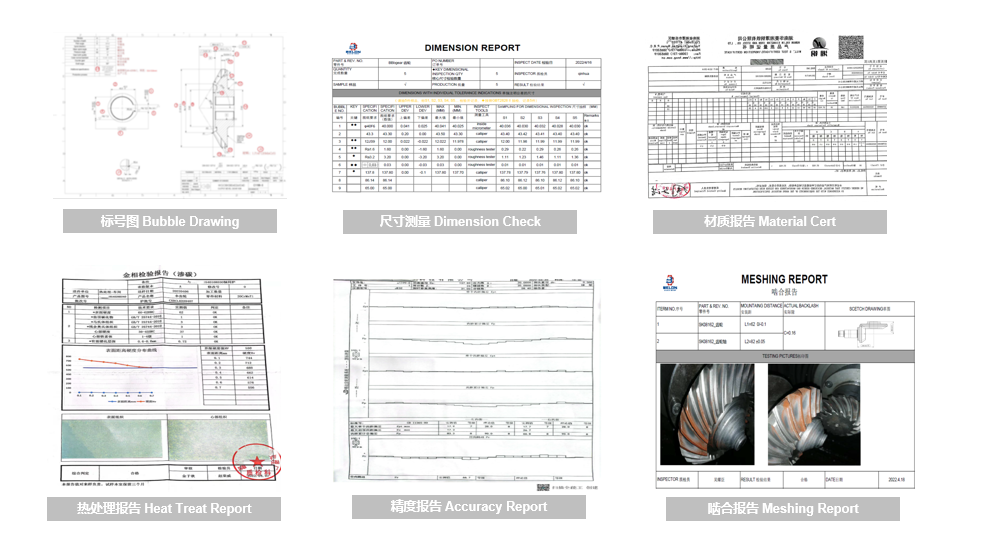

Reports : we will provide below reports along with pictures and videos to customers before every shipping for approval for lapping bevel gears .

1) Bubble drawing

2) Dimension report

3) Material cert

4) Accuracy report

5) Heat Treat report

6) Meshing report

Inner package

Inner package

Carton

wooden package