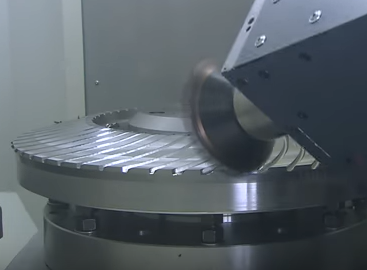

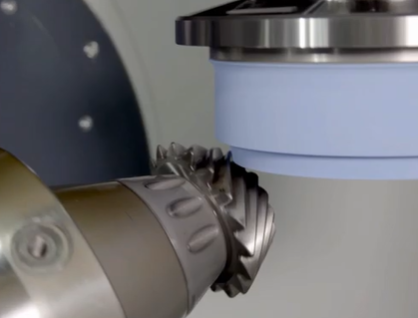

Each gear undergoes a meticulous grinding process to achieve unparalleled precision. Our state-of-the-art grinding facilities enable us to maintain tight tolerances, ensuring a perfect fit and optimal meshing between gears. This results in reduced friction, increased efficiency, and extended product life.

The combination of Gleason precision and 20CrMnTi alloy resilience ensures long-term reliability, minimizing downtime and maintenance costs.

At our company, we understand the importance of quality and performance in gear transmission. That's why our Precision Spiral Bevel Gears are manufactured to the highest standards, using the latest manufacturing techniques and quality control processes. Each gear is rigorously tested to ensure it meets our stringent performance criteria, so you can have complete confidence in its performance.

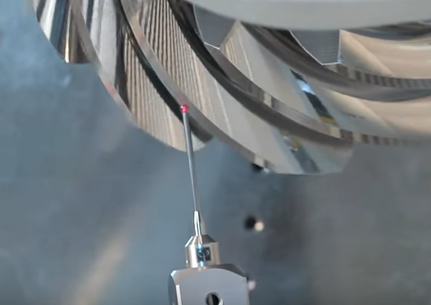

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

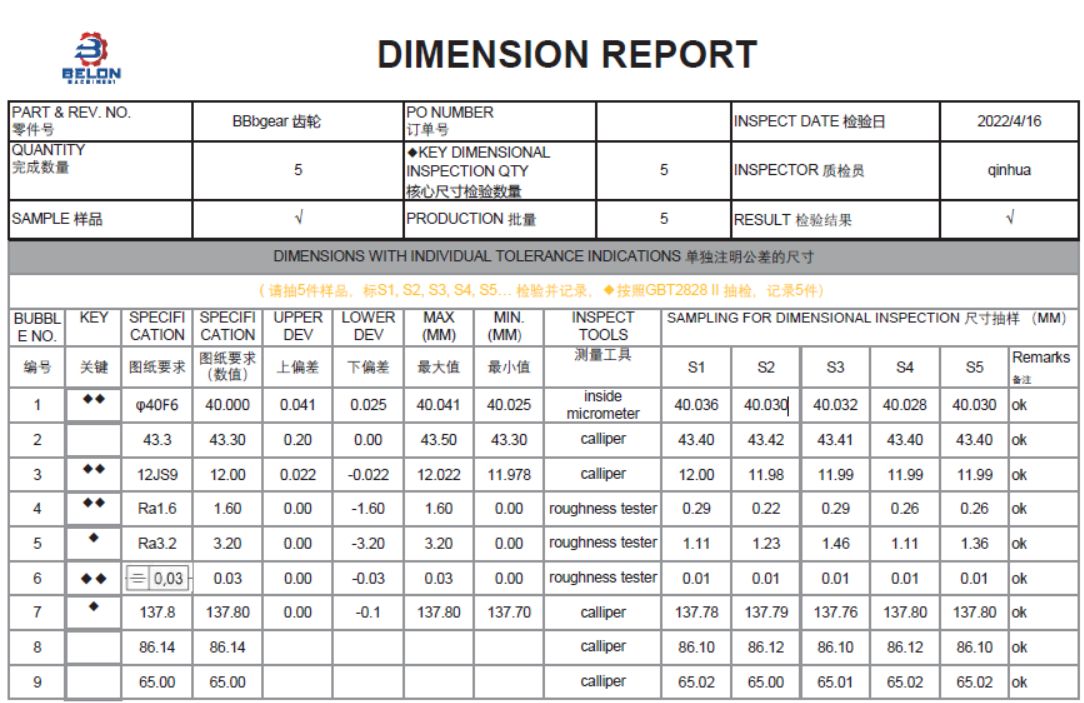

1) Bubble drawing

2) Dimension report

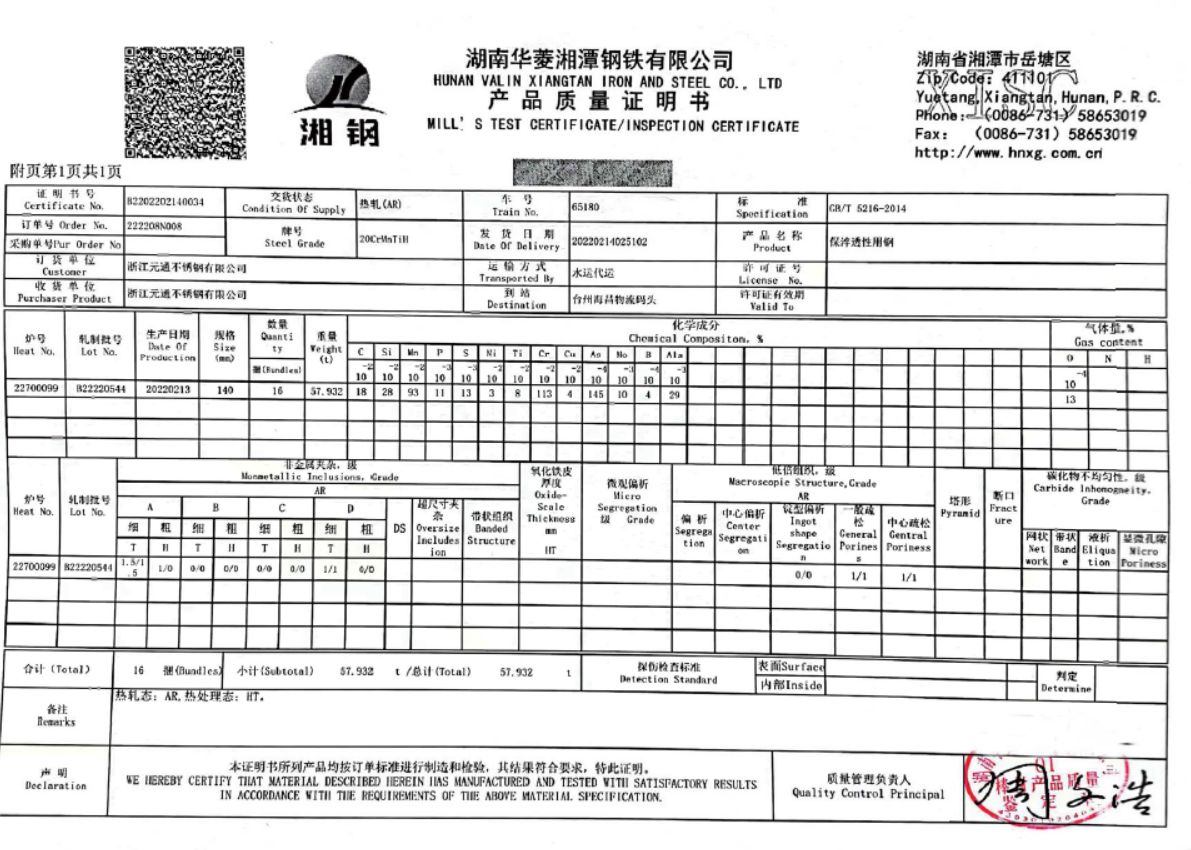

3) Material cert

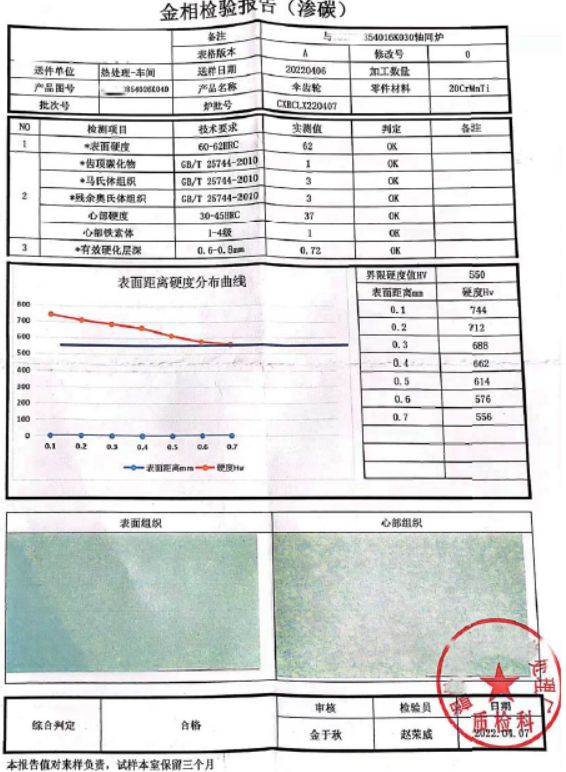

4) Heat treat report

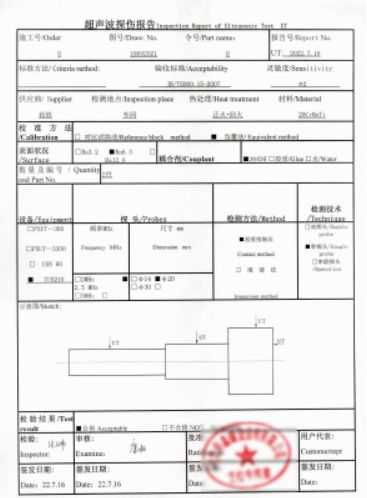

5) Ultrasonic Test report (UT)

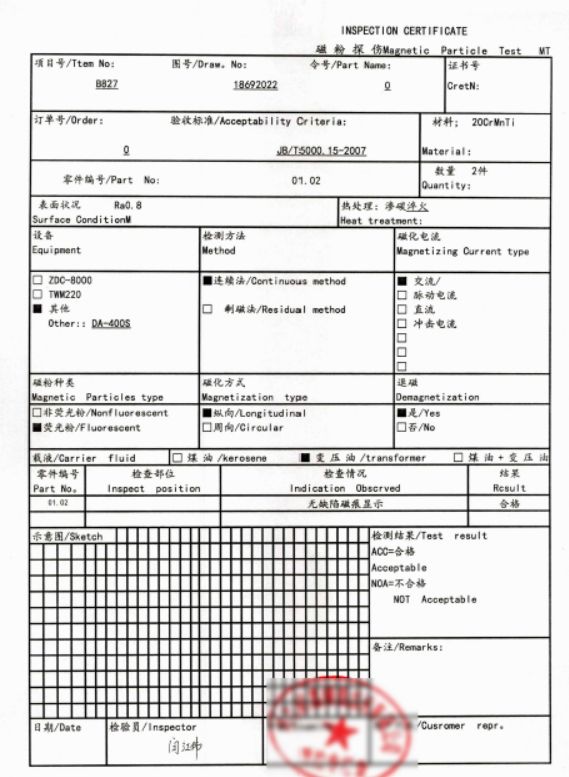

6) Magnetic Particle Test report (MT)

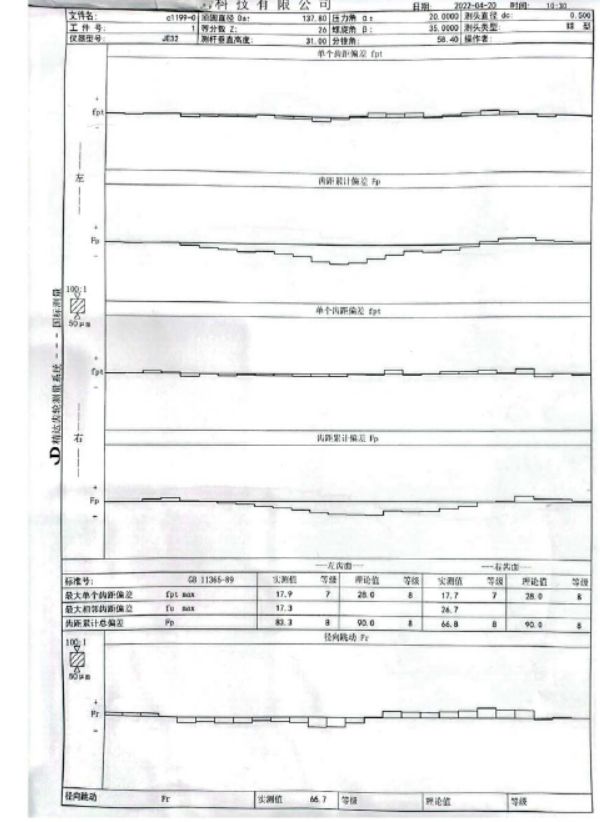

Meshing test report

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

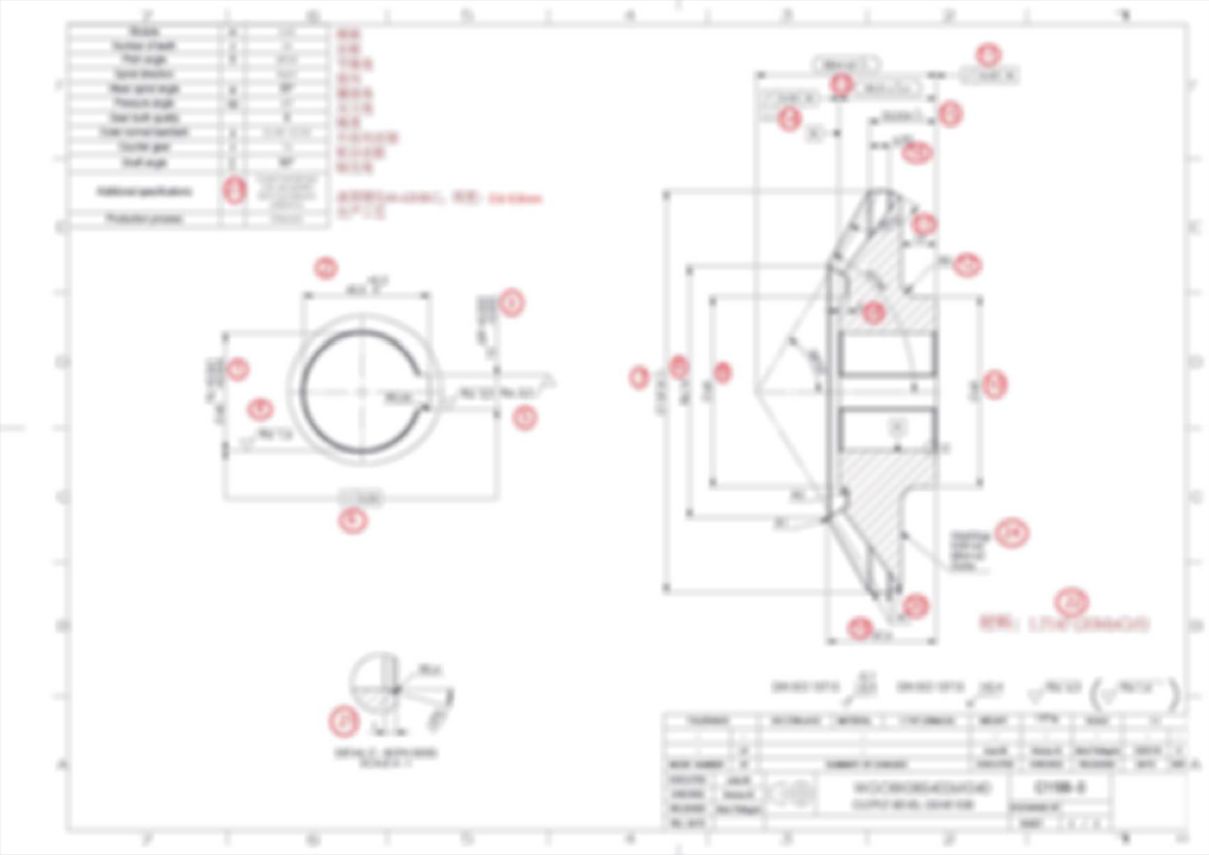

→ Any Modules

→ Any Numbers of Teeth

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

raw material

rough cutting

turning

quenching and tempering

gear milling

Heat treat

gear milling

testing