gearbox worm wheel - China Manufacturers, Suppliers, Factory

To meet the customers' over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for gearbox worm wheel, Pinion Gears, Worm Gear Set, Helical Gear Transmission,Custom Spur Gears. We feel that a passionate, ground breaking and well-trained workforce can create fantastic and mutually useful business associations with you quickly. Be sure to really feel totally free to contact us for more particulars. The product will supply to all over the world, such as Europe, America, Australia,Czech, Sydney,Spain, Guinea.With a fully integrated operation system, our company has won a good fame for our high quality products, reasonable prices and good services. Meanwhile, we have established a strict quality management system conducted in material incoming, processing and delivery. Abiding by the principle of "Credit first and customer supremacy", we sincerely welcome clients from home and abroad to cooperate with us and advance together to create a brilliant future.

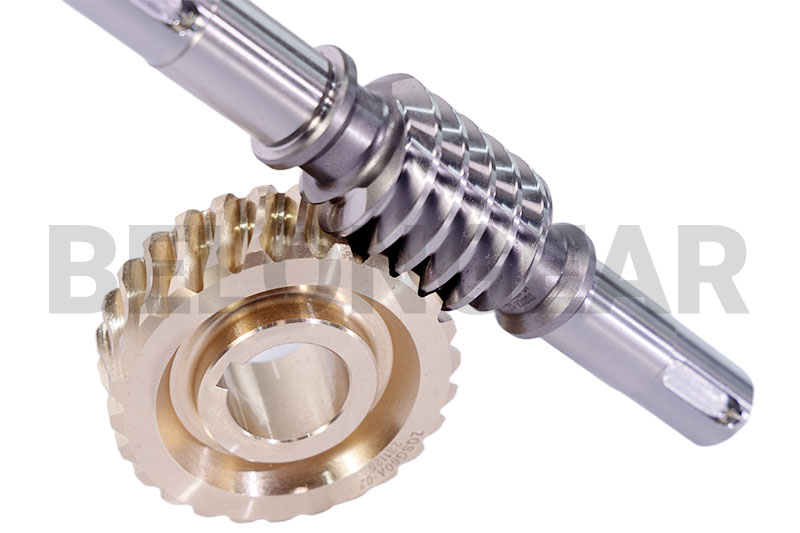

Related Products