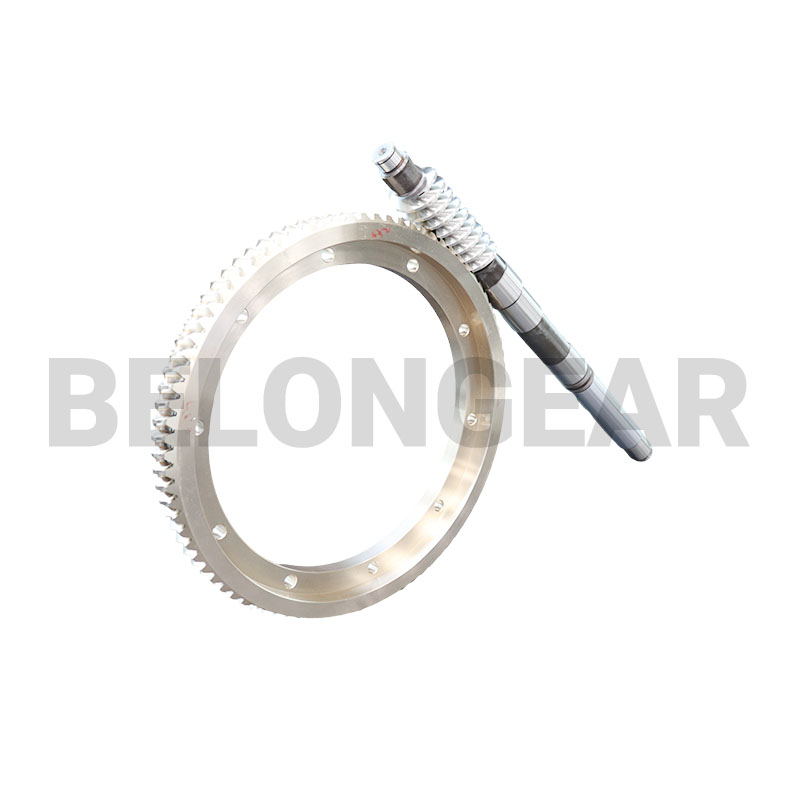

gear pinion - Factory, Suppliers, Manufacturers from China

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of gear pinion, Straight Spur Gear, Hypoid Definition, Helical Gear Drive,Double Spur Gear. We are sincerely looking forward to establishing good cooperative relationships with customers from at home and abroad for creating a bright future together. The product will supply to all over the world, such as Europe, America, Australia,Uruguay, Las Vegas,Curacao, Slovenia.We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, thorough meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

Related Products