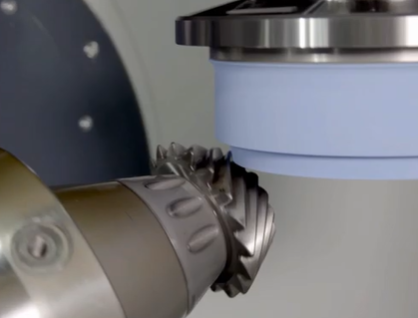

The bevel gear spiral drive system finds applications in different industries and machines, including automotive rear axle differentials, marine propulsion systems, power tools, agricultural machinery, and other mechanical systems where torque needs to be transferred between intersecting shafts. The design of the system allows for efficient power transmission while accommodating changes in direction and orientation of the shafts.

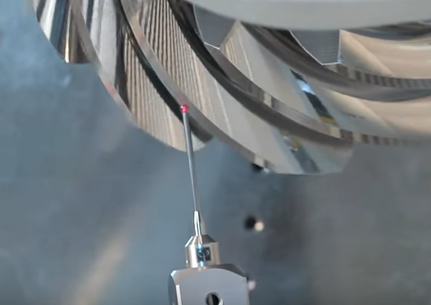

What kind of reports will be provided to customers before shipping for grinding large spiral bevel gears ?

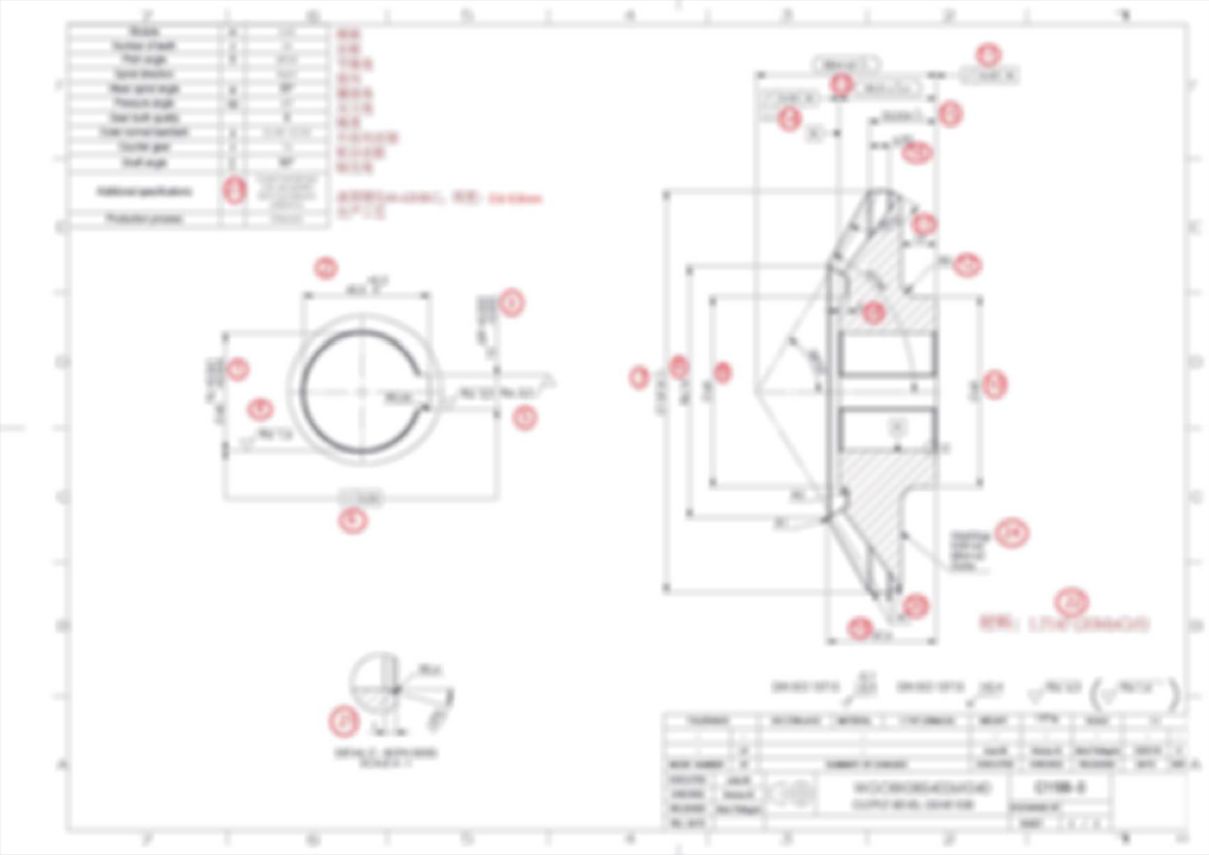

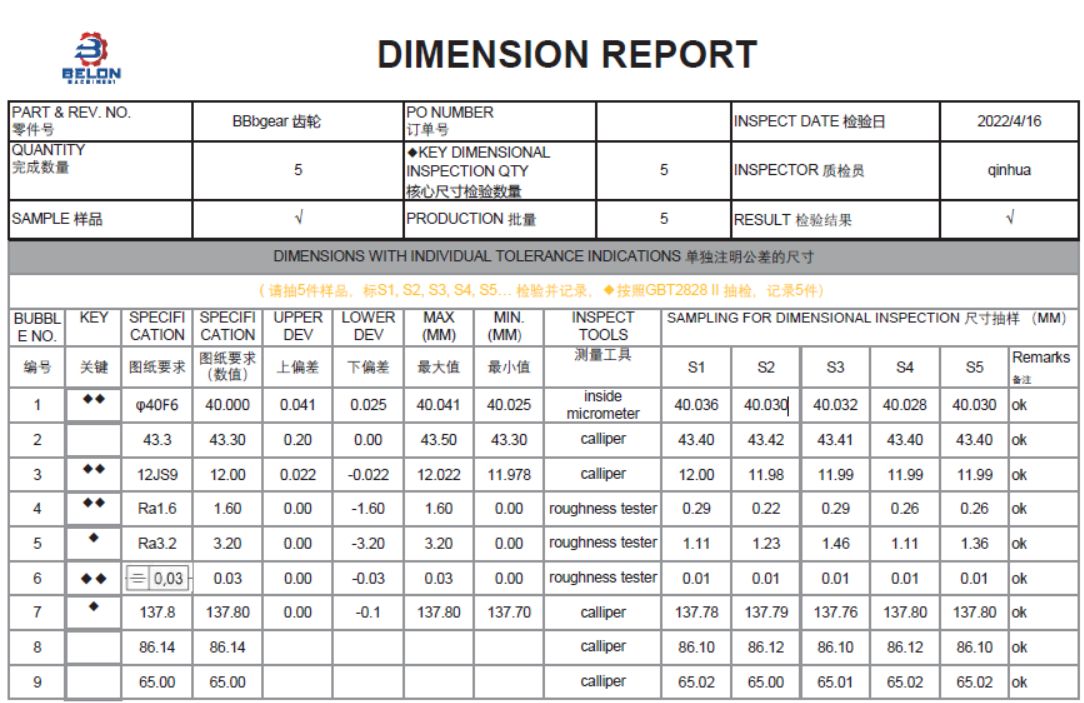

1) Bubble drawing

2) Dimension report

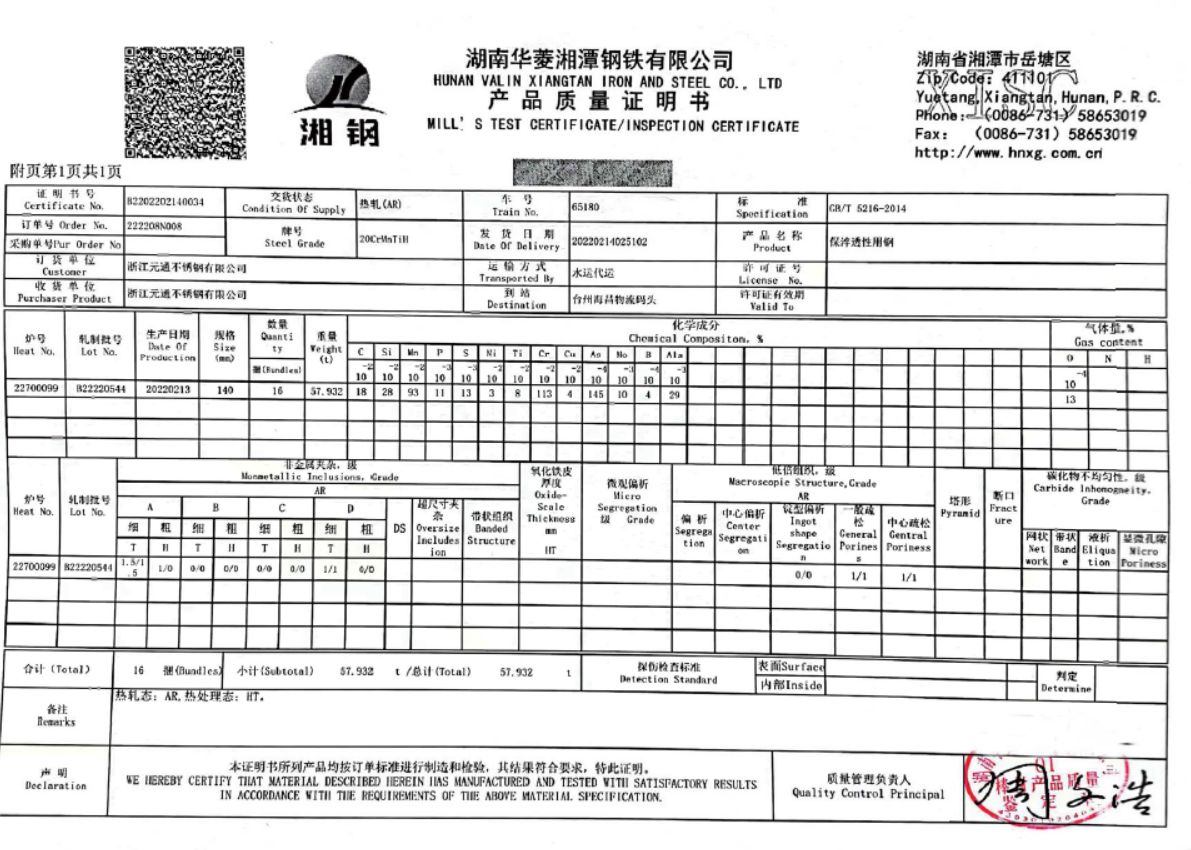

3) Material cert

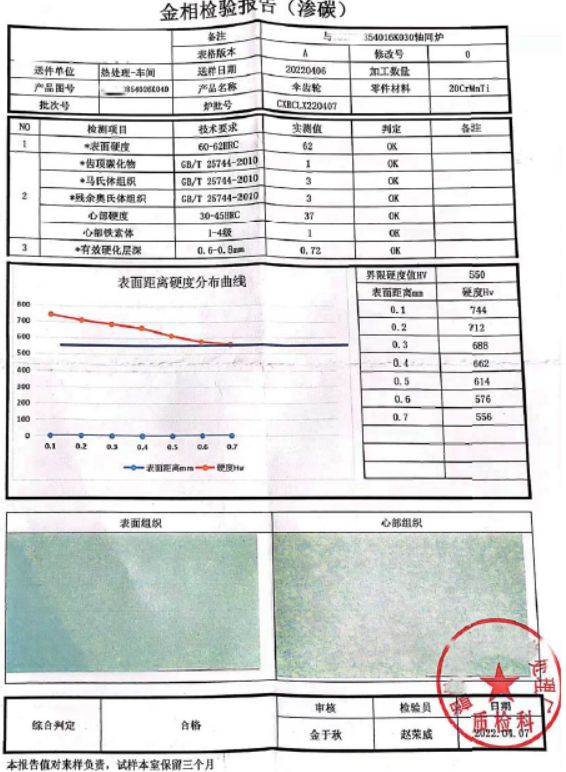

4) Heat treat report

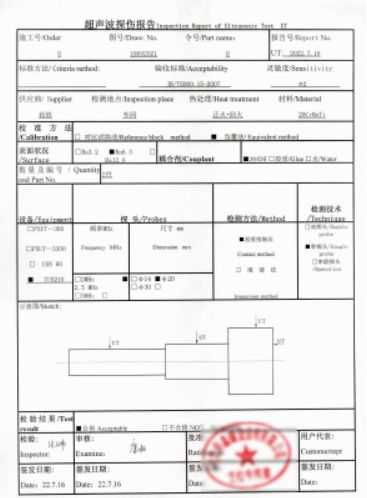

5) Ultrasonic Test report (UT)

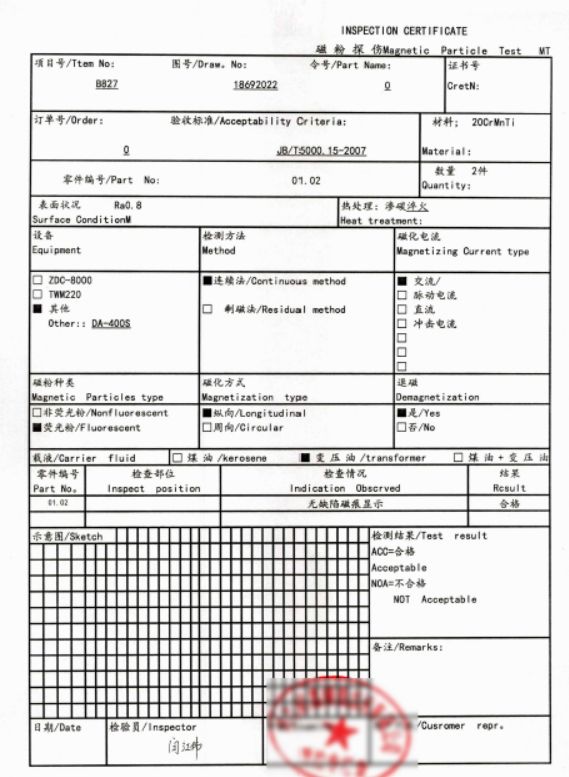

6) Magnetic Particle Test report (MT)

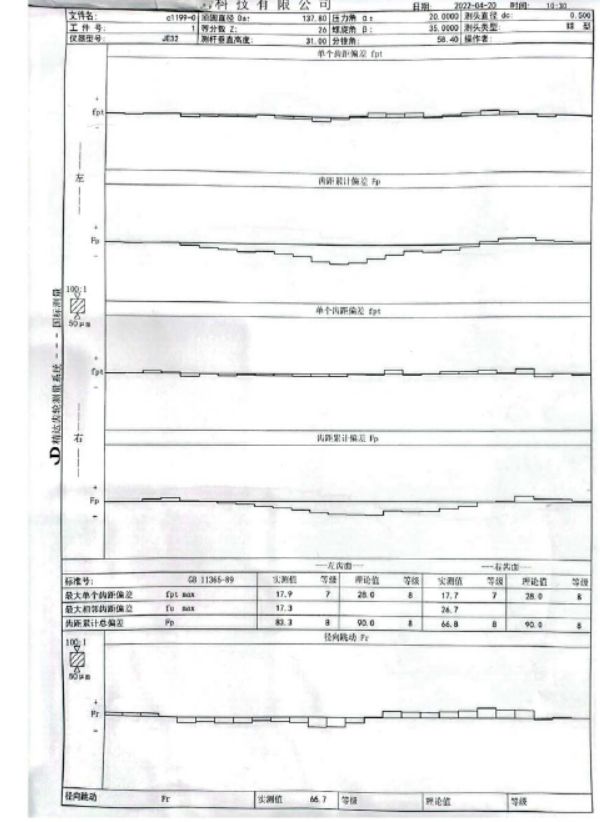

Meshing test report

We convers an area of 200000 square meters ,also equipped with advance production and inspection equipment to meet customer’s demand . We has introduced the largest size, the China first gear-specific Gleason FT16000 five-axis machining center since the cooperation between Gleason and Holler .

→ Any Modules

→ Any Numbers of Teeth

→ Highest accuracy DIN5

→ High efficiency ,high precision

Bringing the dream productivity, flexibility and economy for small batch.

raw material

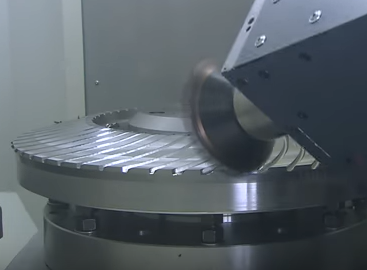

rough cutting

turning

quenching and tempering

gear milling

Heat treat

gear milling

testing