These kinds of bevel gear set are used at types of gearmotors and some of them are common types .,with low noise and high wear-resistant .

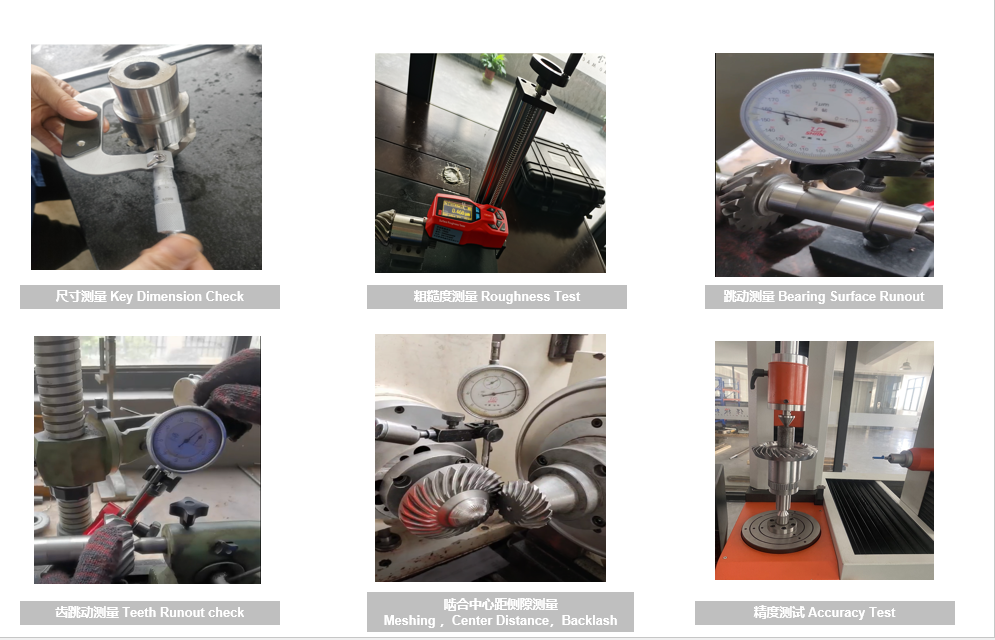

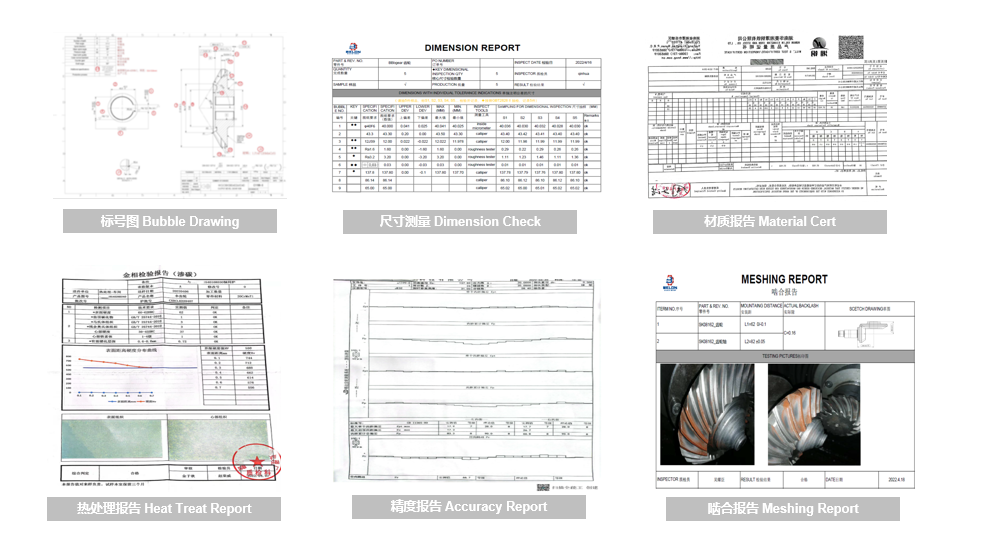

The important reports for such kinds of bevel gears are :

1) Dimension report (plus bearing surface runout testing video)

2) Material report before heat treat

3) Heat Treat report plus hardness and Metallographic

4) Accuracy test report

5) Meshing Test report (plus center distance ,backlash testing videos)

The production process for such kinds of bevel gears set is as following :

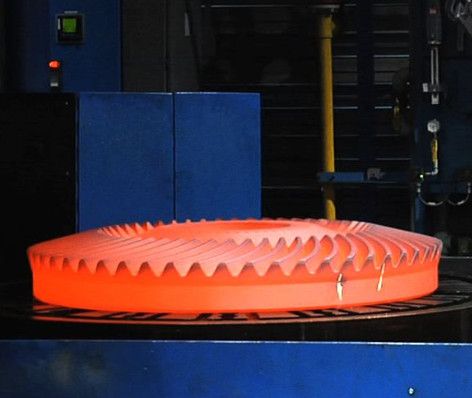

1) Forging

2) Rough cutting

3) Gear turning

4) Quenching and tempering heat treat

5) Gear milling for teeh

6) Heat Treat like carburizing

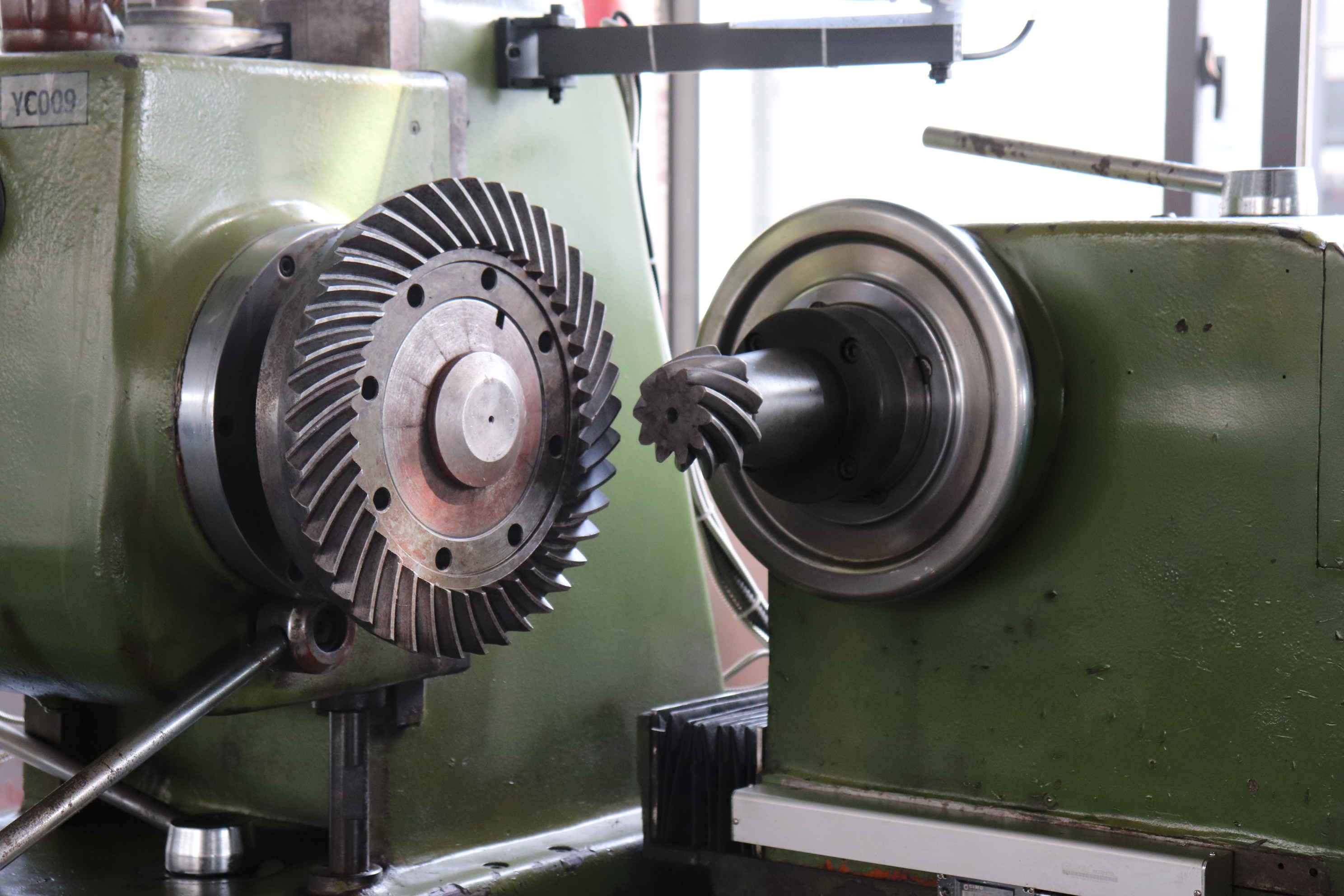

7) Gear Lapping in order to improve the gear surface quality

8) Complete inspection

We covers an area of 25 acres and a building area of 26,000 square meters ,also equipped with advance production and inspection equipment to meet customer’s different requirements .

Forging

Lathe turning

Milling

Heat treatment

OD/ID grinding

Lapping

Reports :,we will provide below reports along with pictures and videos to customers before every shipping for approval for lapping bevel gears .

1) Bubble drawing

2) Dimension report

3) Material cert

4) Accuracy report

5) Heat Treat report

6) Meshing report

Inner package

Inner package

Carton

wooden package