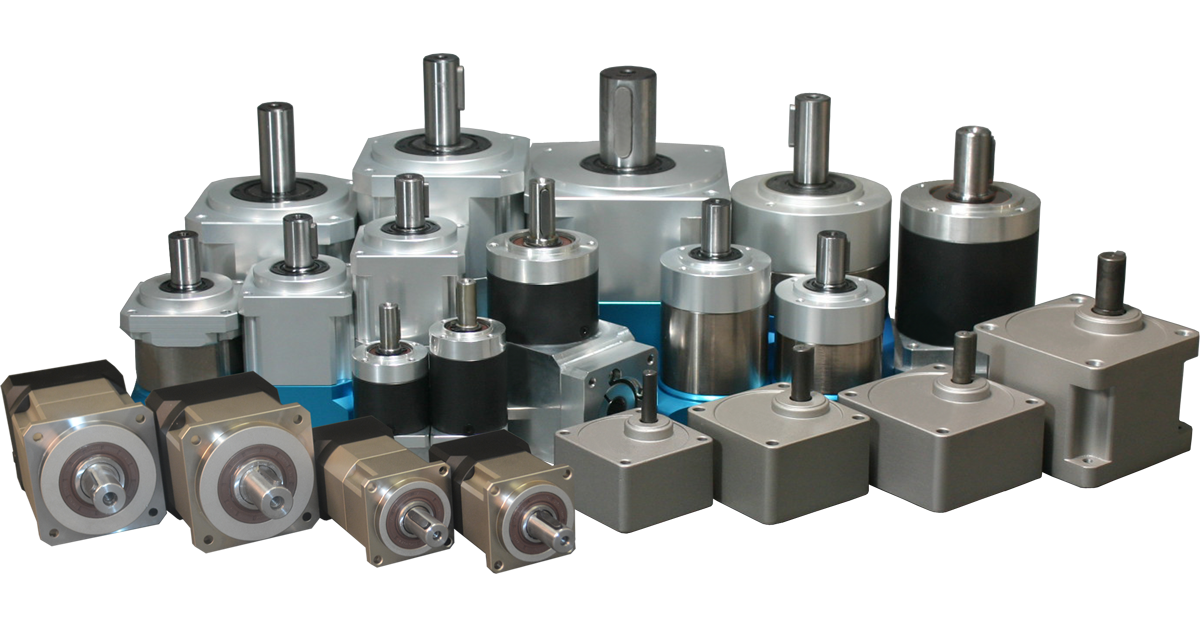

Gearboxes Gears

Robotic gearboxes may utilize various types of gear depending on the specific requirements of the robot's design and functionality. Some of the common types of gears used in robotic gearboxes include:

- Spur Gears: Spur gears are the simplest and most commonly used type of gear. They have straight teeth that are parallel to the axis of rotation. Spur gears are efficient for transferring power between parallel shafts and are often used in robotic gearboxes for moderate-speed applications.

- Helical Gears: Helical gears have angled teeth that are cut at an angle to the gear axis. These gears offer smoother operation and higher load-bearing capacity compared to spur gears. They are suitable for applications where low noise and high torque transmission are required, such as robotic joints and high-speed robotic arms.

- Bevel Gears: Bevel gears have conical-shaped teeth and are used to transmit motion between intersecting shafts. They are commonly used in robotic gearboxes for changing the direction of power transmission, such as in differential mechanisms for robotic drive trains.

- Planetary Gears: Planetary gears consist of a central gear (sun gear) surrounded by one or more outer gears (planet gears) that rotate around it. They offer compactness, high torque transmission, and versatility in speed reduction or amplification. Planetary gearsets are often employed in robotic gearboxes for high-torque applications, such as robotic arms and lifting mechanisms.

- Worm Gears: Worm gears consist of a worm (a screw-like gear) and a mating gear called a worm wheel. They provide high gear reduction ratios and are suitable for applications where large torque multiplication is required, such as in robotic actuators and lifting mechanisms.

- Cycloidal Gears: Cycloidal gears use cycloidal-shaped teeth to achieve smooth and quiet operation. They offer high precision and are often used in robotic gearboxes for applications where precise positioning and motion control are essential, such as in industrial robots and CNC machines.

- Rack and Pinion: Rack and pinion gears consist of a linear gear (rack) and a circular gear (pinion) meshed together. They are commonly used in robotic gearboxes for linear motion applications, such as in Cartesian robots and robotic gantries.

The selection of gears for a robotic gearbox depends on factors such as the desired speed, torque, efficiency, noise level, space constraints, and cost considerations. Engineers choose the most suitable gear types and configurations to optimize the performance and reliability of the robotic system.

Robotic Arms Gears

Robotic arms are essential components of many robotic systems, used in various applications ranging from manufacturing and assembly to healthcare and research. The types of gears used in robotic arms depend on factors such as the arm's design, intended tasks, payload capacity, and required precision. Here are some common types of gears used in robotic arms:

- Harmonic Drives: Harmonic drives, also known as strain wave gears, are widely used in robotic arms due to their compact design, high torque density, and precise motion control. They consist of three main components: a wave generator, a flex spline (thin-walled flexible gear), and a circular spline. Harmonic drives offer zero backlash and high reduction ratios, making them suitable for applications requiring precise positioning and smooth motion, such as robotic surgery and industrial automation.

- Cycloidal Gears: Cycloidal gears, also known as cycloidal drives or cyclo drives, utilize cycloidal-shaped teeth to achieve smooth and quiet operation. They offer high torque transmission, minimal backlash, and excellent shock absorption, making them suitable for robotic arms in harsh environments or applications requiring high load capacity and precision.

- Harmonic Planetary Gears: Harmonic planetary gears combine the principles of harmonic drives and planetary gears. They feature a flexible ring gear (similar to a flexspline in harmonic drives) and multiple planet gears rotating around a central sun gear. Harmonic planetary gears offer high torque transmission, compactness, and precision motion control, making them suitable for robotic arms in applications such as pick-and-place operations and material handling.

- Planetary Gears: Planetary gears are commonly used in robotic arms for their compact design, high torque transmission, and versatility in speed reduction or amplification. They consist of a central sun gear, multiple planet gears, and an outer ring gear. Planetary gears offer high efficiency, minimal backlash, and excellent load-bearing capacity, making them suitable for various robotic arm applications, including industrial robots and collaborative robots (cobots).

- Spur Gears: Spur gears are simple and widely used in robotic arms for their ease of manufacturing, cost-effectiveness, and suitability for moderate-load applications. They consist of straight teeth parallel to the gear axis and are commonly used in robotic arm joints or transmission systems where high precision is not critical.

- Bevel Gears: Bevel gears are used in robotic arms to transmit motion between intersecting shafts at different angles. They offer high efficiency, smooth operation, and compact design, making them suitable for robotic arm applications requiring changes in direction, such as joint mechanisms or end effectors.

The selection of gears for robotic arms depends on the specific requirements of the application, including payload capacity, precision, speed, size constraints, and environmental factors. Engineers choose the most suitable gear types and configurations to optimize the performance, reliability, and efficiency of the robotic arm.

Wheel Drives Gears

In-wheel drives for robotics, various types of gears are used to transmit power from the motor to the wheels, allowing the robot to move and navigate its environment. The choice of gears depends on factors such as the desired speed, torque, efficiency, and size constraints. Here are some common types of gears used in wheel drives for robotics:

- Spur Gears: Spur gears are one of the most common types of gears used in wheel drives. They have straight teeth that are parallel to the axis of rotation and are efficient for transferring power between parallel shafts. Spur gears are suitable for applications where simplicity, cost-effectiveness, and moderate loads are required.

- Bevel Gears: Bevel gears are used in wheel drives to transmit motion between shafts that intersect at an angle. They have conical-shaped teeth and are commonly used in robotic wheel drives to change the direction of power transmission, such as in differential mechanisms for differential-steering robots.

- Planetary Gears: Planetary gears are compact and offer high torque transmission, making them suitable for robotic wheel drives. They consist of a central sun gear, multiple planet gears, and an outer ring gear. Planetary gears are often used in robotic wheel drives to achieve high reduction ratios and torque multiplication in a small package.

- Worm Gears: Worm gears consist of a worm (a screw-like gear) and a mating gear called a worm wheel. They provide high gear reduction ratios and are suitable for applications where large torque multiplication is required, such as in robotic wheel drives for heavy-duty vehicles or industrial robots.

- Helical Gears: Helical gears have angled teeth that are cut at an angle to the gear axis. They offer smoother operation and higher load-bearing capacity compared to spur gears. Helical gears are suitable for robotic wheel drives where low noise and high torque transmission are required, such as in mobile robots navigating indoor environments.

- Rack and Pinion: Rack and pinion gears are used in robotic wheel drives to convert rotational motion into linear motion. They consist of a circular gear (pinion) meshed with a linear gear (rack). Rack and pinion gears are commonly used in linear motion systems for robotic wheel drives, such as in Cartesian robots and CNC machines.

The selection of gears for robotic wheel drives depends on factors such as the robot's size, weight, terrain, speed requirements, and power source. Engineers choose the most suitable gear types and configurations to optimize the performance, efficiency, and reliability of the robot's locomotion system.

Grippers and End Effectors Gears

Grippers and end effectors are components attached to the end of robotic arms for grasping and manipulating objects. While gears may not always be the primary component in grippers and end effectors, they can be incorporated into their mechanisms for specific functionalities. Here's how gears might be used in the equipment associated with grippers and end effectors:

- Actuators: Grippers and end effectors often require actuators to open and close the gripping mechanism. Depending on the design, these actuators may incorporate gears to translate the rotational motion of a motor into the linear motion needed to open and close the gripper fingers. Gears can be used to amplify torque or adjust the speed of movement in these actuators.

- Transmission Systems: In some cases, grippers and end effectors may require transmission systems to transfer power from the actuator to the gripping mechanism. Gears can be used within these transmission systems to adjust the direction, speed, or torque of the transmitted power, allowing for precise control over the gripping action.

- Adjustment Mechanisms: Grippers and end effectors often need to accommodate objects of different sizes and shapes. Gears can be used in adjustment mechanisms to control the position or spacing of the gripper fingers, allowing them to adapt to various objects without the need for manual adjustment.

- Safety Mechanisms: Some grippers and end effectors incorporate safety features to prevent damage to the gripper or the objects being handled. Gears can be used in these safety mechanisms to provide overload protection or to disengage the gripper in case of excessive force or jamming.

- Positioning Systems: Grippers and end effectors may require precise positioning to grasp objects accurately. Gears can be used in positioning systems to control the movement of the gripper fingers with high accuracy, allowing for reliable and repeatable gripping operations.

- End Effector Attachments: In addition to gripper fingers, end effectors may include other attachments such as suction cups, magnets, or cutting tools. Gears can be used to control the movement or operation of these attachments, allowing for versatile functionality in handling different types of objects.

While gears may not be the primary component in grippers and end effectors, they can play a crucial role in enhancing the functionality, precision, and versatility of these robotic components. The specific design and use of gears in grippers and end effectors will depend on the requirements of the application and the desired performance characteristics.