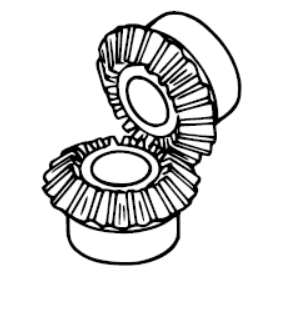

Online Exporter Gear Spiral Bevel - Miter Gear Set With Ratio 1:1 – Belon Detail:

Miter gear working method

Advantages of zero bevel gears are:

1)The force acting on the gear is the same as that of a straight bevel gear.

2) Higher strength and lower noise than straight bevel gears (in general).

3) Gear grinding can be done to obtain high-precision gears .

Manufacturing Plant

Production Process

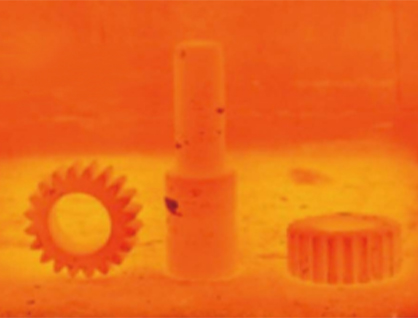

Raw Material

Rough Cutting

Turning

Quenching And Tempering

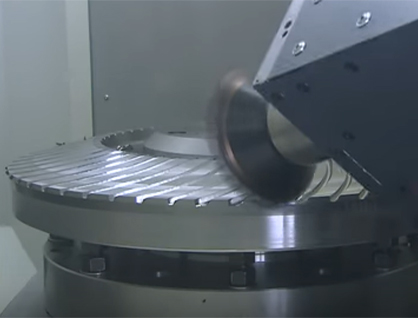

Gear Milling

Heat Treat

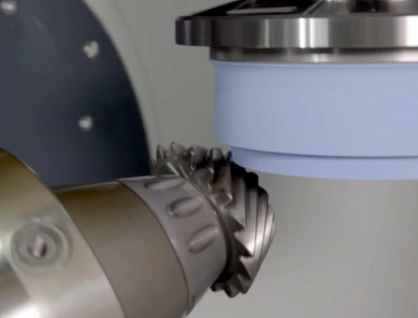

Gear Grinding

Testing

Inspection

Reports

We will provide compete quality reports to customers before every shipping like dimension report ,material cert ,heat treat report ,accuracy report and other customer’s required quality files .

Heat Treat report

Flaw Detection report

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

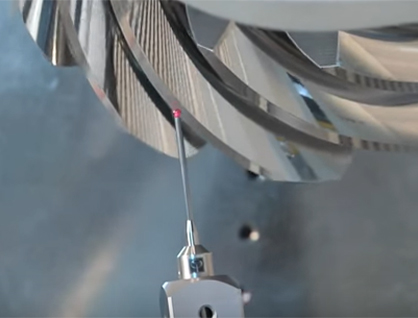

Zero Bevel Gear Milling At Gleason Machine

Product detail pictures:

Related Product Guide:

Our mission is to become an innovative supplier of high-tech digital and communication devices by providing value added design, world-class manufacturing, and service capabilities for Online Exporter Gear Spiral Bevel - Miter Gear Set With Ratio 1:1 – Belon , The product will supply to all over the world, such as: Liberia, London, Russia, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to provide customers with high quality products, provide high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!

Write your message here and send it to us