Low MOQ for Bevel Gear Pair - Alloy steel Lapped bevel gear sets in gearmotor – Belon Detail:

Product details

These kinds of bevel gear set are used at types of gearmotors and some of them are common types .,with low noise and high wear-resistant .

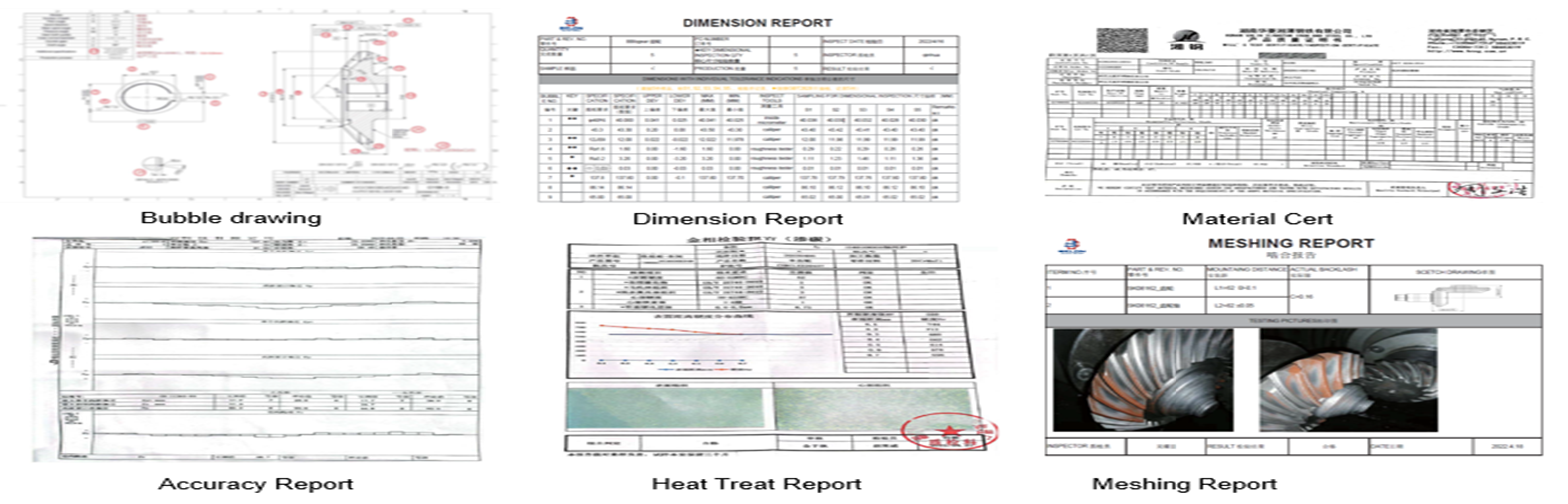

The important reports for such kinds of bevel gears are :

1) Dimension report (plus bearing surface runout testing video)

2) Material report before heat treat

3) Heat Treat report plus hardness and Metallographic

4) Accuracy test report

5) Meshing Test report (plus center distance ,backlash testing videos)

The production process for such kinds of bevel gears set is as following :

1) Forging

2) Rough cutting

3) Gear turning

4) Quenching and tempering heat treat

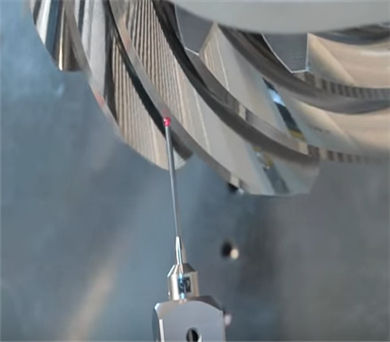

5) Gear milling for teeh

6) Heat Treat like carburizing

7) Gear Lapping in order to improve the gear surface quality

8) Complete inspection

Manufacturing Plant :

We covers an area of 25 acres and a building area of 26,000 square meters ,also equipped with advance production and inspection equipment to meet customer’s different requirements .

Production Process:

Raw Material

Rough Cutting

Gear Turning

Quenching & Tempering

Gear Milling

Heat Treat

Gear Lapping

Testing

Inspection :

Reports :,we will provide below reports along with pictures and videos to customers before every shipping for approval for lapping bevel gears .

1) Bubble drawing

2) Dimension report

3) Material cert

4) Accuracy report

5) Heat Treat report

6) Meshing report

Packages :

Inner package

Inner package

Carton

wooden package

Our video show

Industrial gearbox spiral bevel gear milling

Meshing test for lapping bevel gear

Surface runout testing for bevel gears

Lapping bevel gear or grinding bevel gears

Spiral bevel gears

Bevel gear broaching

Bevel gear lapping VS bevel gear grinding

Spiral bevel gear milling

Industrial robot spiral bevel gear milling method

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" plus the theory of "quality the basic, have faith in the main and management the advanced" for Low MOQ for Bevel Gear Pair - Alloy steel Lapped bevel gear sets in gearmotor – Belon , The product will supply to all over the world, such as: Luxembourg, Bhutan, Korea, Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!