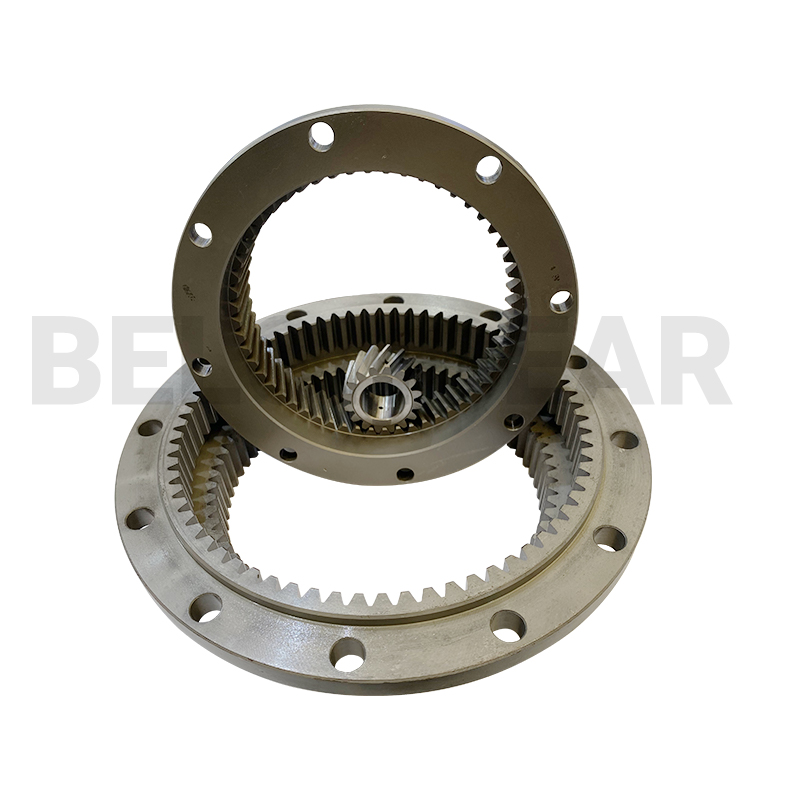

Internal spur gears for sale Detail:

Production Process

Inspection

Reports

Packages

Our video show

Product detail pictures:

Related Product Guide:

Our intention should be to fulfill our consumers by offering golden provider, superior price and superior quality for Internal spur gears for sale , The product will supply to all over the world, such as: Danish, Manchester, USA, We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Allow us to work together to write a brilliant new chapter!

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

Write your message here and send it to us