High Quality Hypoid Gears - Hypoid Spiral Gears used in KM-series Speed Reducer – Belon Detail:

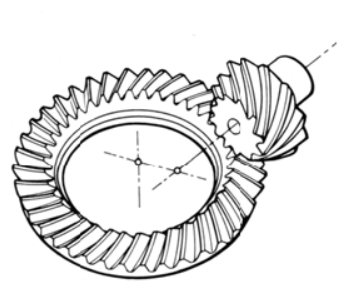

Hypoid Gear Definition

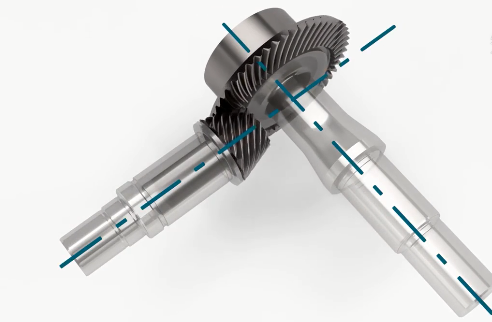

A hypoid is a type of spiral bevel gear whose axis does not intersect with the axis of the meshing gear. Hypoid gearings are used in power transmission products that are more efficient than conventional worm gearing. Transmission efficiency can reach 90% .

Hypoid Gear Feature

The shaft angle of the hypoid gear is 90°, and the torque direction can be changed to 90°. This is also the angle conversion often required in the automobile, airplane, or wind power industry. At the same time, a pair of gears with different sizes and different numbers of teeth are meshed to test the function of increasing torque and decreasing speed, which is commonly referred to as “torque increasing and decreasing speed”. If a friend who has driven a car, especially when driving a manual car when learning to drive, when climbing a hill, the instructor will let you go to a low gear, in fact, it is to choose a pair of gears with a relatively large speed, which is provided at low speeds. More torque, thus providing more power to the vehicle.

1. Adjustable angular change of torque power

2. Higher loads: In the wind power industry, the automotive industry, whether it is passenger cars, SUVs, or commercial vehicles such as pickup trucks, trucks, buses, etc., will use this type to provide greater power.

3. Higher efficiency, lower noise: The pressure angles of the left and right sides of its teeth can be inconsistent, and the sliding direction of the gear meshing is along the tooth width and tooth profile direction, and a better gear meshing position can be obtained through design and technology, so that the entire transmission is under load. The next is still excellent in NVH performance.

4 Adjustable offset distance: Due to the different design of the offset distance, it can be used to meet different space design requirements. For example, in the case of a car, it can meet the ground clearance requirements of the vehicle and improve the pass ability of the car.

Manufacturing Plant

China the first one to import USA UMAC technology for hypoid gears .

Inspection

Reports

We will provide compete quality reports to customers before every shipping like dimension report ,material cert ,heat treat report ,accuracy report and other customer’s required quality files .

Heat Treat report

Flaw Detection report

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

Hypoid Gears

Km Series Hypoid Gears For Hypoid Gearbox

Hypoid Bevel Gear In Industrial Robot Arm

Hypoid Bevel Gear Milling & Mating Testing

Hypoid Gear Set Used In Mountain Bike

Product detail pictures:

Related Product Guide:

The corporate keeps towards the operation concept "scientific administration, superior quality and performance primacy, client supreme for High Quality Hypoid Gears - Hypoid Spiral Gears used in KM-series Speed Reducer – Belon , The product will supply to all over the world, such as: Montreal, Adelaide, The Swiss, We offer OEM services and replacement parts to meet the varying needs of our customers. We offer competitive price for quality products and we will make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.