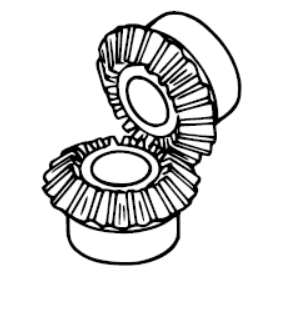

Factory Free sample Straight Bevel Gear - Miter Gear Set With Ratio 1:1 – Belon Detail:

Miter gear working method

Advantages of zero bevel gears are:

1)The force acting on the gear is the same as that of a straight bevel gear.

2) Higher strength and lower noise than straight bevel gears (in general).

3) Gear grinding can be done to obtain high-precision gears .

Manufacturing Plant

Production Process

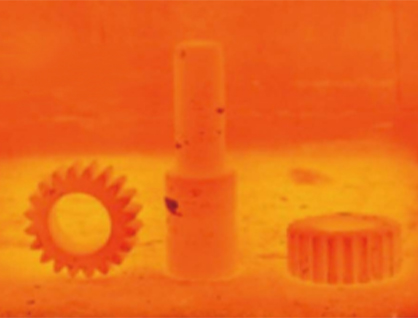

Raw Material

Rough Cutting

Turning

Quenching And Tempering

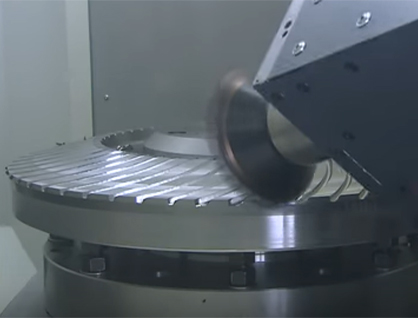

Gear Milling

Heat Treat

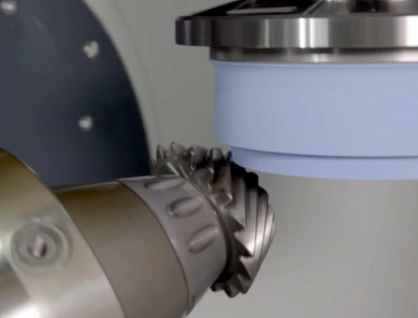

Gear Grinding

Testing

Inspection

Reports

We will provide compete quality reports to customers before every shipping like dimension report ,material cert ,heat treat report ,accuracy report and other customer’s required quality files .

Heat Treat report

Flaw Detection report

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

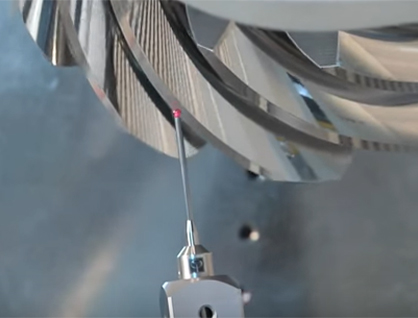

Zero Bevel Gear Milling At Gleason Machine

Product detail pictures:

Related Product Guide:

We enjoy an extremely good status among our prospects for our great merchandise top quality, competitive price and the ideal service for Factory Free sample Straight Bevel Gear - Miter Gear Set With Ratio 1:1 – Belon , The product will supply to all over the world, such as: New Orleans, Oslo, Nepal, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we are going to be pleased to serve you.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!

Write your message here and send it to us