Straight bevel gears are a critical component in heavy duty mining equipment gearboxes, providing reliable power transmission between intersecting shafts. In the mining industry, machinery operates under extreme loads, dusty conditions, and continuous cycles, making gear durability and precision essential.

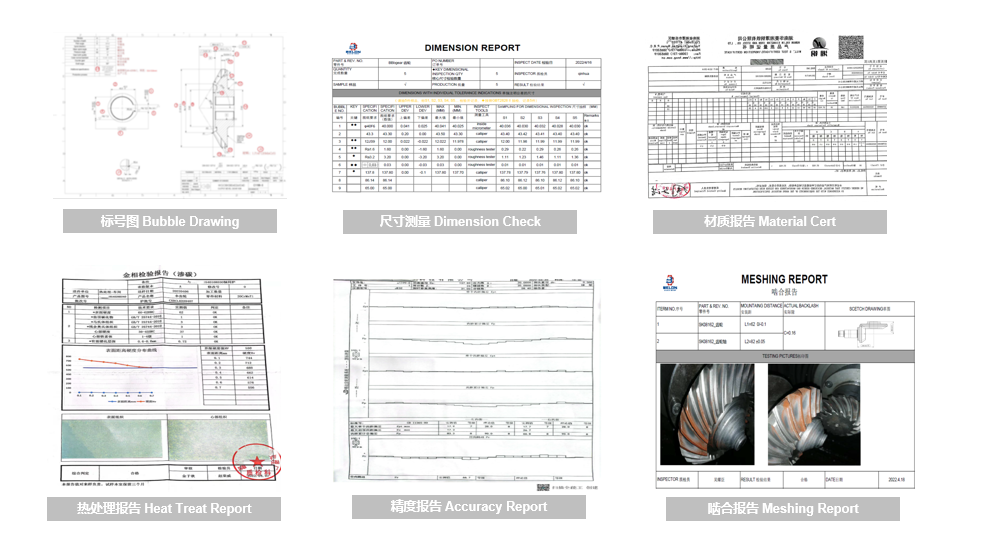

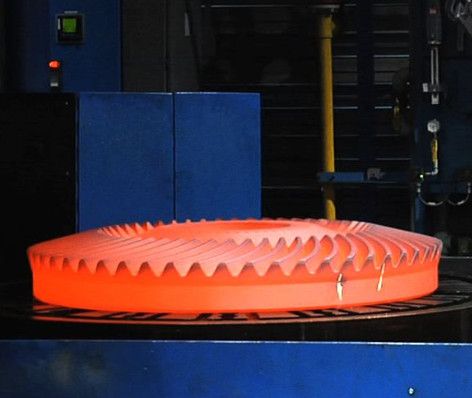

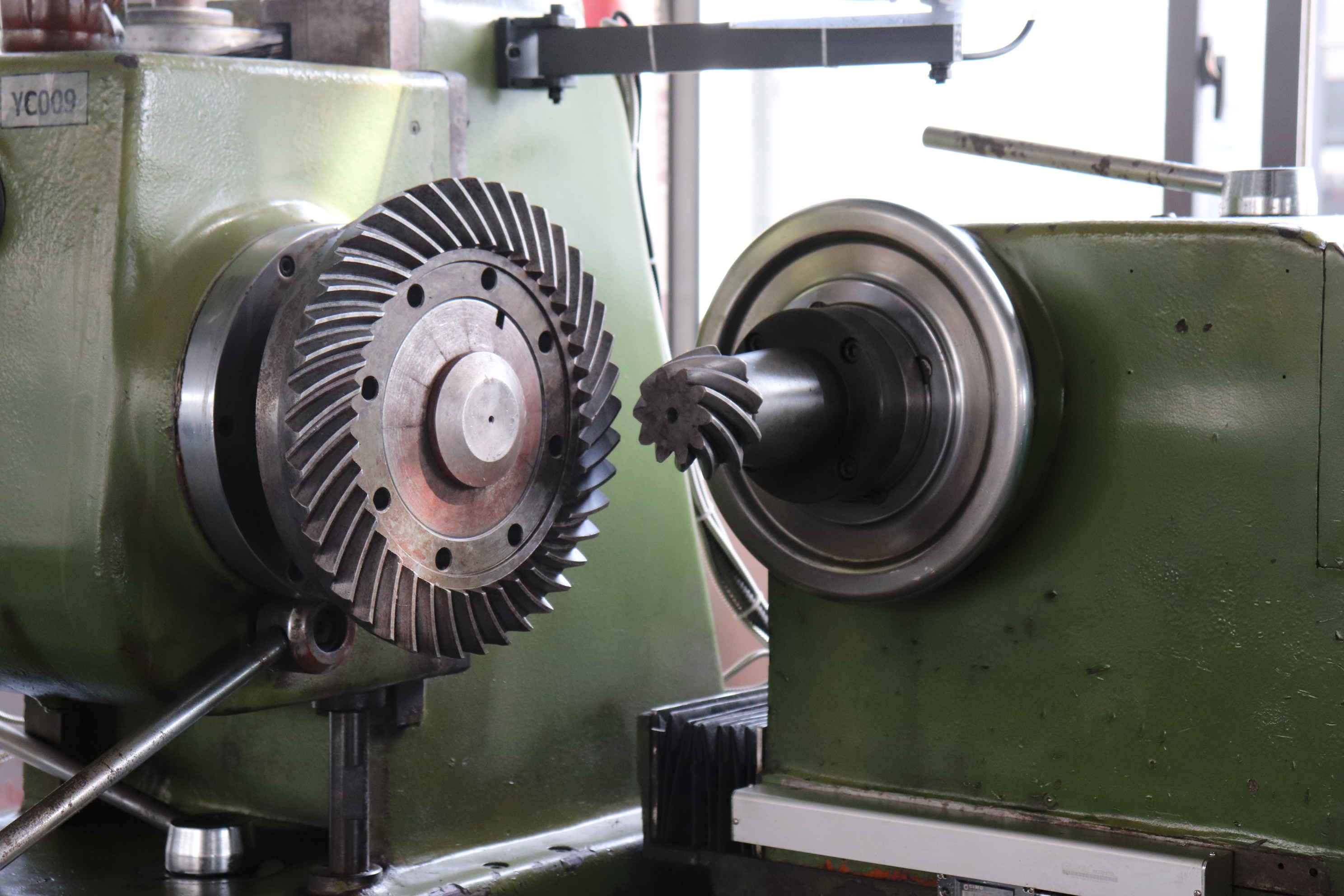

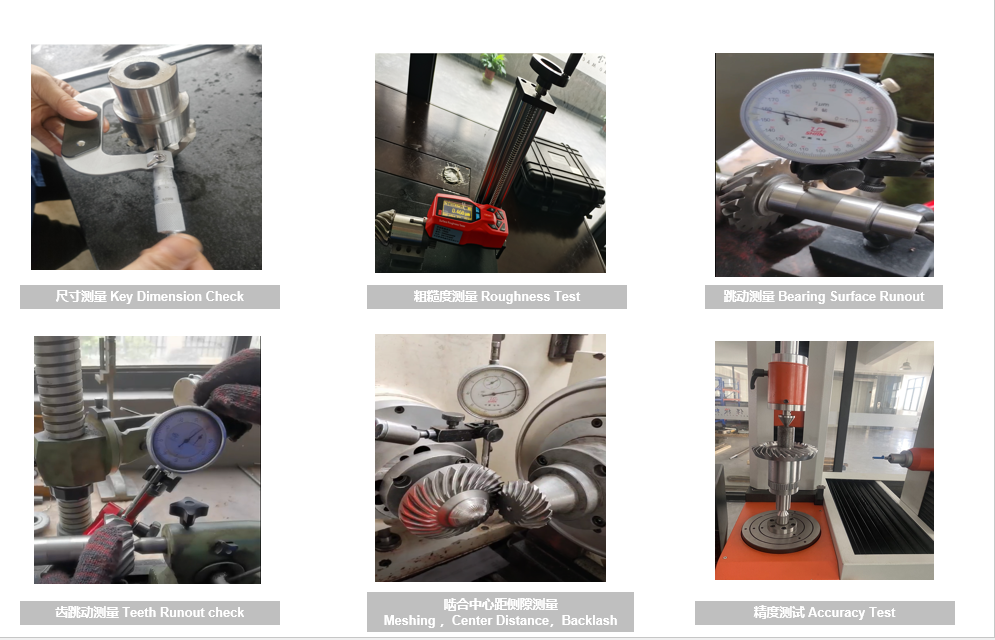

Belon Gear specializes in manufacturing high quality straight bevel gears engineered to withstand the demanding requirements of mining operations. Our gears are produced from premium alloy steels and undergo precision CNC machining to achieve accurate tooth geometry, ensuring smooth meshing and minimal noise during operation.

The straight bevel gear design offers simplicity, efficiency, and high load-carrying capacity, making it ideal for equipment such as crushers, conveyors, drilling rigs, and haul trucks. We customize each gear to match the specific gearbox requirements, whether for new production or as an OEM replacement.