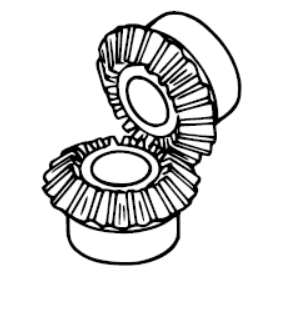

China Manufacturer for Forging Bevel Gears - Miter Gear Set With Ratio 1:1 – Belon Detail:

Miter gear working method

Advantages of zero bevel gears are:

1)The force acting on the gear is the same as that of a straight bevel gear.

2) Higher strength and lower noise than straight bevel gears (in general).

3) Gear grinding can be done to obtain high-precision gears .

Manufacturing Plant

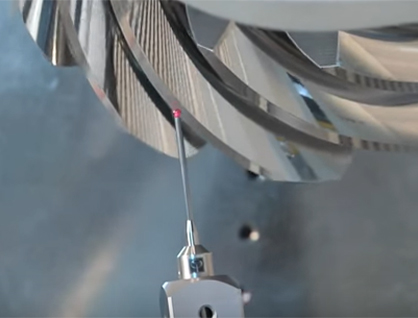

Production Process

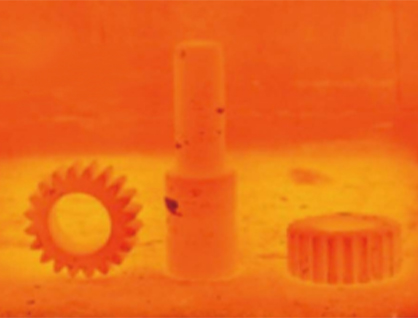

Raw Material

Rough Cutting

Turning

Quenching And Tempering

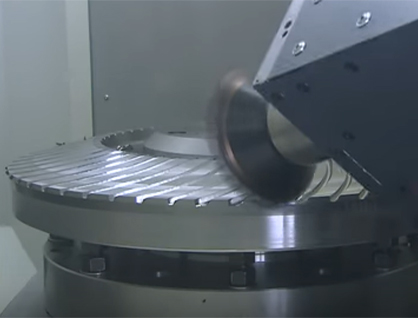

Gear Milling

Heat Treat

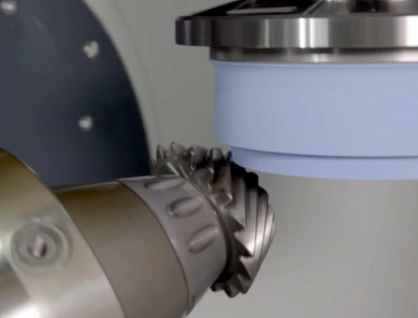

Gear Grinding

Testing

Inspection

Reports

We will provide compete quality reports to customers before every shipping like dimension report ,material cert ,heat treat report ,accuracy report and other customer’s required quality files .

Heat Treat report

Flaw Detection report

Packages

Inner Package

Inner Package

Carton

Wooden Package

Our video show

Zero Bevel Gear Milling At Gleason Machine

Product detail pictures:

Related Product Guide:

Sticking to the perception of "Creating products of top of the range and earning mates with people today from all over the world", we constantly put the desire of consumers in the first place for China Manufacturer for Forging Bevel Gears - Miter Gear Set With Ratio 1:1 – Belon , The product will supply to all over the world, such as: Miami, Kazakhstan, Kenya, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

Write your message here and send it to us